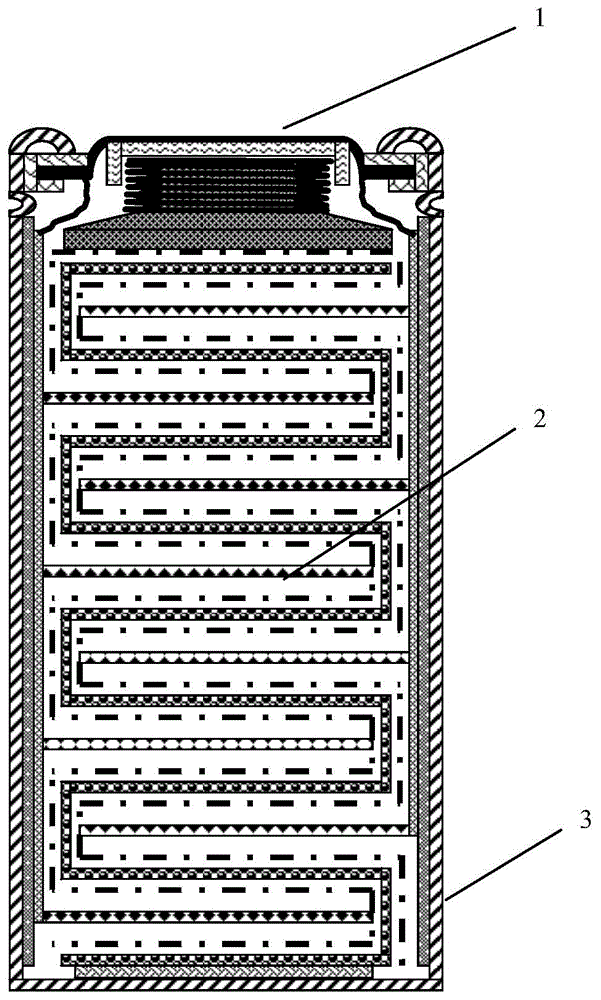

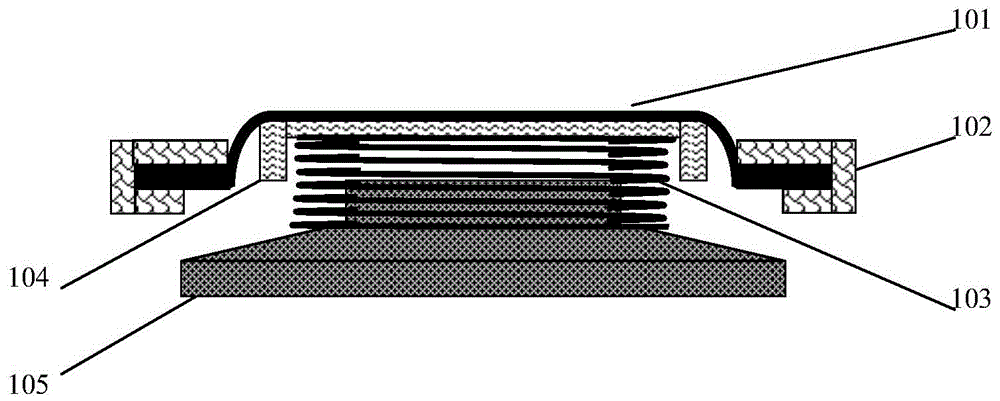

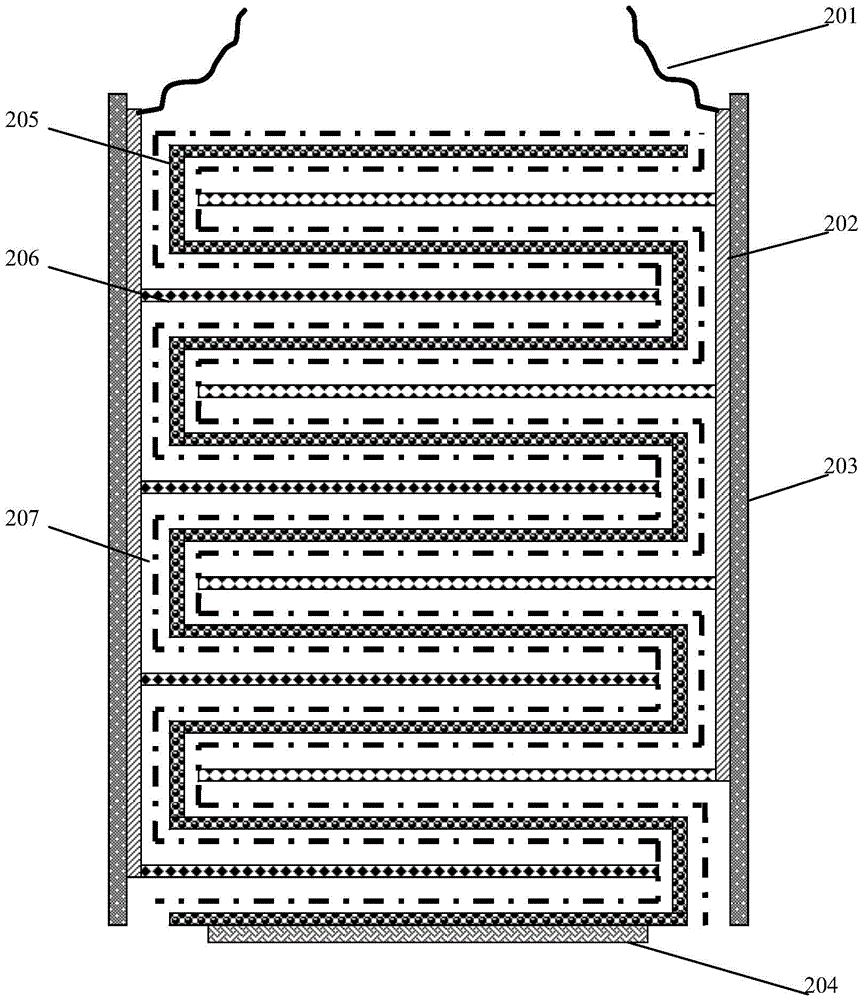

Laminated cylindrical lithium ion battery and fabrication method thereof

A technology of lithium-ion batteries and manufacturing methods, which is applied to the structural field of cylindrical lithium-ion battery cells, and can solve problems such as increased internal resistance of cells, heat export, and battery safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1 Preparation of 18650 type lithium iron phosphate cathode material battery

[0065] Positive electrode ratio: 945g LiFePO 4 +7g of PVDF (5130)+2gSuper_p+2gKS_6; using a pulper, first add 1200g of NMP, then add 7g of PVDF (5130) and stir at high speed for 3h, 2g of Super_p and 2g of KS_6 for 3h at high speed, and 945g of LiFePO 4 Stir at high speed for 4h.

[0066] The stirred positive electrode slurry is coated on the positive electrode current collector on the coating machine to obtain a single-sided surface density of 150g / m 2 , double-sided density 300g / m 2 positive pole piece. The above-mentioned coated positive electrode sheet is rolled by a pair of rollers to obtain a compacted 2.3g / cm 3 Positive pole piece, the thickness of the pole piece is 146 μ m (thickness of aluminum foil is 16 μ m) at this moment, stand-by.

[0067] Negative electrode ratio: 958.5 negative electrode active material + 5.4g SBR (solid content 50%) + 3.6g CMC + 2g Super_p; using ...

Embodiment 2

[0074] Example 2 Preparation of 18650 type ternary cathode material battery

[0075] Positive electrode ratio: 991g of ternary positive electrode material + 5g of PVDF (5130) + 2g of Super_p + 2g of KS_6; using a pulper, first add 550g of NMP, then add 5g of PVDF (5130) and stir at high speed for 3 hours , 2g of Super_p and 2g of KS_6 were stirred at high speed for 3h, and 991g of ternary cathode material was stirred at high speed for 4h.

