Forming mechanism for high precision optical lens and products produced thereby

An optical lens, high-precision technology, applied in the direction of optical components, other household appliances, household appliances, etc., can solve the problem of lens noise interference, and achieve the effect of simplifying processing procedures, eliminating ghost images, and preventing optical noise interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

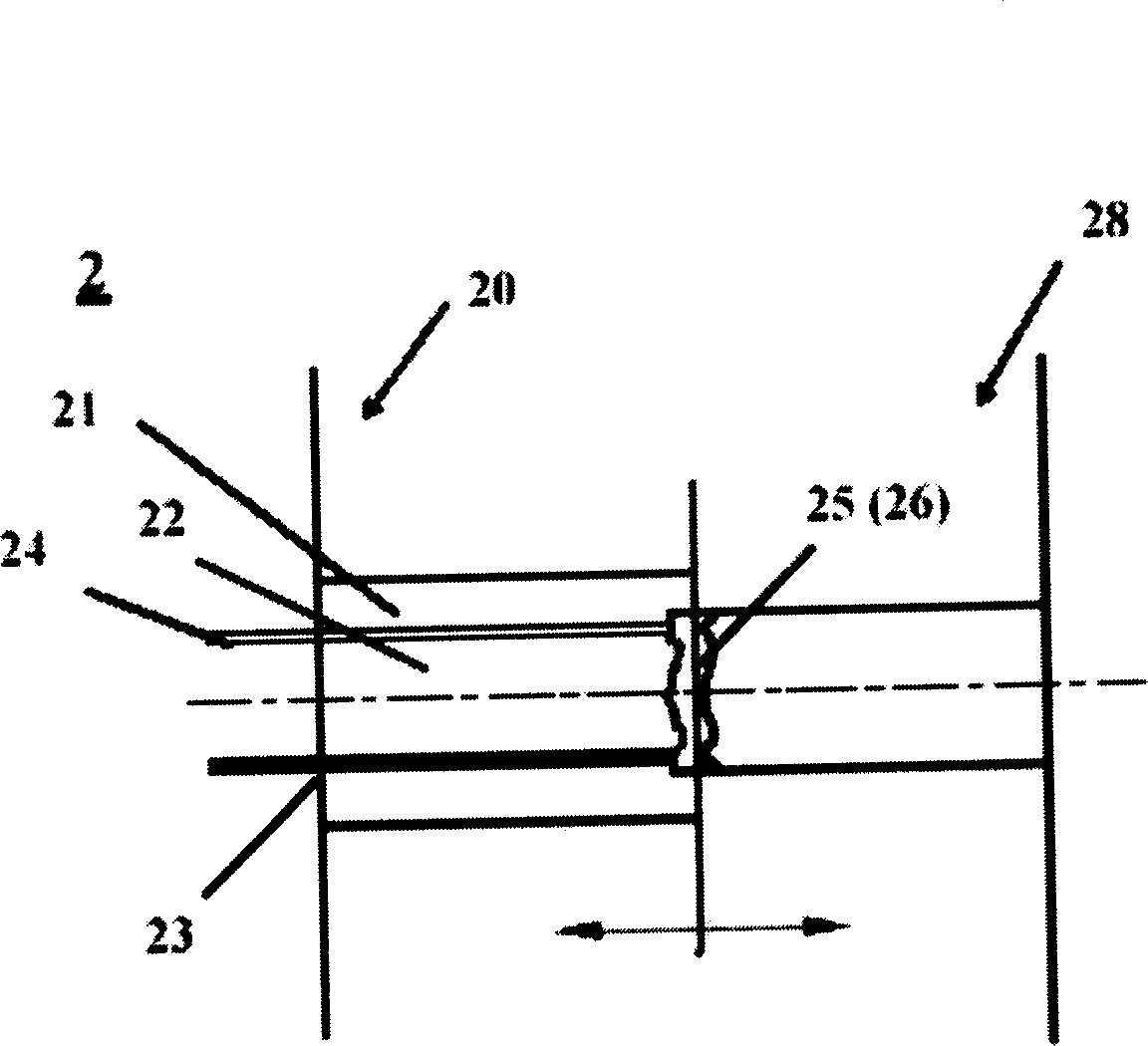

[0031] The molding mechanism and products of the high-precision optical lens of the present invention will be further described in detail in conjunction with the accompanying drawings.

[0032] Such as figure 2 Shown is a schematic cross-sectional view of a high-precision optical lens forming mechanism 2 of the present invention. The molding mechanism 2 includes a first split mold 20 and a second split mold 28 matched therewith. After the first split mold 20 and the second split mold 28 are molded together, a mold cavity 25 for molding an optical lens 26 can be formed. Wherein the first parting mold 20 can be preset as the movable parting mold 20, and the second parting mold 28 can be preset as the fixed parting mold 28, and the movable parting mold 20 can be separated from the fixed parting mold 28 when the mold is opened.

[0033] The most important feature of the present invention that is different from the prior art is that: during demoulding, the first parting mold 20 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com