Railroad rail stress testing method

A technology for stress testing and rails, which is applied in the direction of measuring force, measuring devices, instruments, etc., can solve the problems of heavy driving influence, failure to obtain stress change process, and difficulty in automatic detection, etc., and achieve the effect of preventing rail swelling or breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

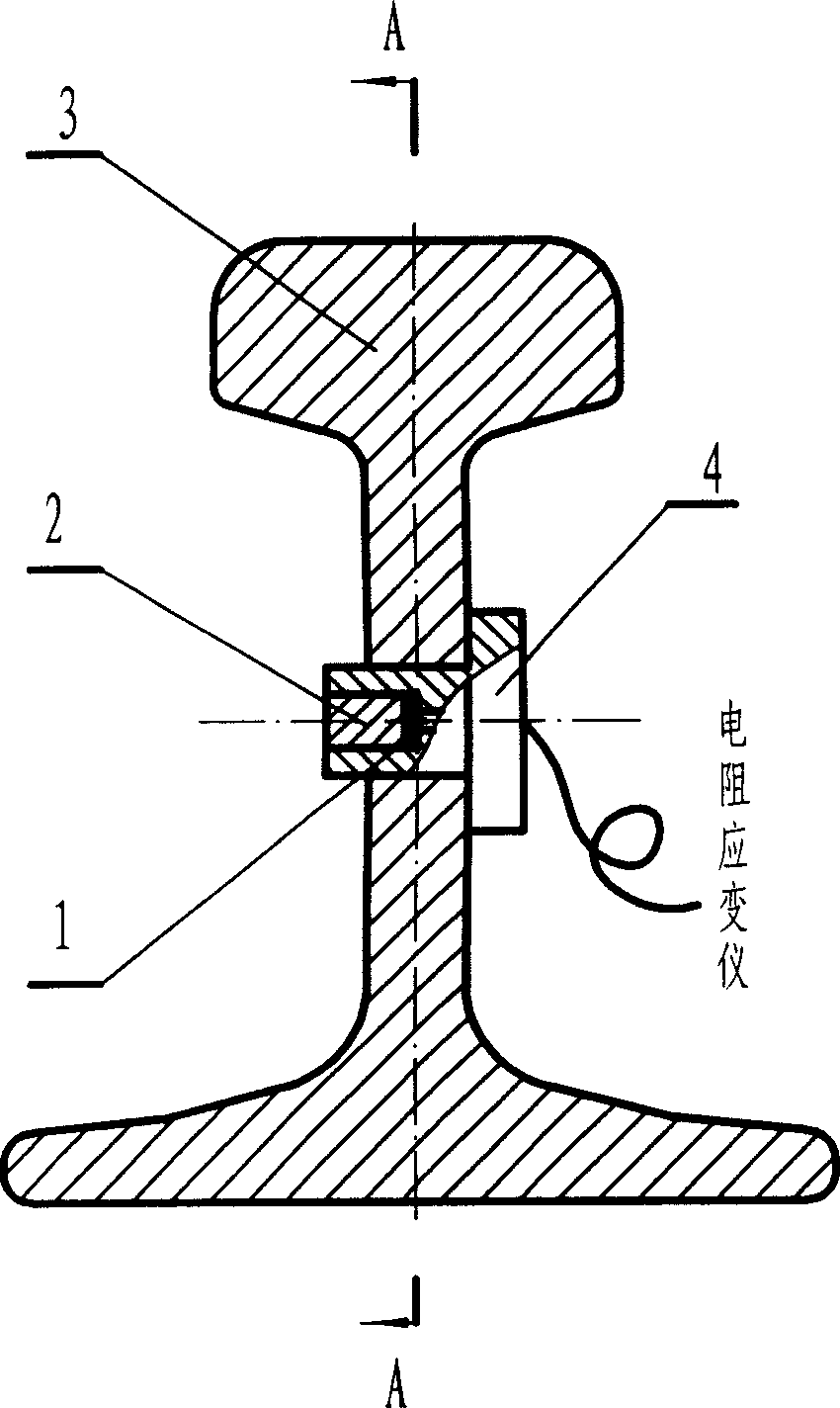

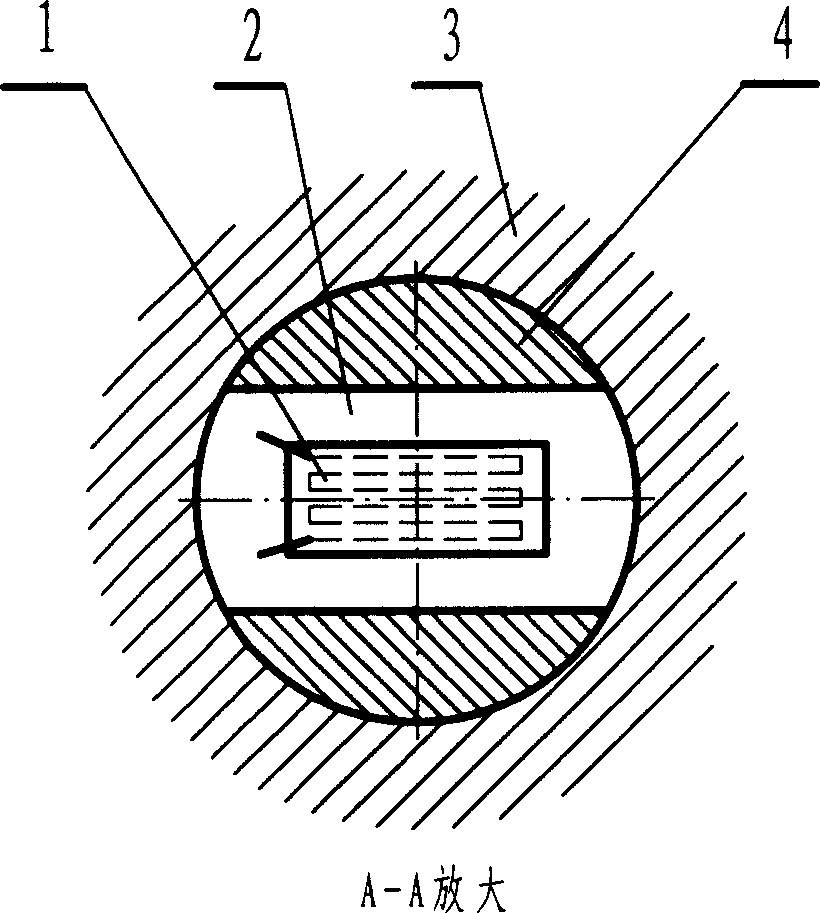

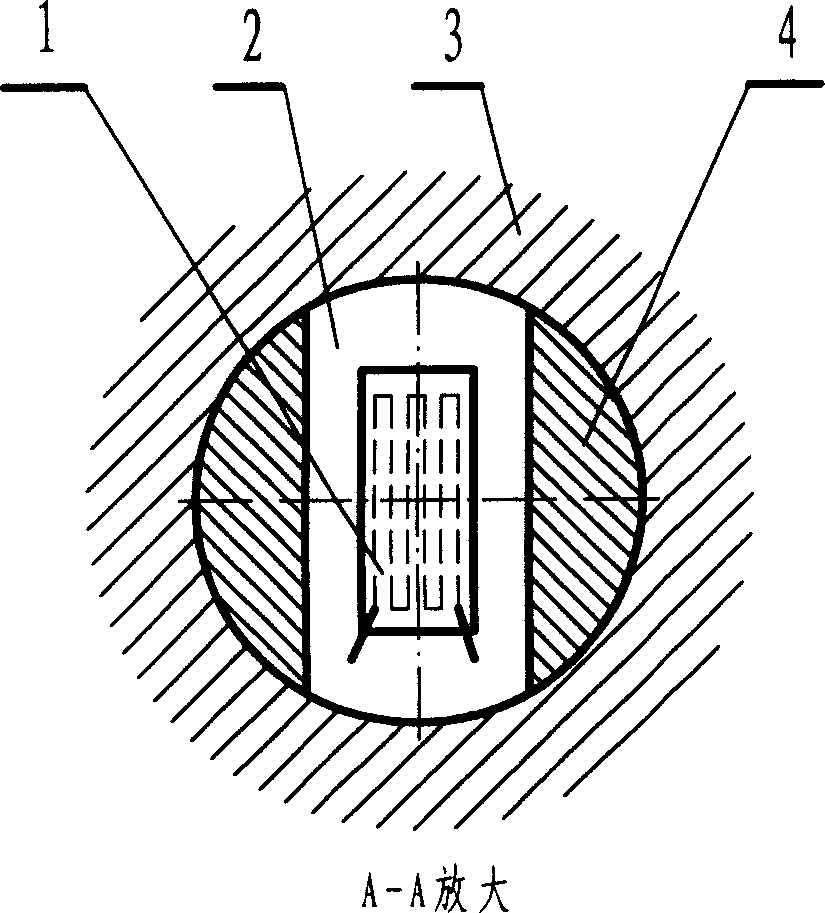

[0018] Such as figure 1 As shown, the rail waist part of the tested rail 3 is processed by drilling-expanding-twisting-a high-precision hole, and its diameter is suggested to be 20 millimeters by railway technical regulations. A special force sensor is assembled in the hole by pressing in. The sensor is composed of the sensor body 4 and the force block 2, and the strain gauge 1 is pasted on the force block 2, in order to avoid the error caused by the difference in temperature coefficient between the sensor and the rail. , the force block 2 and the sensor body 4 are made of the same material as the measured rail 3, and the test recording equipment connected to the sensor is a resistance strain gauge. Before the sensor is used, use a tensile testing machine to calibrate the relationship between the different stresses on the rail and the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com