Two box shaping and locating method of self setting resin sand for casting

A technology of casting resin and positioning method, which is used in casting molding equipment, mold boxes, manufacturing tools, etc., can solve the problem of inability to meet the production requirements of single-piece and small batches, the defect of casting wrong box has not been improved, and the manufacturing cycle of casting tooling can be solved. long and other problems, to achieve the effect of eliminating wrong type defects, easier control of process conditions, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

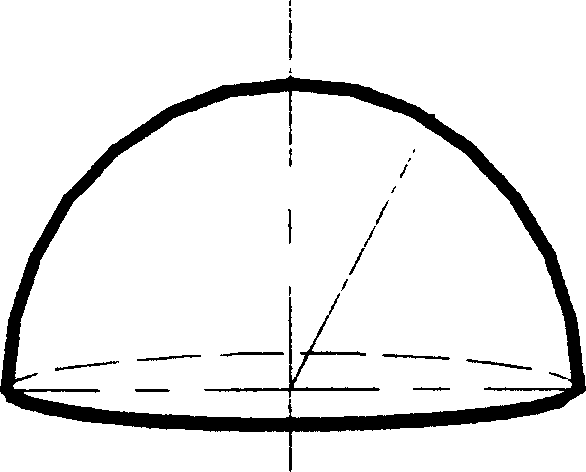

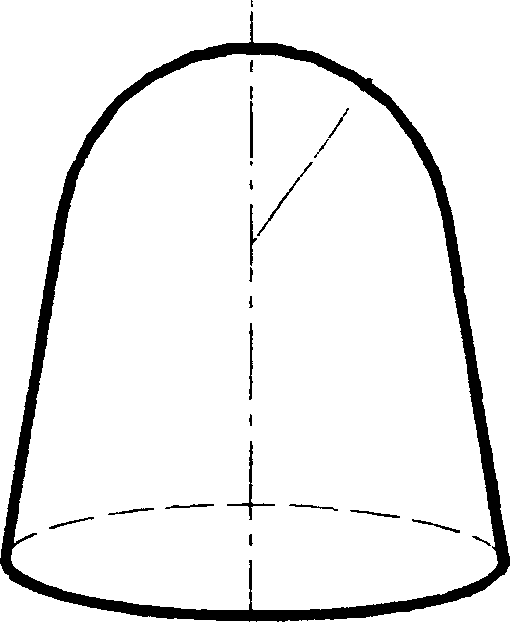

[0015] Positioning blocks with different diameters and heights can be selected according to the shape of the casting. The structure of the positioning block is as follows: figure 1 , figure 2 as shown, figure 1 is a hemispherical positioning block, figure 2 It is a tapered positioning block, you can choose one, follow the steps below:

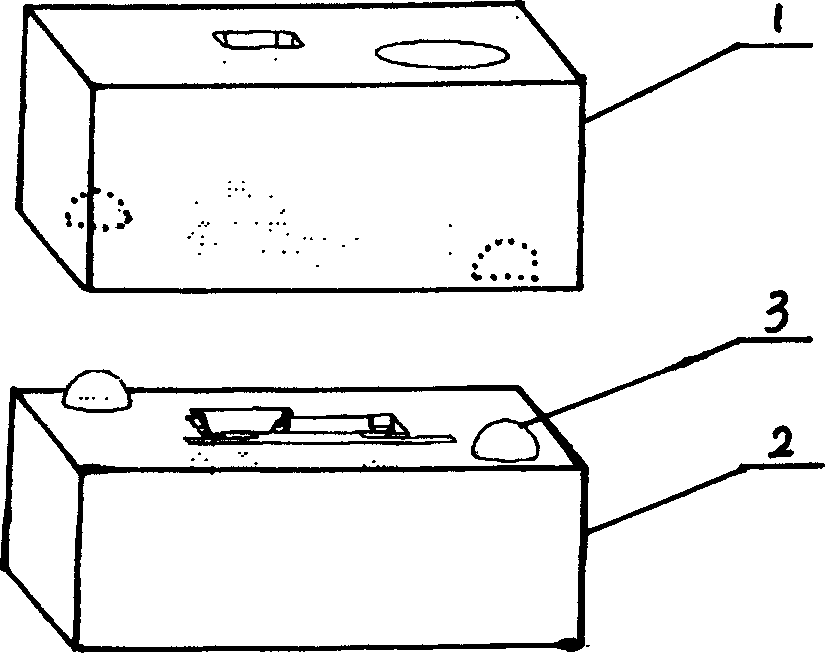

[0016] 1. Make the upper half mold of resin sand: put the casting model and the positioning block on the modeling plate respectively, put on the sand box, generally put the two positioning blocks on the diagonal line in the sand box, fill the resin sand to make Resin sand upper half mold;

[0017] 2. Take out the positioning block: After the sand mold is solidified, turn over the box and take out two independent positioning blocks, which form two concave shapes on the mold;

[0018] 3. Make resin sand lower half mold: Put the sand box on the upper half mold, fill resin sand to make the lower half mold, after the sand mold is solidified, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com