Self adaptive glue discharging control method

A control method and self-adaptive technology, which is applied in the field of glue removal control to establish mixing process parameters and regression models, and can solve problems such as potential safety hazards, high product return rate, and long test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

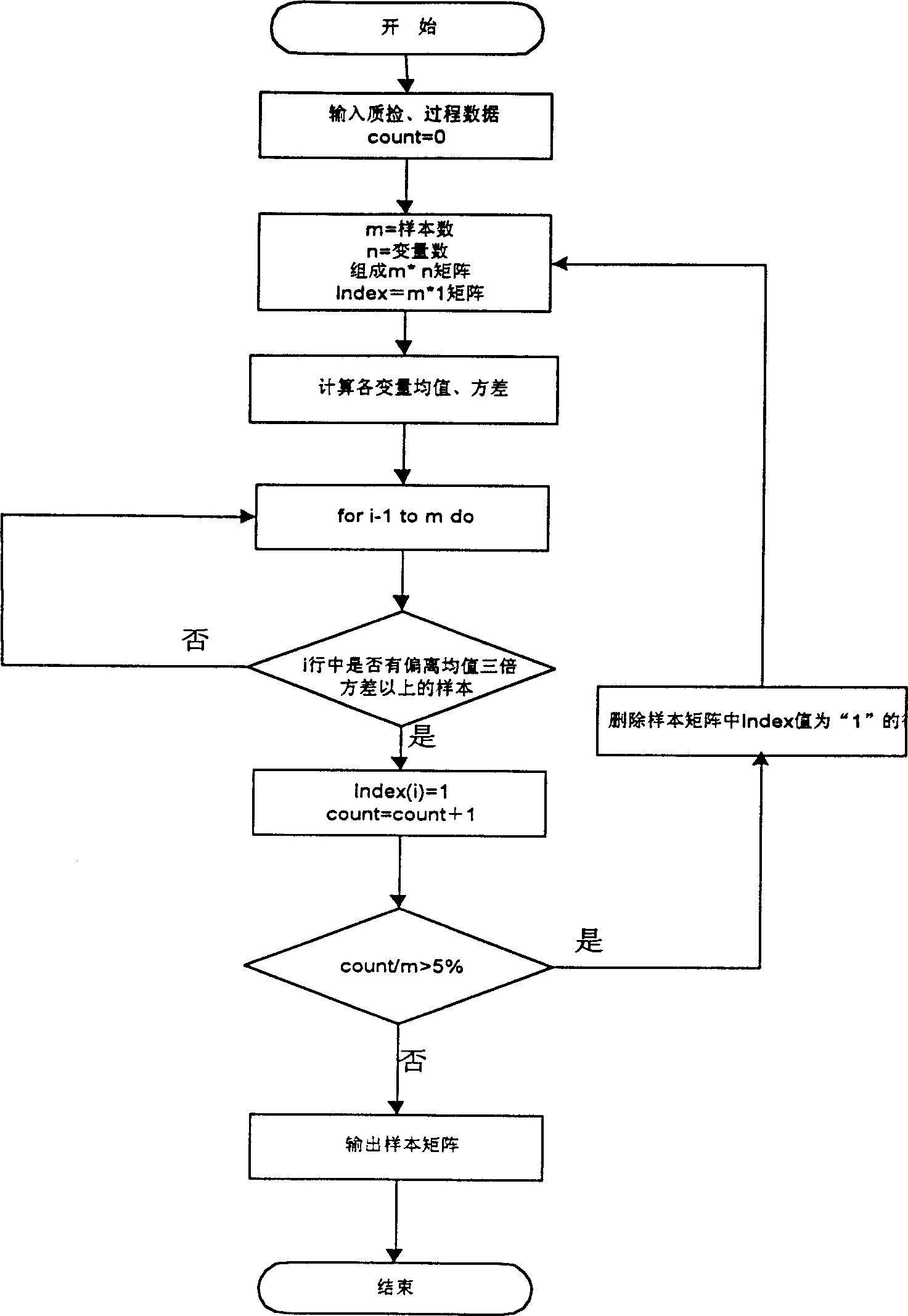

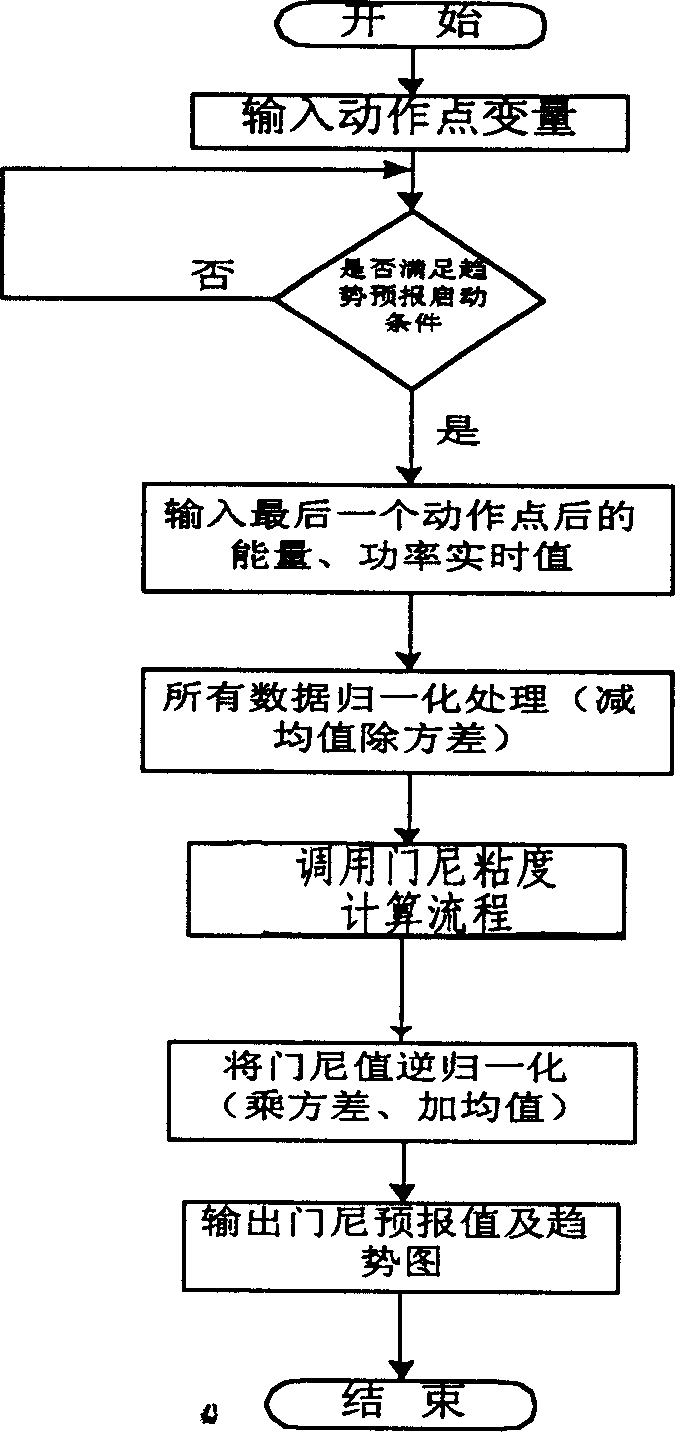

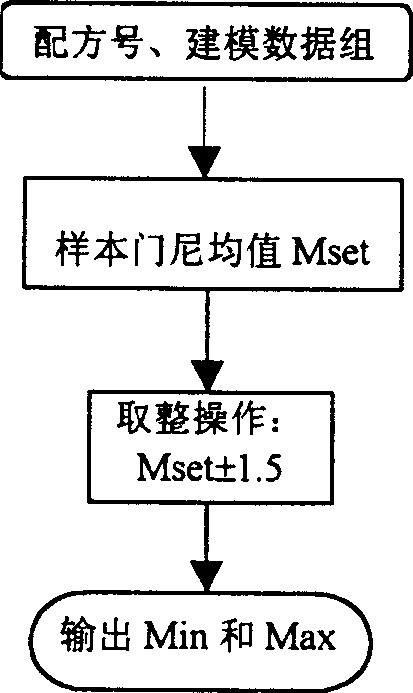

[0072] In the self-adaptive glue removal control method of the present invention, the on-line forecasting process flow for controlling the quality of the rubber material mainly includes two parts: the data preprocessing flow and the real-time calculation flow of the predicted value.

[0073] Such as figure 1 As shown, the data preprocessing process is:

[0074] The first step is to input quality inspection and process control data to determine the number of samples m, the number of variables n, and initialize the count value to 0. The variables are effective variables that can accurately reflect the degree of rubber mixing, such as temperature, power, energy and other values;

[0075] The second step is to establish a data matrix of m*n, and set the parameter to 1, that is, initialize the data model of the matrix as m*1;

[0076] The third step is to calculate the mean and variance of each variable in all provided samples one by one;

[0077] The fourth step is to judge whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com