Flexible diaphragm with integrated coil

A vibrating membrane and coil technology, applied in the direction of flat vibrating membrane, telephones with user guidance/use, non-planar vibrating membrane/paper cone, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

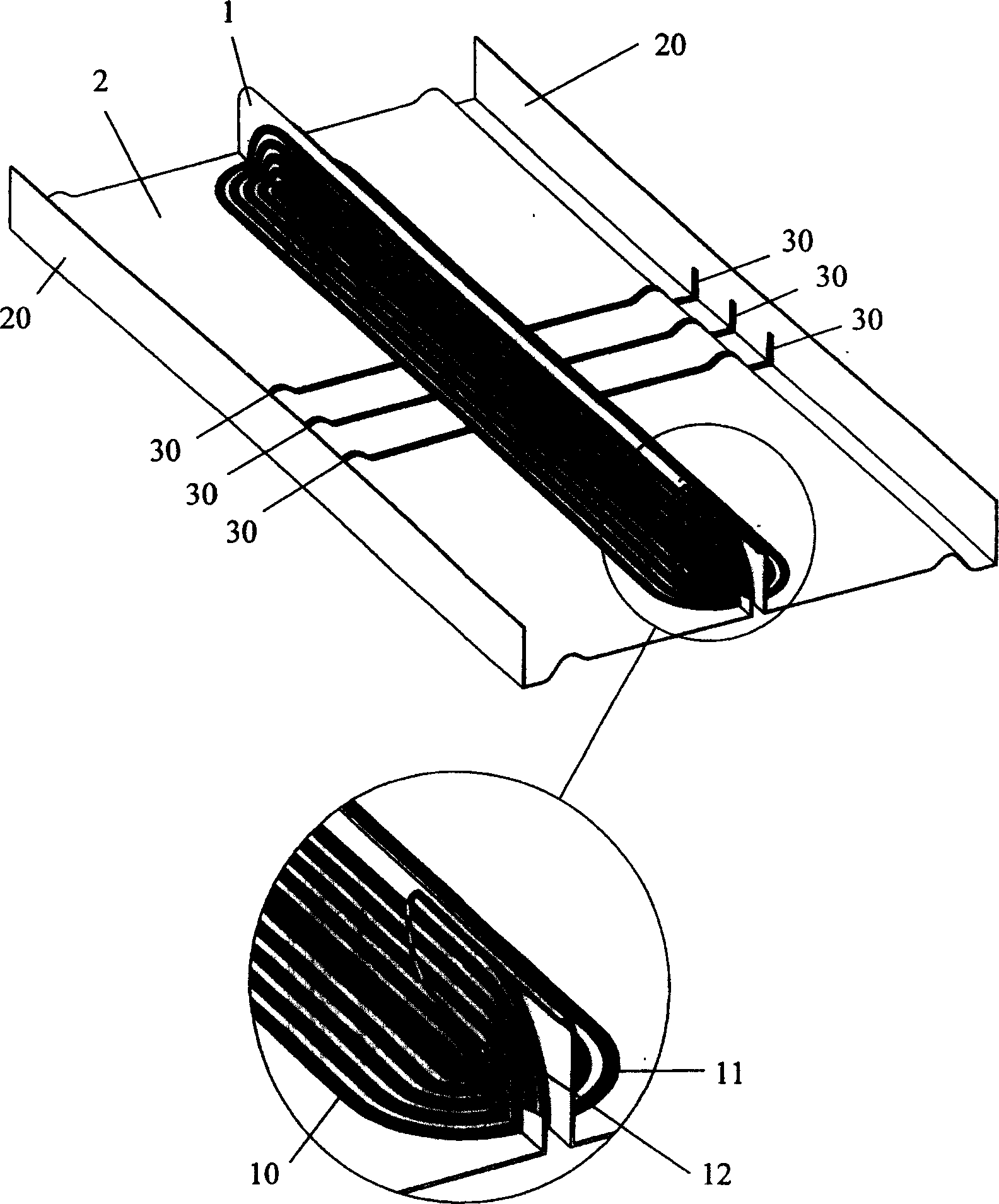

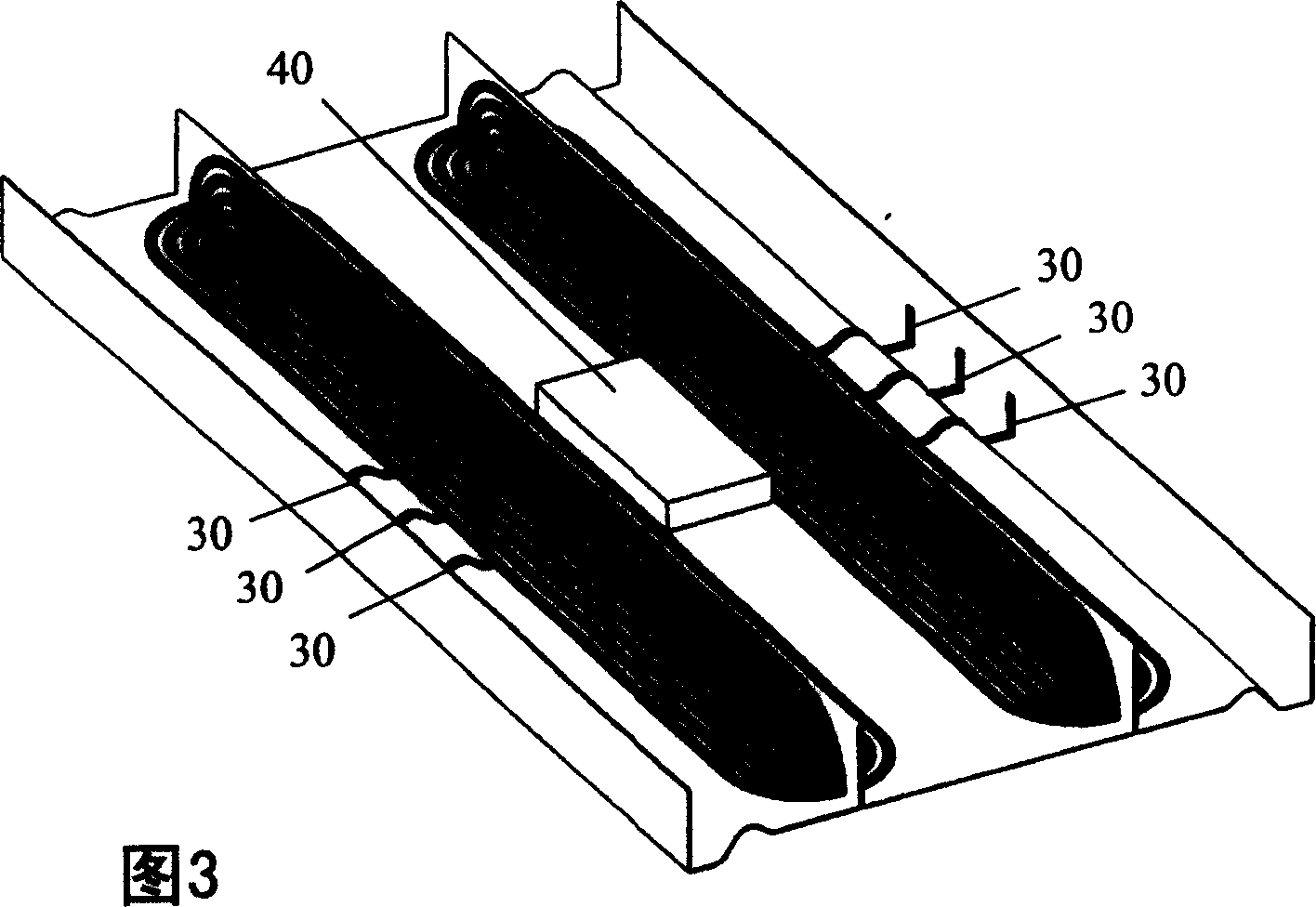

[0032] According to the invention, the coil may be formed from a thin and flexible sheet, such as a flexible printed circuit board, ie a flexible circuit board. Such a thin and flexible sheet will carry the predetermined conductive path thereon, forming a coiled conductive path. As described below, the diaphragm also has conductive portions in its preferred embodiment. Thus, the coil and diaphragm can be made from a single piece of flexible circuit board with corresponding conductive paths, the shape of this single piece can be made: the two long parts of the coil are exposed, and with respect to the rest of the integrated diaphragm / coil at a 90-degree angle.

