Laser light beam collimation device and manufacturing method thereof

A manufacturing method and laser technology, applied in the field of lasers, can solve the problems that the relative position parameters of the laser and the collimating mirror cannot be within the optimal range, the distance cannot be within the predetermined range, and the angle of the collimating mirror cannot be adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] A laser beam collimation device and a manufacturing method thereof according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0044] In order to achieve the above object, embodiments of the present invention adopt the following technical solutions:

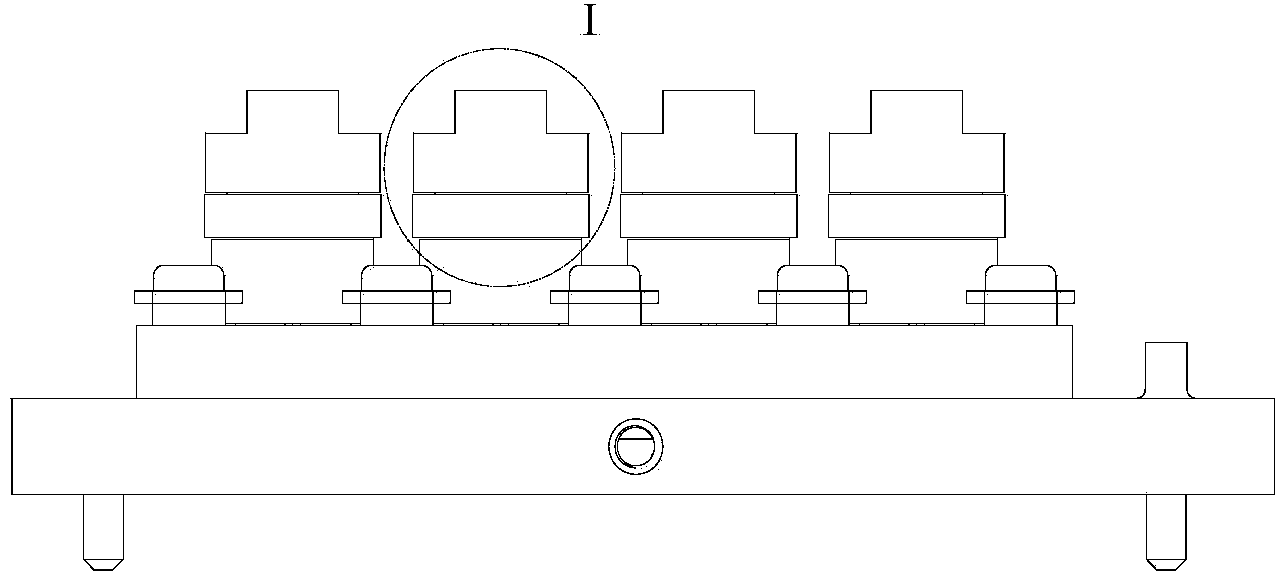

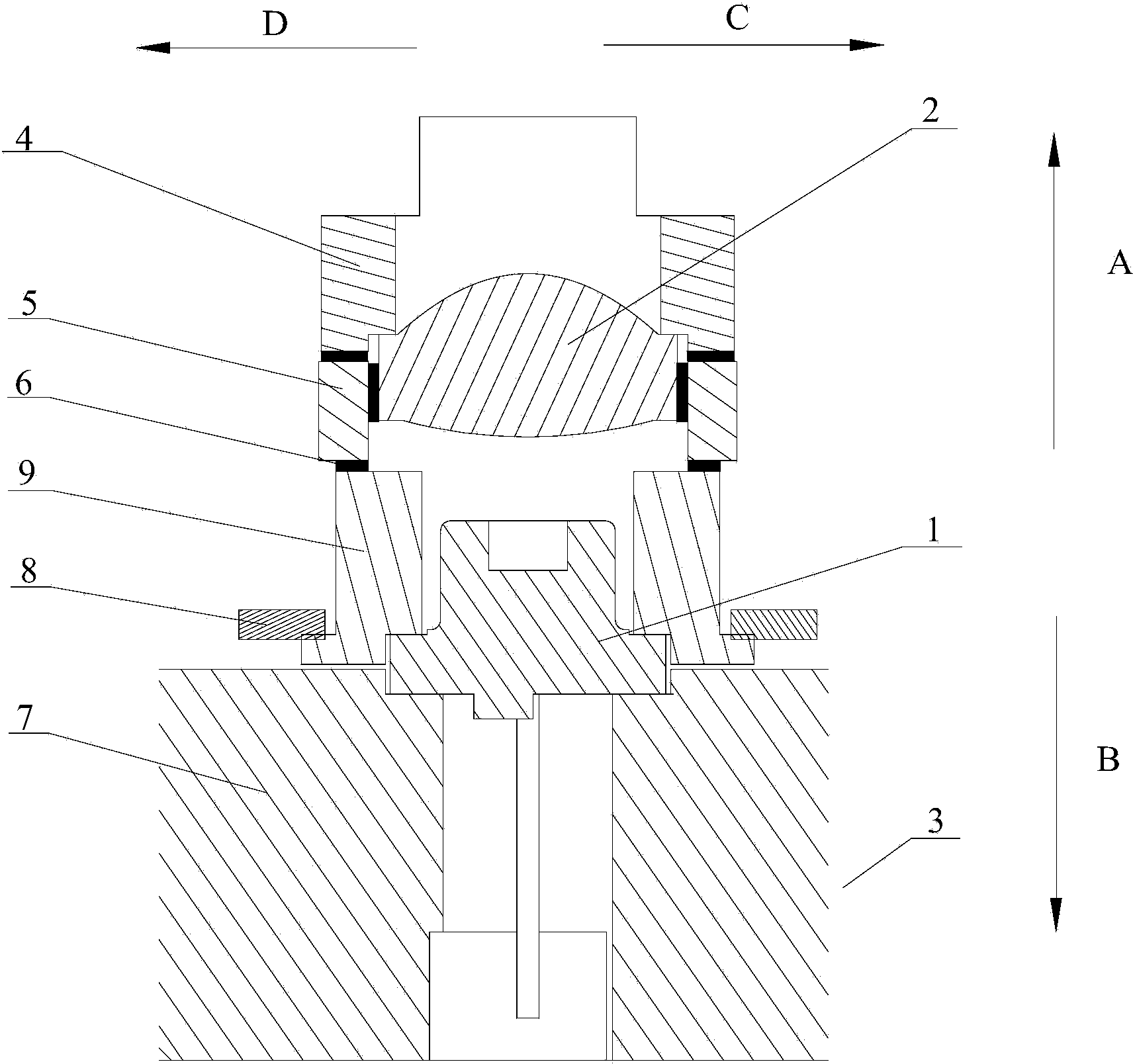

