Device and method for monitoring state of filter element

A filter element and state technology, which is applied in the field of devices monitoring the state of the filter element, can solve the problems of unsafe, inaccurate, and unrealistic large-scale manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments disclosed below are not intended to exhaust or limit the invention in the precise form described below. Rather, these embodiments were chosen to be illustrated so that those of ordinary skill in the art can derive inspiration therefrom.

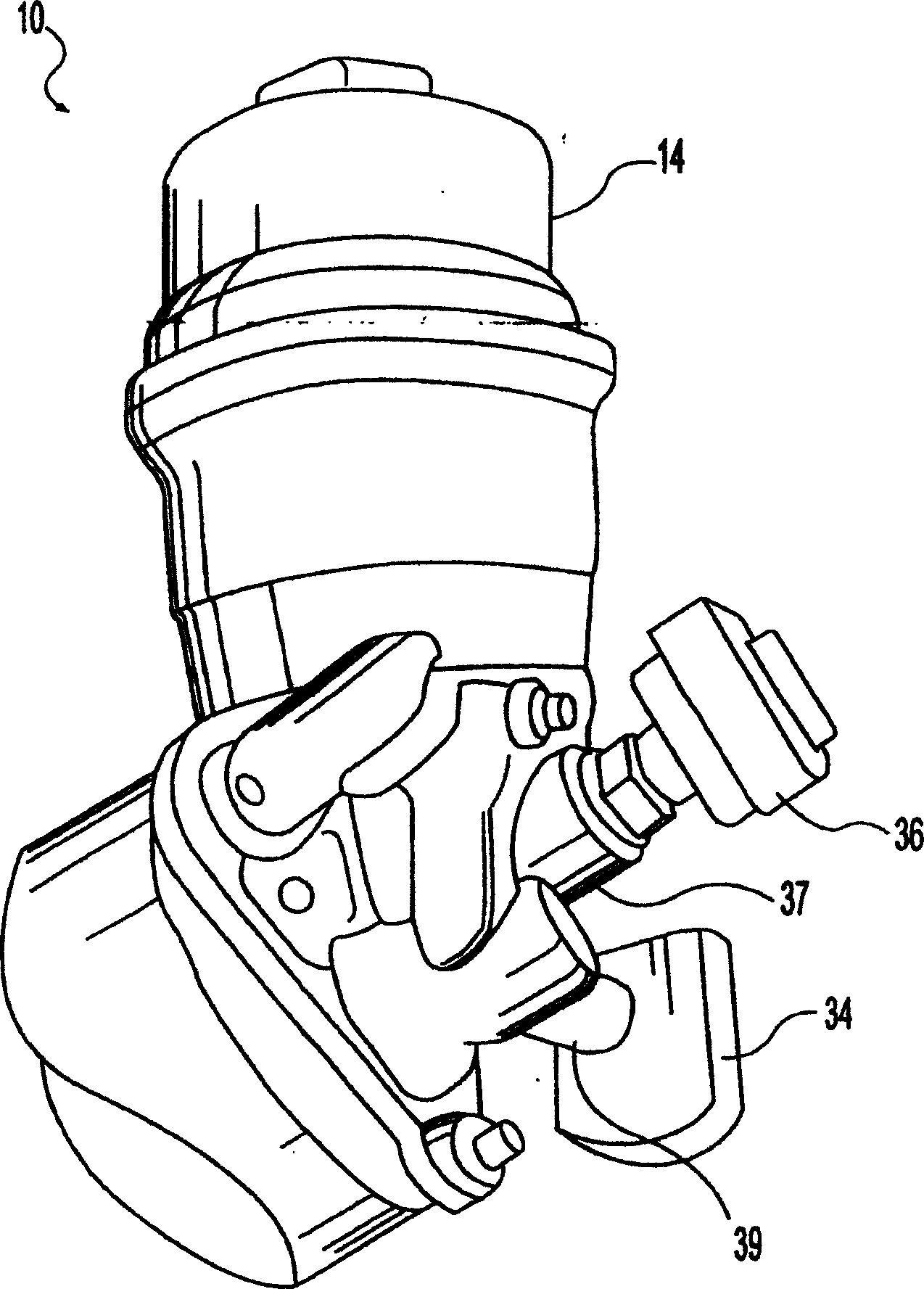

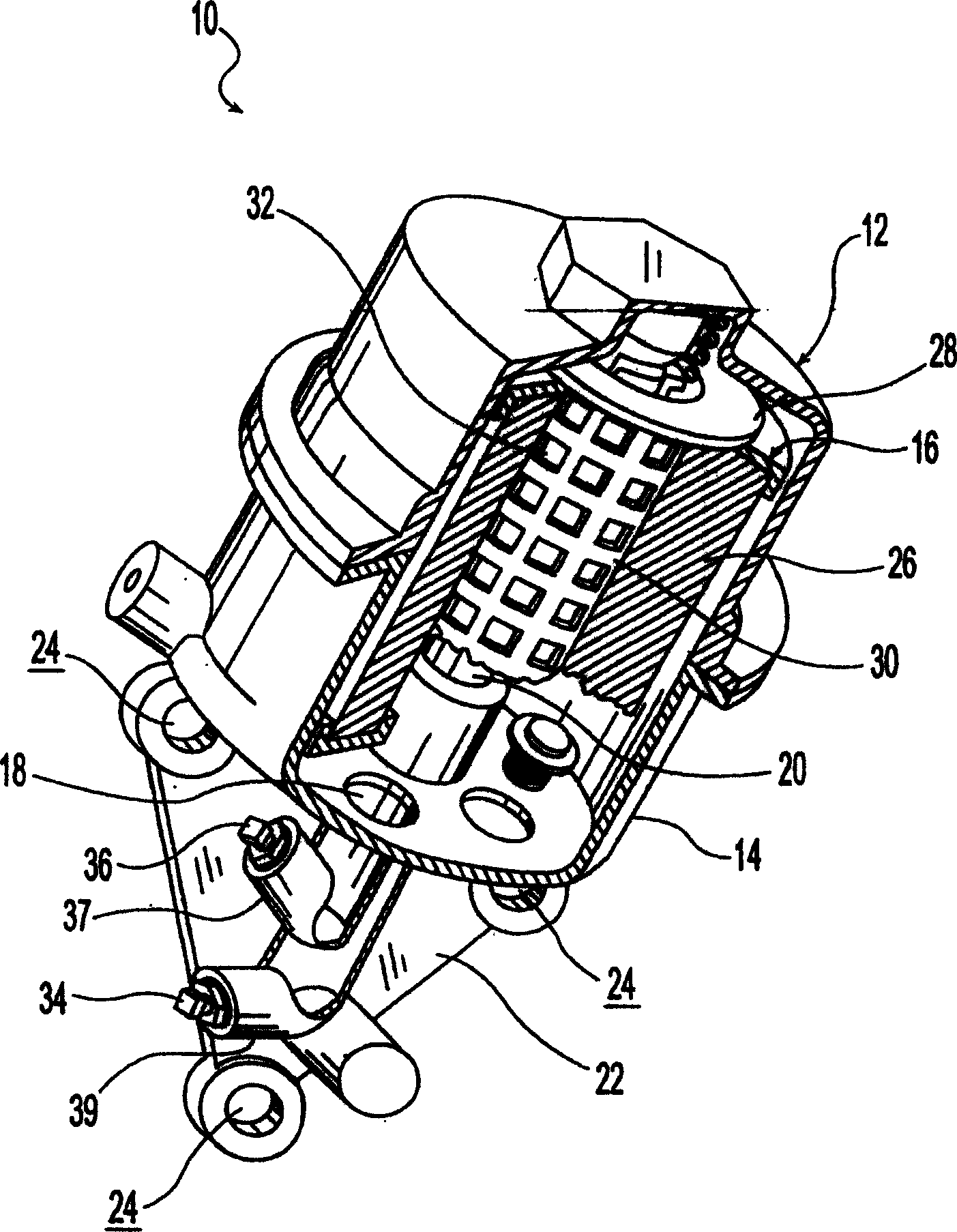

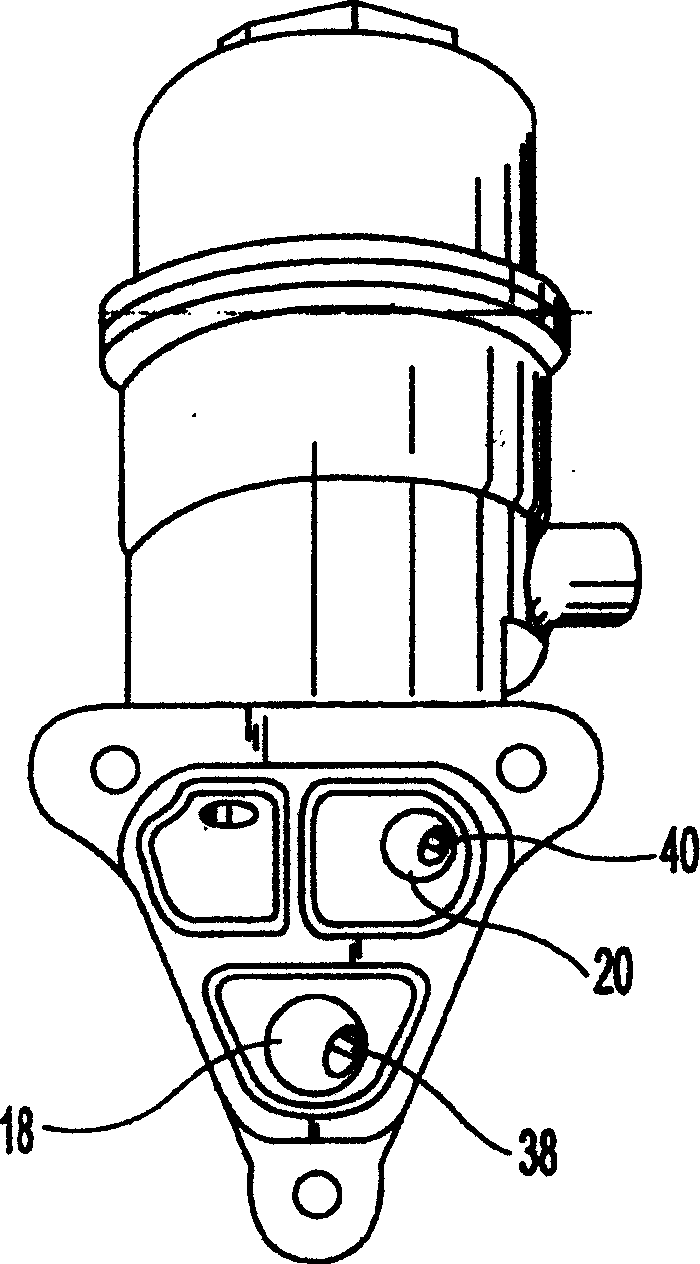

[0019] Figure 1-Figure 3 A fluid filter system 10 in one embodiment of the present invention is described. The filter system 10 includes a cartridge filter assembly 12 generally having a housing 14 , a cartridge cartridge 16 disposed in the housing 14 , at least one inlet passage 18 and one outlet passage 20 . The filter assembly 12 also includes a mounting flange 22 having mounting holes 24 through which mounting screws (not shown) can extend to attach the filter assembly 12 to an engine)))) on the group body. Inlet passage 18 and outlet passage 20 communicate fluid between the engine and the interior of housing 14 when mounted on the engine block body. The filter cartridge 16 includes a filter element 26 with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com