Method for producing double-wall corrugated tube

A manufacturing method and technology for corrugated pipes, which are applied in the directions of hoses, pipes, tubular objects, etc., can solve the problems of high cost and complicated forming processes, and achieve the effect of preventing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

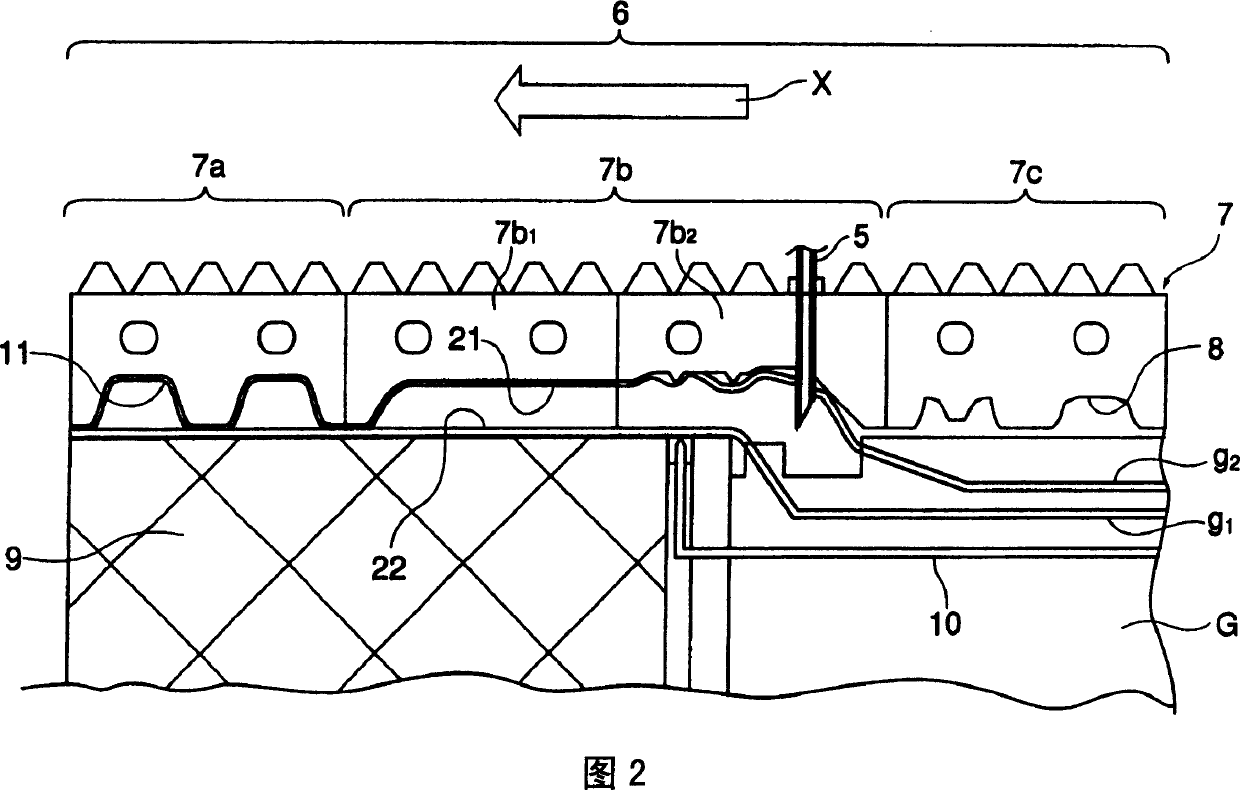

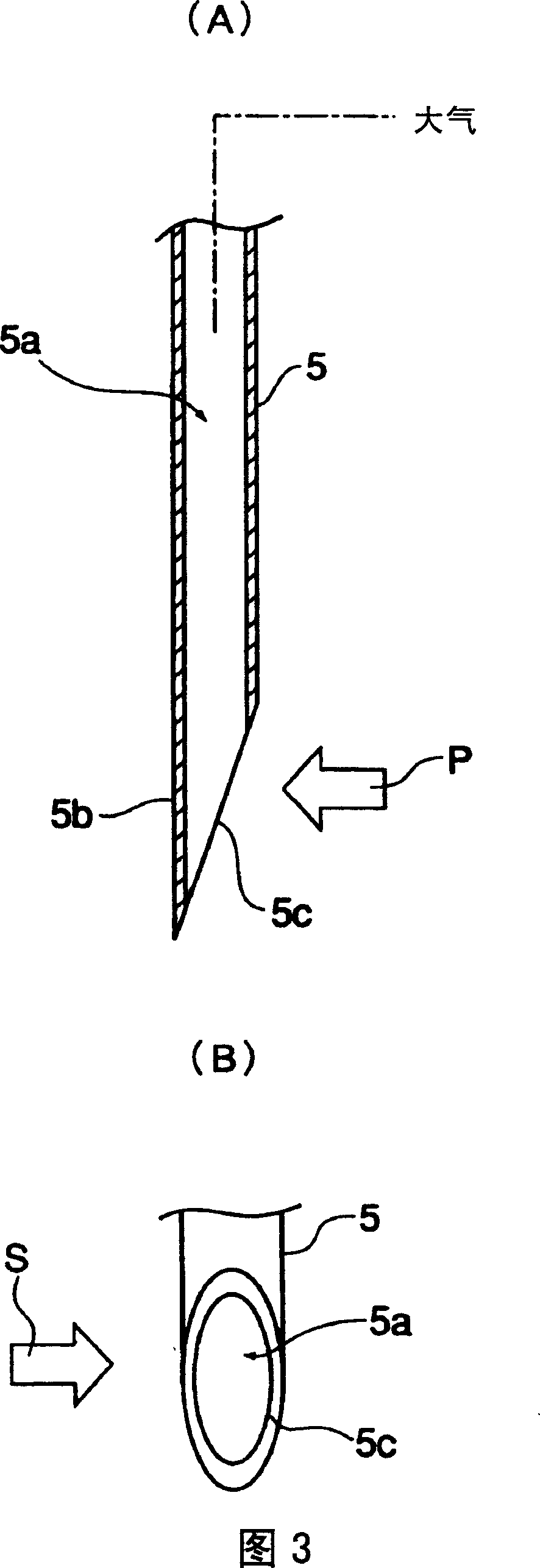

[0034] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

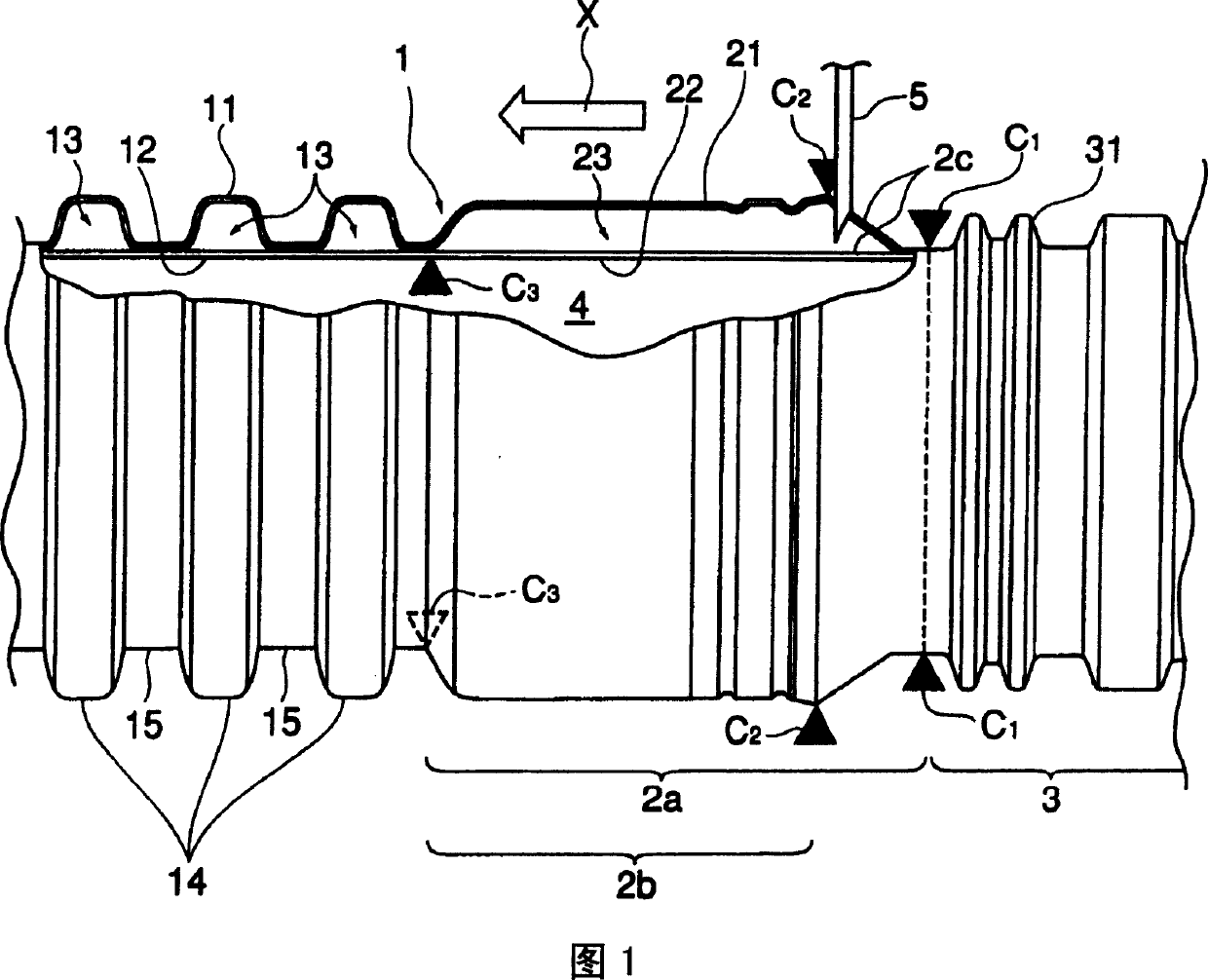

[0035] First, FIG. 1 is a partial external view of the periphery of the plug portion of a double-wall corrugated pipe (hereinafter simply referred to as "corrugated pipe") extruded in a series of connected states by the manufacturing method of the present invention.

[0036] The corrugated tube 1 is provided with an outer wall 11 having a concavo-convex shape formed mainly to increase strength, and a cylindrical inner wall 12 thermally welded to an inner wall surface portion of the outer wall 11 .

[0037] The outer wall 11 has the aforementioned concavo-convex shape in which the convex portions 14 and the concave portions 15 are repeatedly formed, and an annular hollow chamber 13 closed by the outer wall 11 and the inner wall 12 is formed inside each convex portion 14 .

[0038] Moreover, the symbol 4 in FIG. 1 represents the inner hollow portion inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com