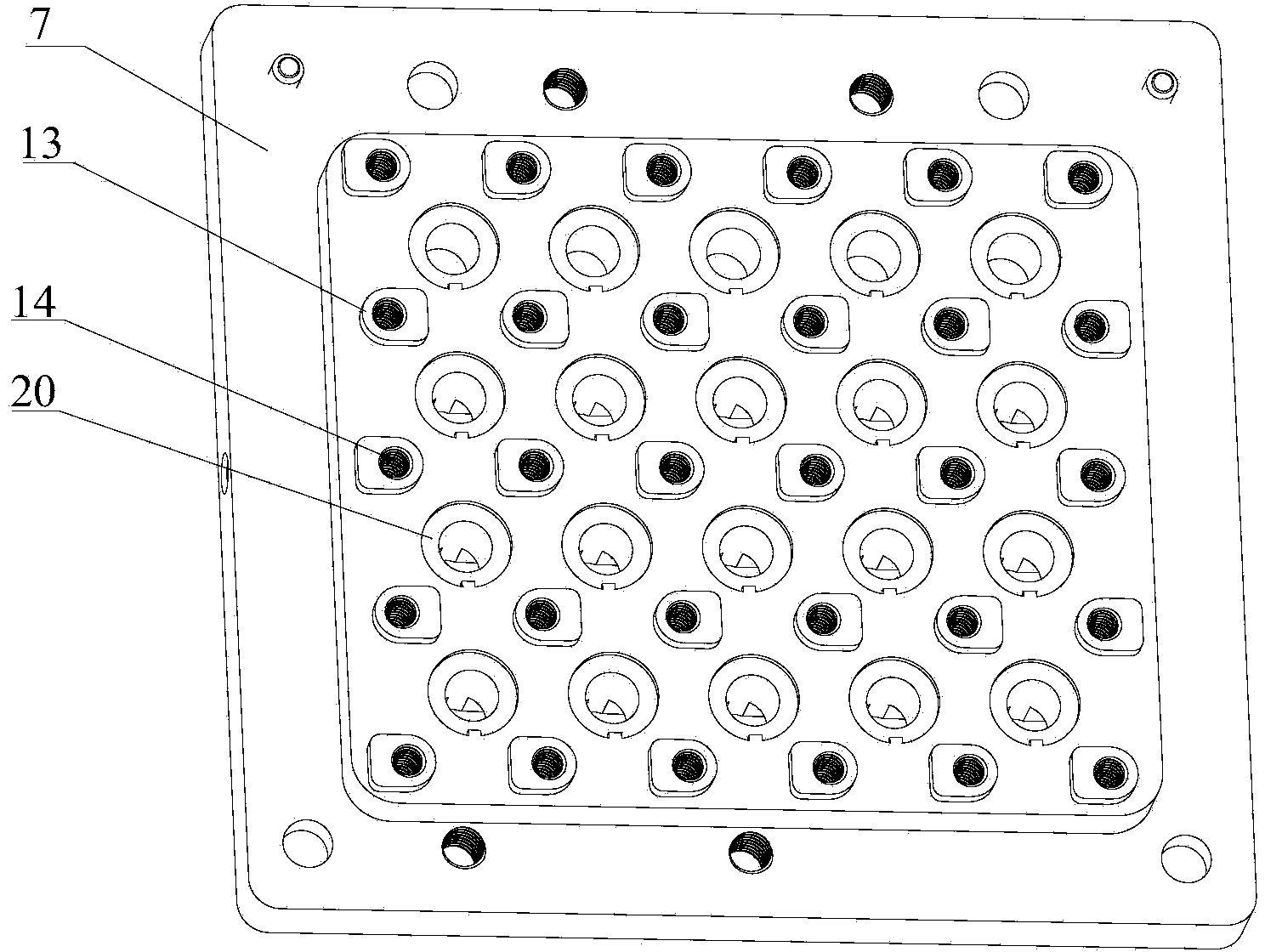

[0045] As shown in Figure 1(a) and Figure 1(b), the laser beam collimation device provided by the embodiment of the present invention includes a laser 1 and a collimating mirror 2 opposite to the laser 1, the laser 1 is fixed on the laser seat 3, and the collimator The straight mirror 2 is fixed on the collimating mirror base 4, and a light-transmitting rigid ring 5 is arranged between the collimating mirror base 4 and the laser base 3, and between the light-transmitting rigid ring 5 and the laser base 3 and / or the collimating mirror base 4 There is a first gap between them, and the first gap is filled with photosensitive adhesive 6 .

[0046] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com