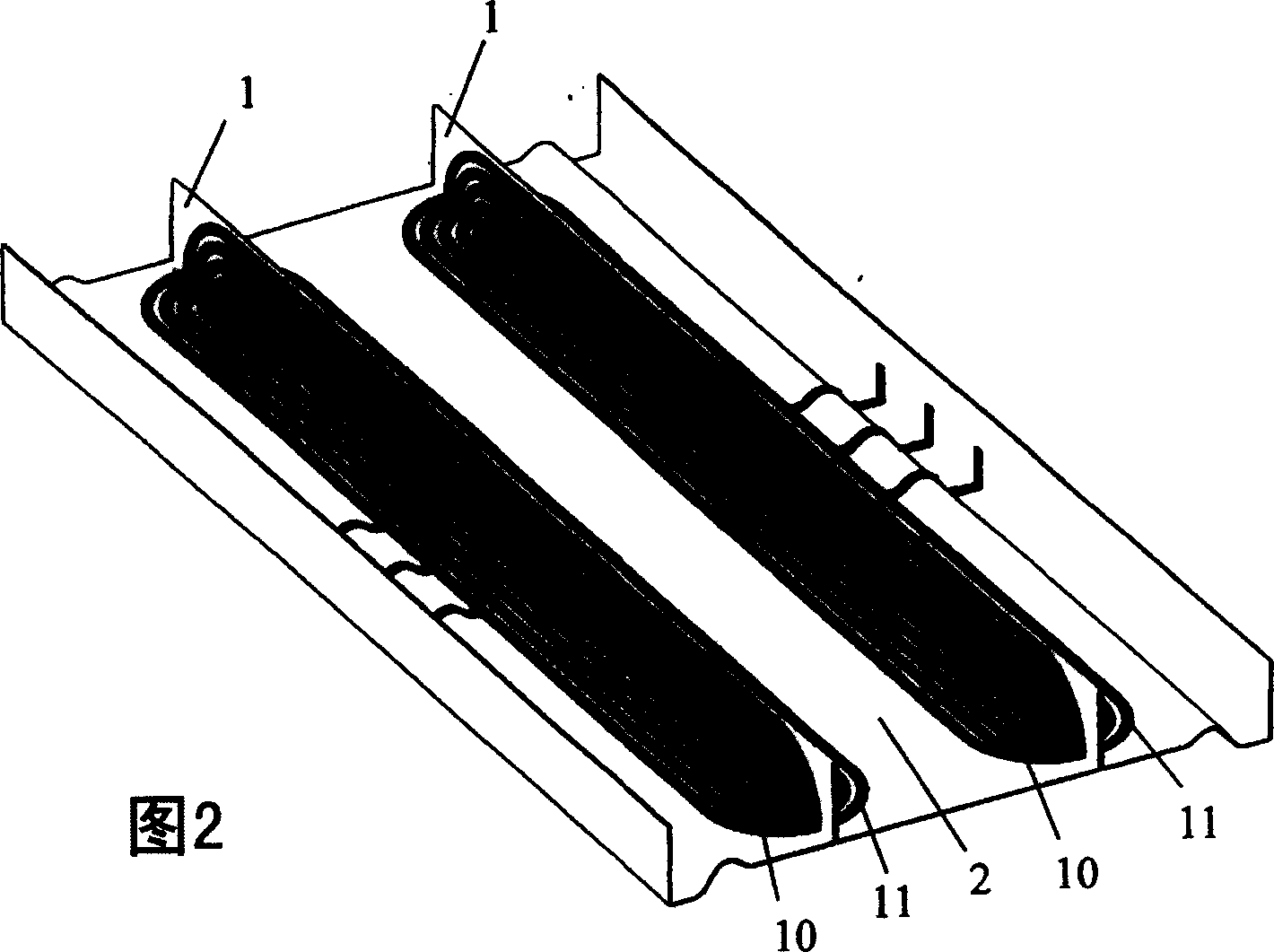

[0033] figure 1 A preferred embodiment of the invention formed from a rectangular double-sided flexible circuit board is shown. figure 1 The diaphragm is shown viewed from the underside of the diaphragm, the side facing the magnetic path when mounted on a sensor. figure 1 The embodiment shown has a spacer portion 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com