Stress self-balancing and deviation rectification equipment for column system in use for push constructing bridge floor structure

A technology of rectifying device and jacking construction, which is used in bridges, bridge construction, erection/assembly of bridges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

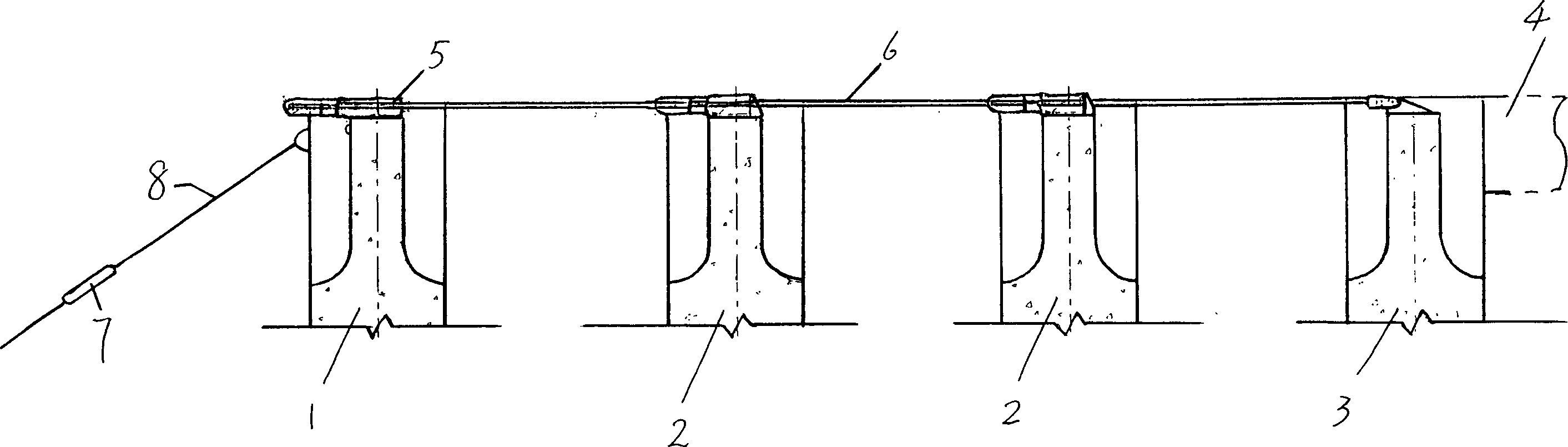

[0006] Assemble the bridge deck structure on the tire frame 4 on the side of the designed installation position of the bridge deck structure. All on the same straight line and loosen the anchorage of each through-type jack 5, pass the steel strand 6 through each through-type jack 5, and one end of the steel strand 6 is fixed on the end column 3 fixedly connected with the tire frame 4 At the top, after the steel strands 6 are arranged into a straight line, the other end is clamped by the anchorage of the through-hole jack 5 on the top of the head column 1, and then the cable wind rope 8 is fixedly connected to the top of the head column 1. The other end is connected in series with the turnbuckle 7 and anchored to the ground; after checking and confirming that the anchorage of the through-type jack 5 on each middle column 2 is in a loose state, adjust the plunger of the through-type jack 5 on the head column 1 to extend out The length is to apply a preload to the steel strand 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com