Hollow casing for in-site casting concrete filling

A technology of hollow carcass and cast-in-place concrete, which is applied in the on-site preparation of building components, formwork/formwork/work frame, structural elements, etc., which can solve the problems of building component dislocation, inconvenient layout, and affecting construction efficiency. Achieve the effect of anti-floating positioning, large anchoring force, and convenient application and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

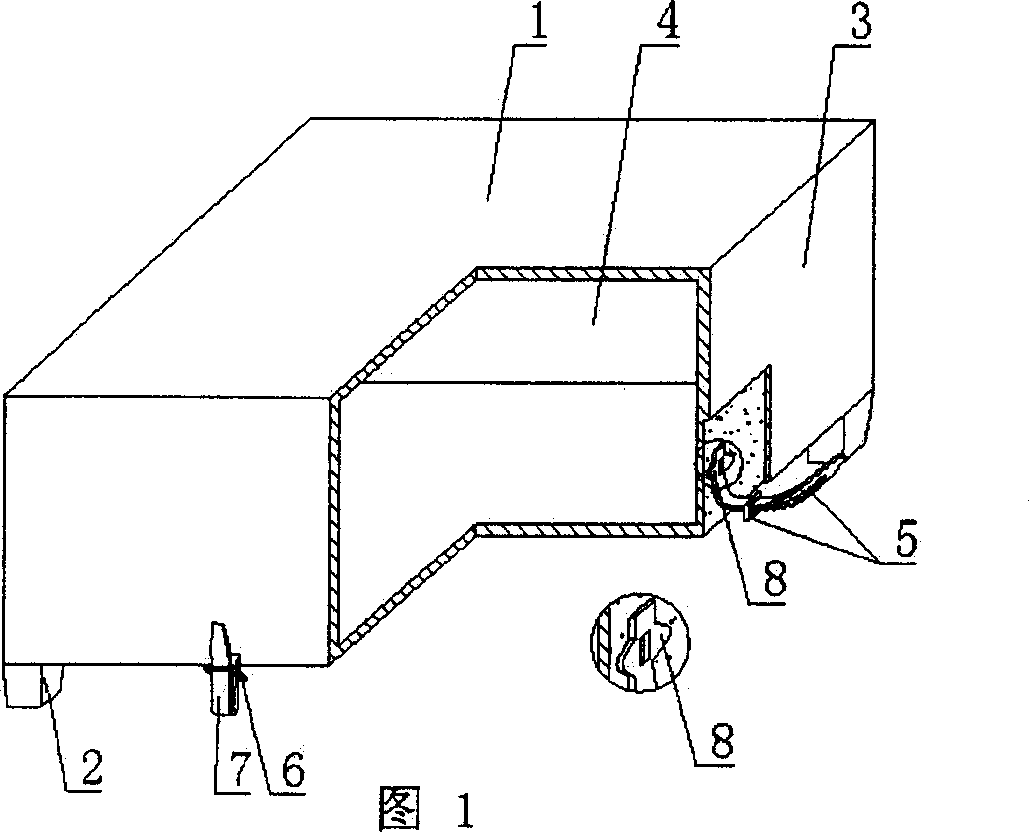

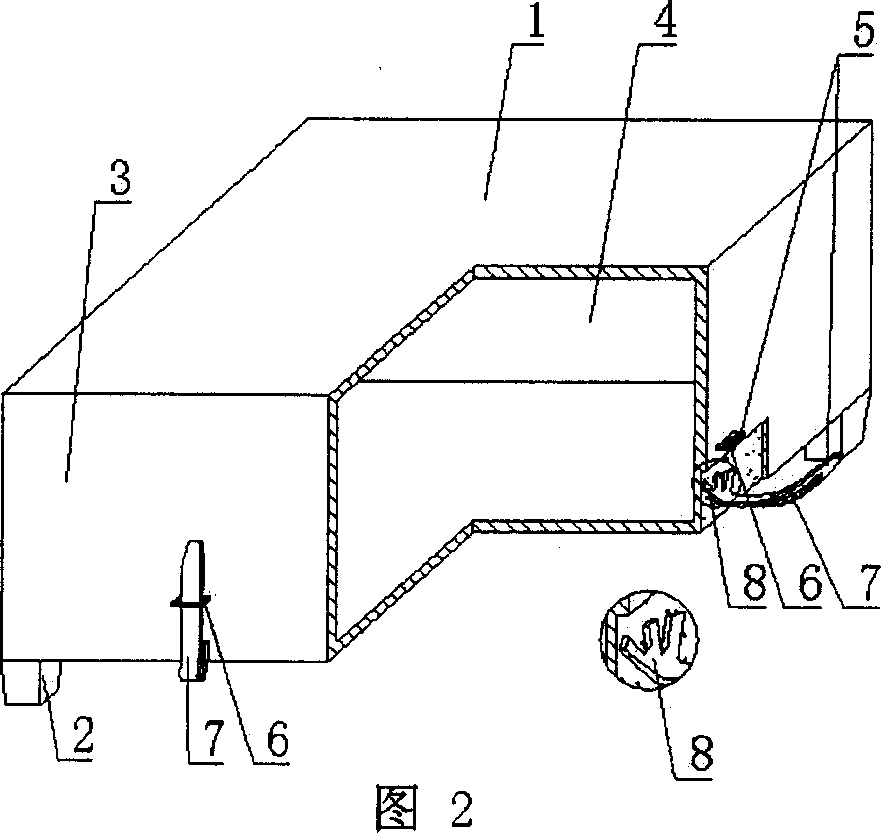

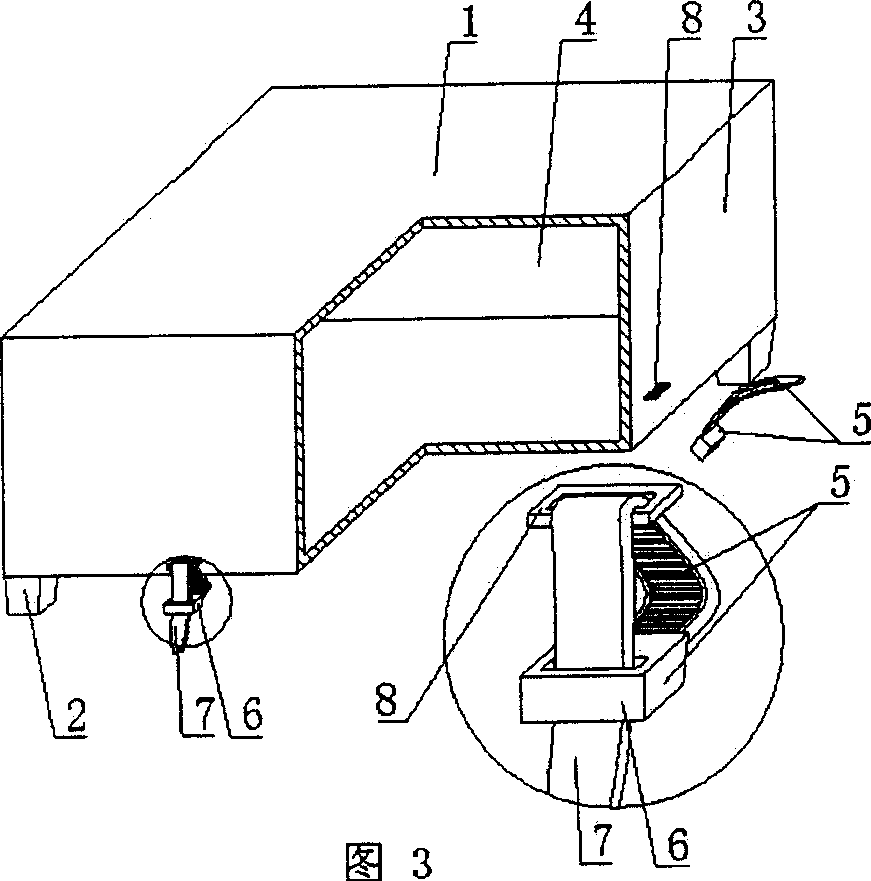

[0091] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0092] As shown in the accompanying drawings, the present invention includes a hollow carcass 1 and a support foot 2. The support foot 2 is arranged on the outer wall 3 of the bottom surface of the hollow carcass 1, and the outer wall 3 encloses the hollow carcass 1 with a cavity 4. Its characteristics The hollow carcass 1 or / and the support foot 2 are provided with a locking member 5, the locking member 5 includes a self-locking hole 6 and a self-locking strip or strip 7, and the locking member 5 is supported by an anchor member 8 Anchored in the hollow carcass 1 or the locking member 5 is connected with the anchoring member 8 anchored in the hollow carcass 1 . In each accompanying drawing, 1 is a hollow carcass, 2 is a support foot, 3 is an outer wall, 4 is a cavity, 5 is a locking member, 6 is a self-locking hole, 7 is a self-locking strip or strip, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com