[0076] The stirred positive electrode slurry is coated on a coating machine to obtain a density of 173g / m on one side 2 , double-sided density 345g / m 2 positive pole piece. The above-mentioned coated positive electrode sheet is rolled by a pair of rollers to obtain a compacted 3.55g / cm 3Positive pole piece, the thickness of the pole piece at this moment is 106 μ m (the thickness of aluminum foil is 16 μ m), stand-by.

[0077] Negative electrode ratio: 958.5g of negative electrode active material + 5.4g of SBR (solid content 50%) + 3.6g ...

Embodiment 3

[0085] Example 3 Preparation of 18650 type lithium manganate cathode material battery

[0086] Positive electrode ratio: 945g of lithium manganate + 7g of PVDF (5130) + 2g of Super_p + 2g of KS_6; using a pulper, first add NMP with a total weight of 600g of positive electrode powder, and then add 7g of PVDF (5130) in turn High-speed stirring for 3h, 2g of Super_p and 2g of KS_6 high-speed stirring for 3h, 945g of LiFePO 4 Stir at high speed for 4h.

[0087] The stirred positive electrode slurry is coated on a coating machine to obtain a density of 212g / m on one side 2 , double-sided density 423g / m 2 positive pole piece. The above-mentioned coated positive electrode sheet is rolled by a pair of rollers to obtain a compacted 3.1g / cm 3 The positive pole piece, the thickness of the pole piece at this time is 152 μm (the thickness of the aluminum foil is 16 μm), stand-by.

[0088] Negative electrode ratio: 958.5g of negative electrode active material + 5.4g of SBR (solid conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com