Hinge for collapsible flatrack

A technology of hinges and webs, applied in the directions of folding panels, packaging, transportation and packaging, etc., which can solve the problems of heavy manufacturing costs of solid panel hinges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

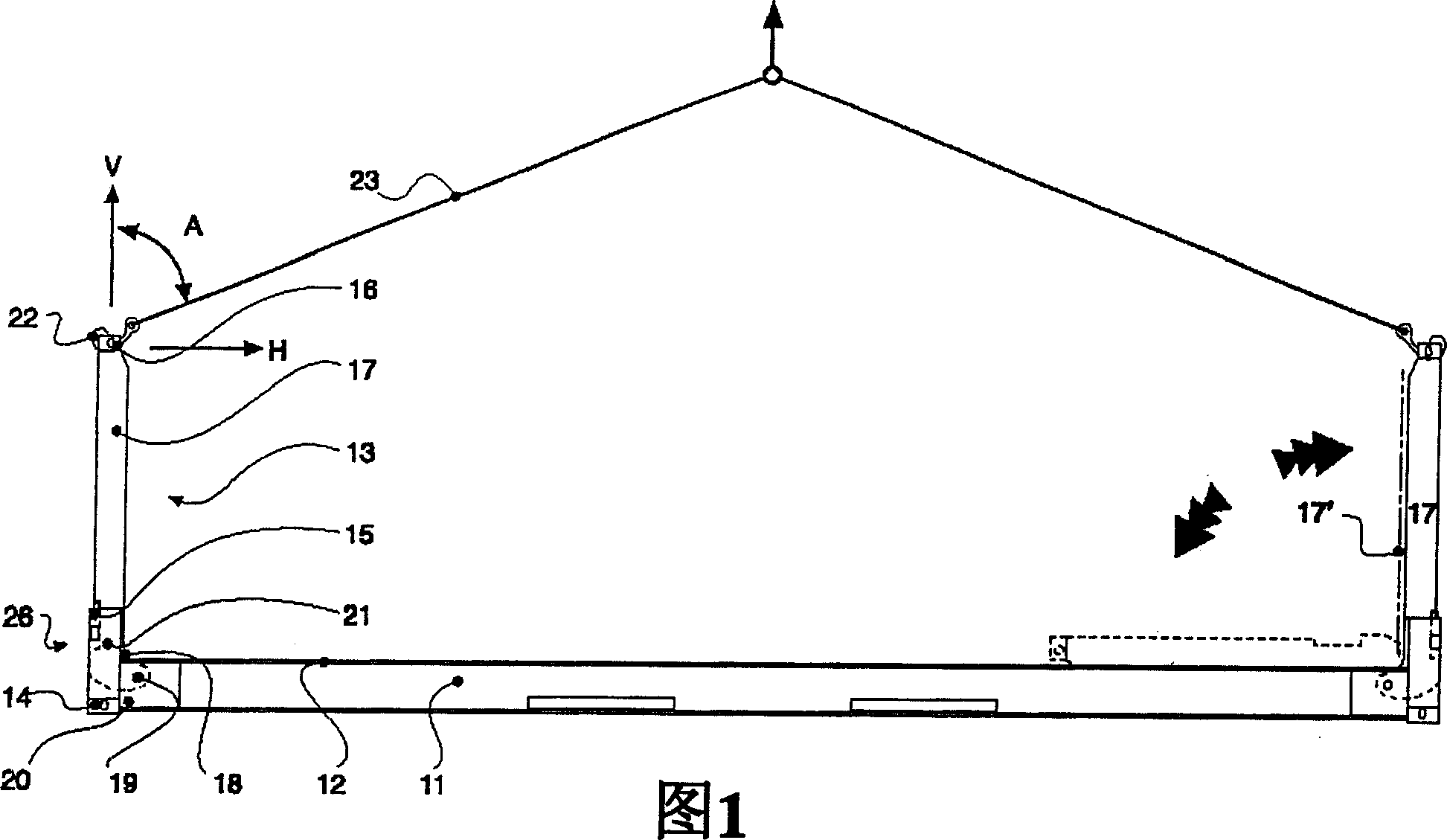

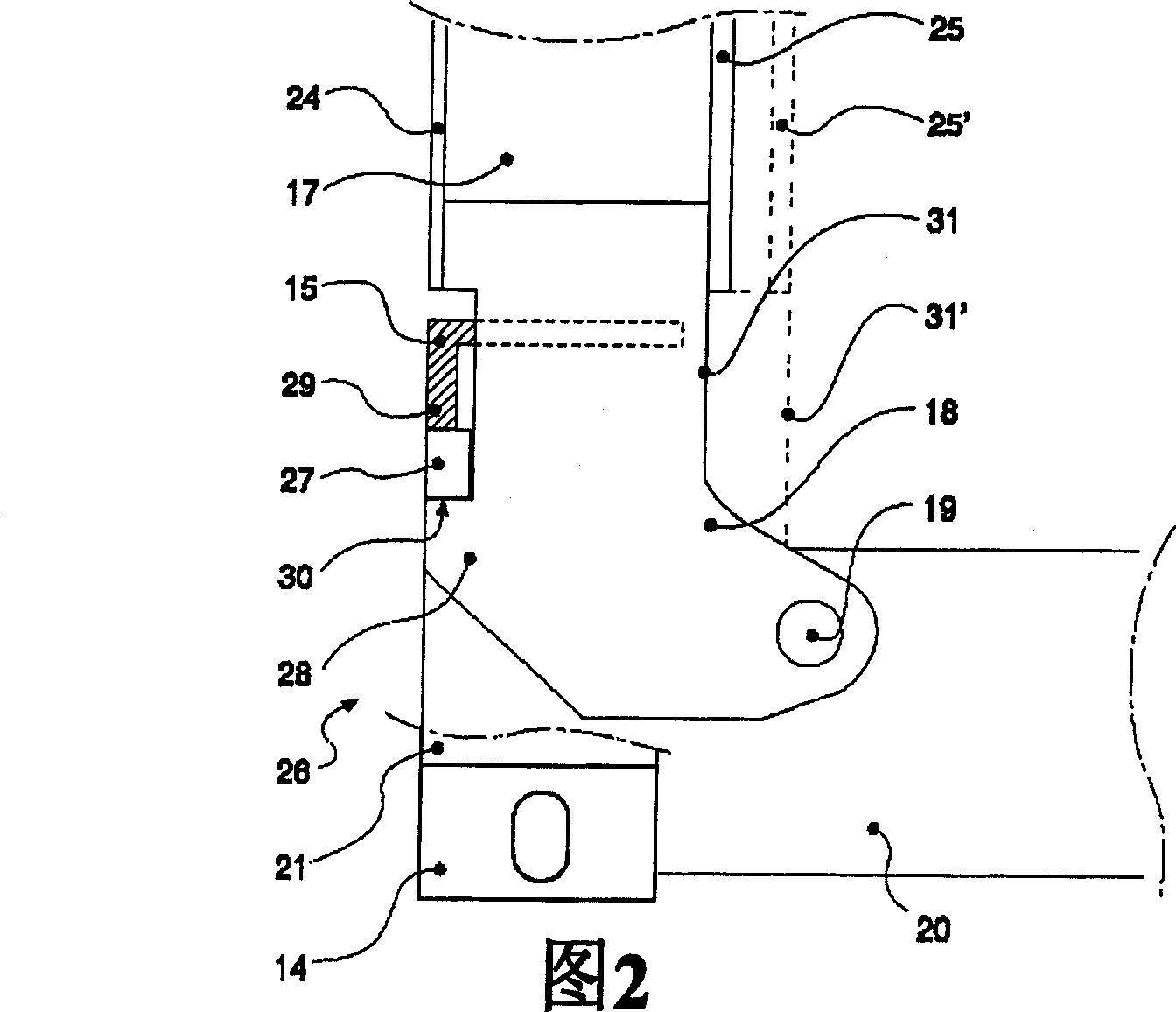

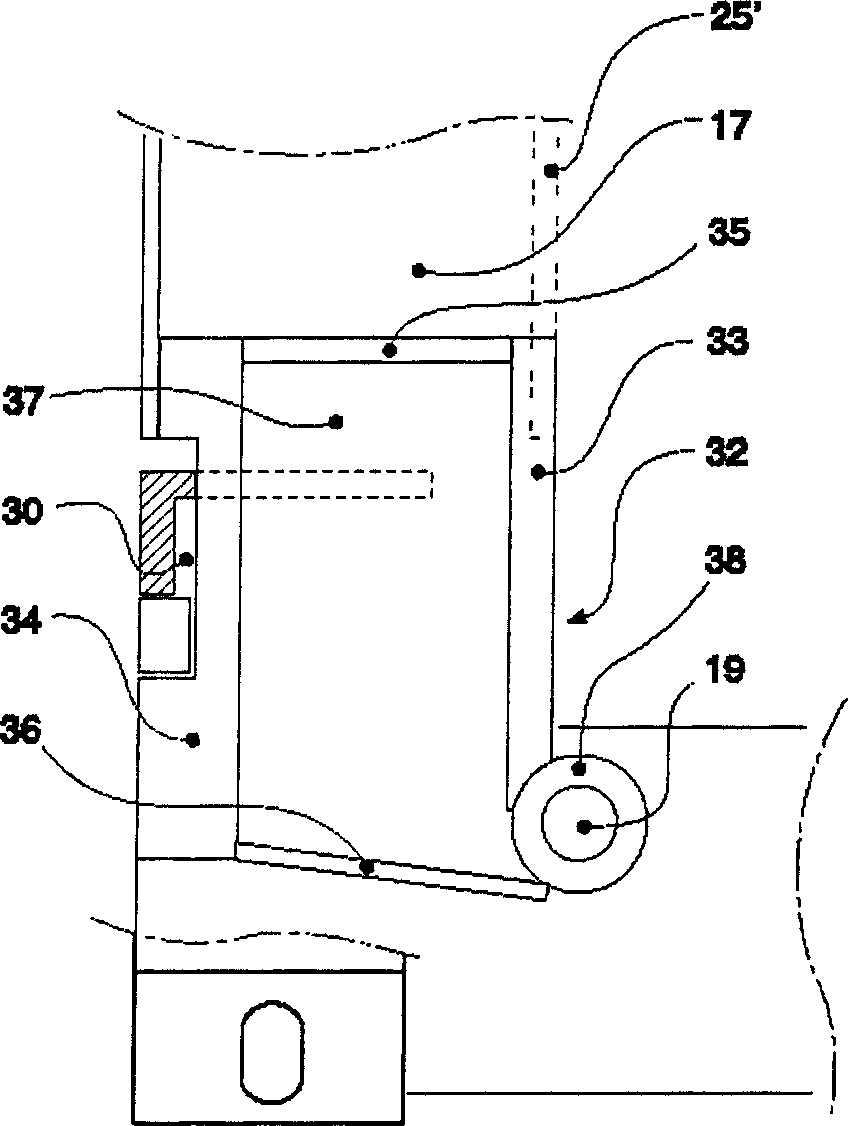

[0074]Referring to the drawings, a collapsible container pallet 11 has a platform base with a floor surface 12 surrounded between opposite ends by folded end walls 13 supported between hinged corner posts 17 .

[0075] At each bottom corner there is a corner fitting 14 and a base 20 into which a hinge interior 18 clamped by a pivot pin 19 is mounted.

[0076] The hinge outer 21 has a top (plate) fitting 15 through which the hinge inner 18 passes when the associated corner strut 17 is erected in a vertical position.

[0077] At the top of each corner post 17 is a top clip fitting 16 to which a hook 22 is attached, the end of which is attached to one end of a suspension sling 23 .

[0078] The opposite sides of the sling 23 are inclined at an angle "A" to the vertical "V".

[0079] If the container panel 11 is lifted by the sling 23, a horizontal component "H" is created at the top of the fitting 16.

[0080] This imposes a considerable bending motion on the inner 18 and oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com