Visible light part concealing suit

A stealth suit and visible light technology, applied in clothing, clothing, protective clothing, etc., can solve the problems of not being able to stealth in time, decreasing stealth effect, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

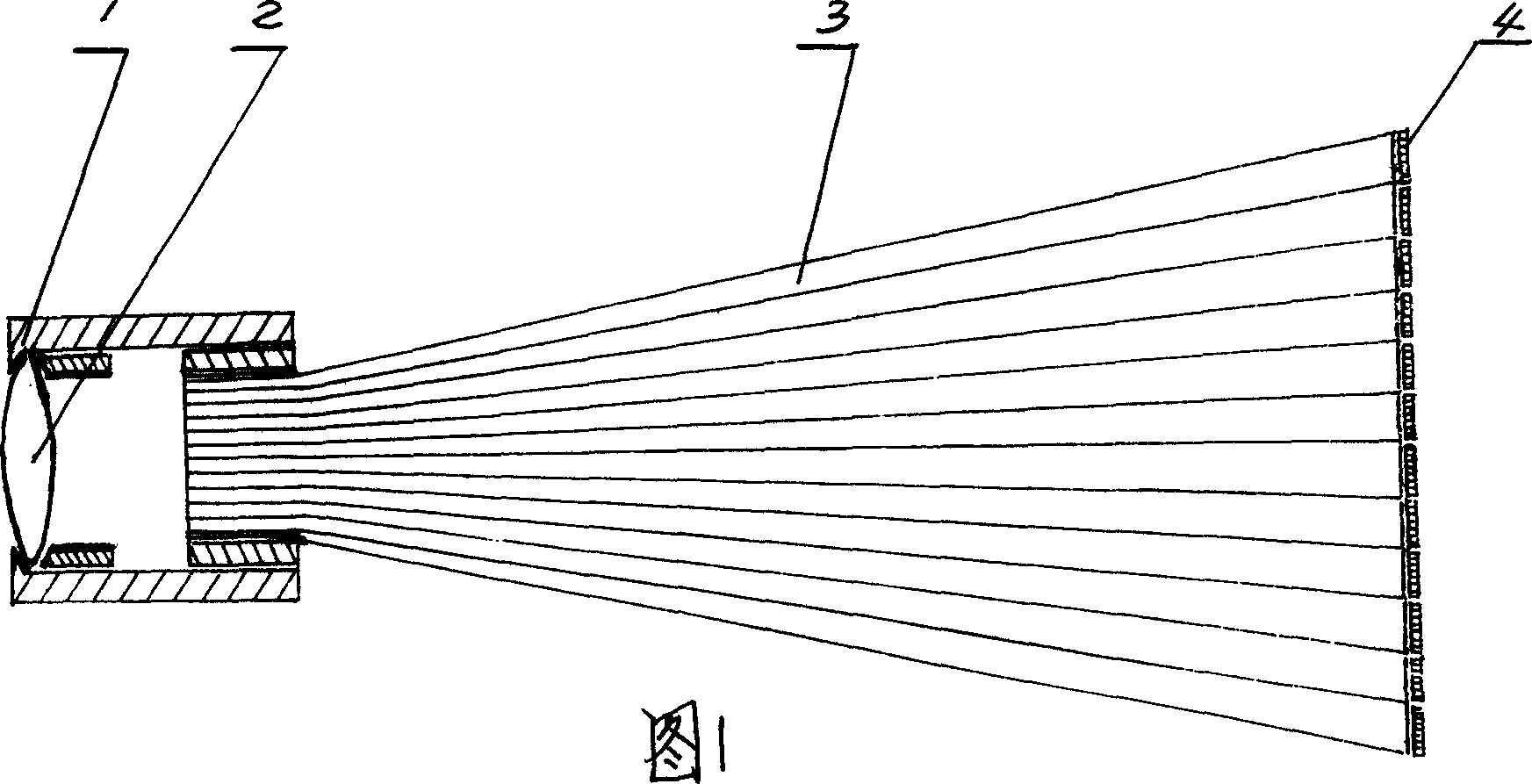

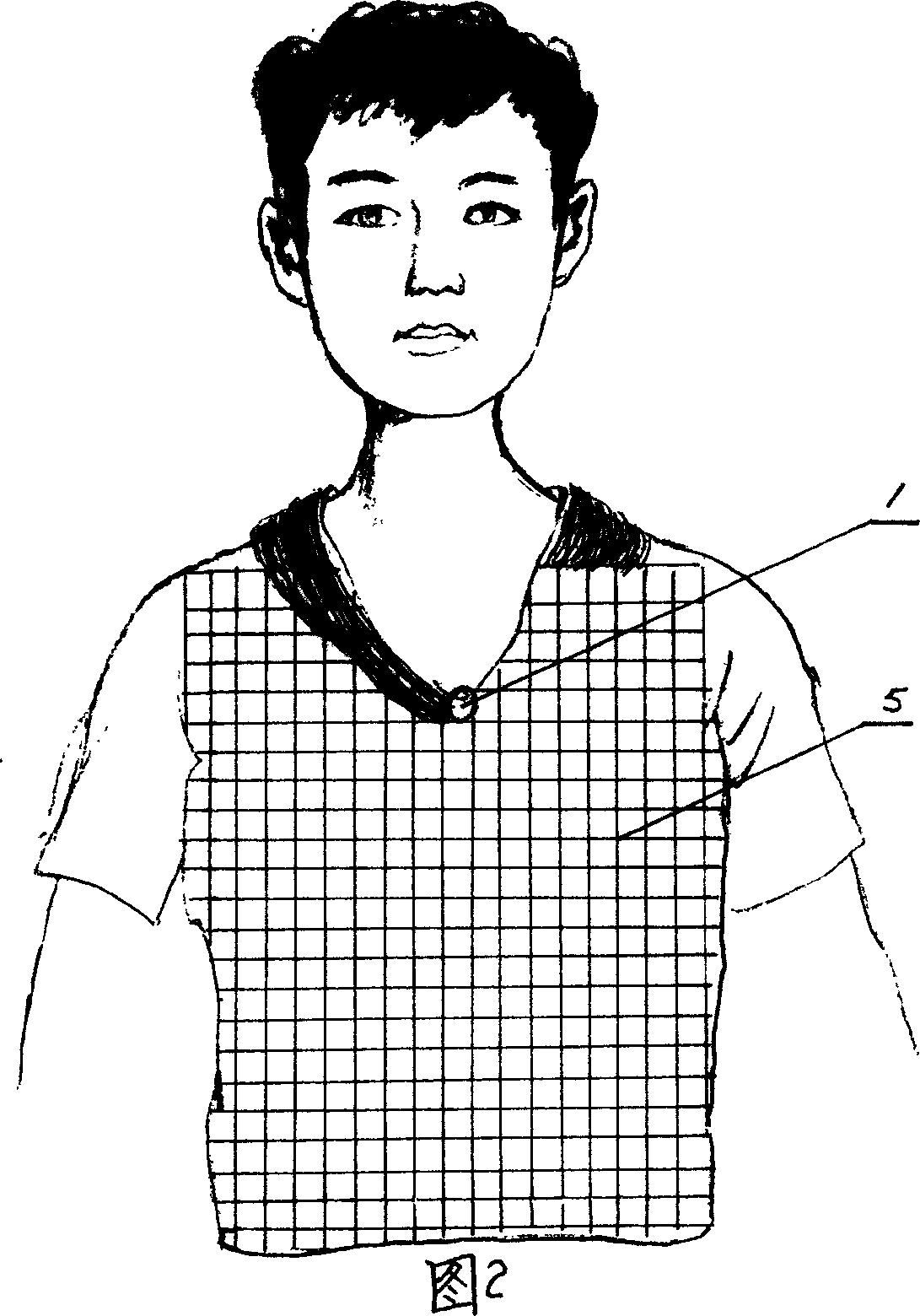

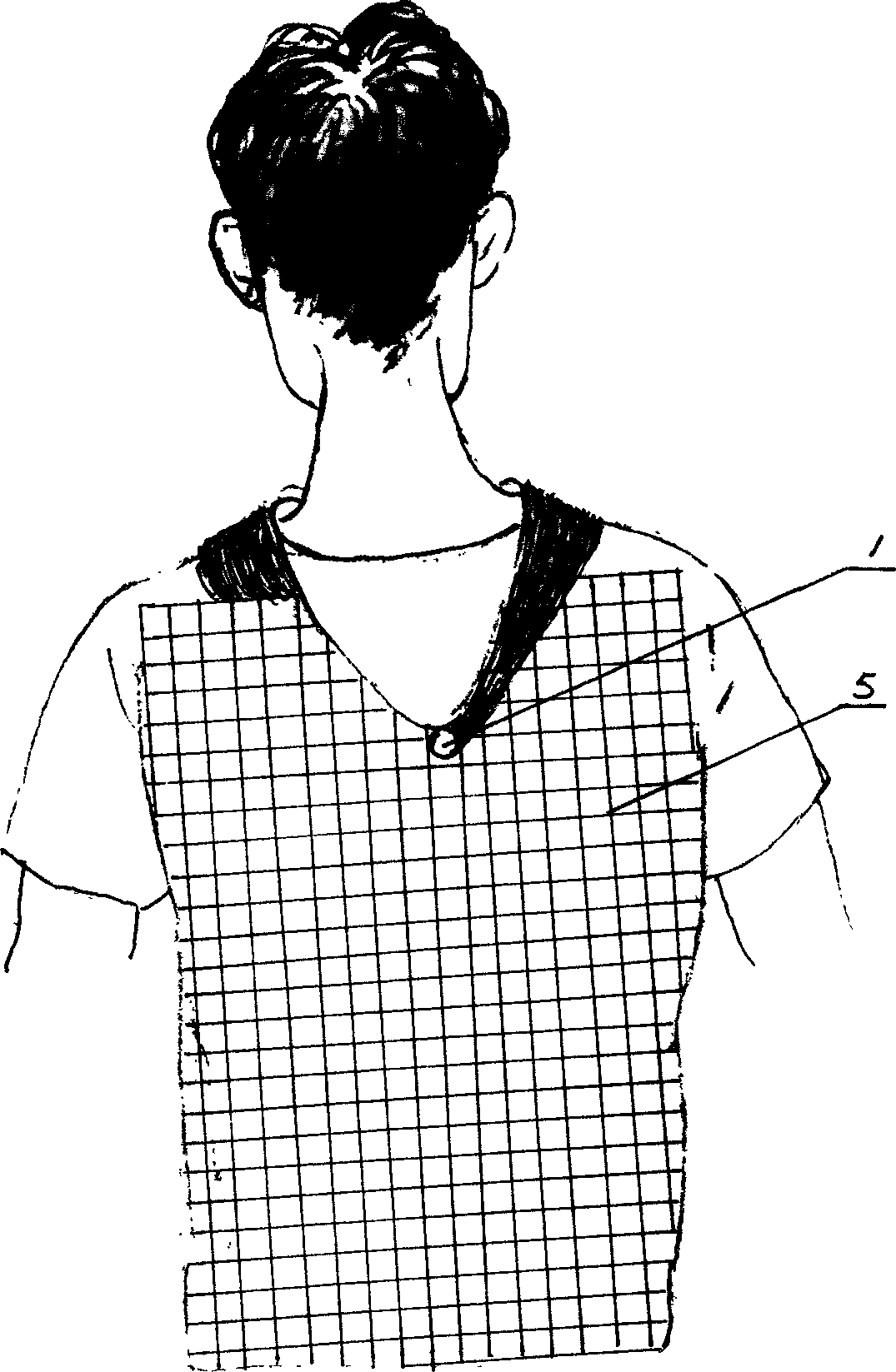

[0005] The front portion and the rear portion of the partial stealth suit of the present invention are respectively equipped with an objective lens 1, a cone-shaped optical fiber filament 3, and its small diameter end is placed in the housing of the objective lens 1 at the stealth suit front portion, and its end face is connected with the camera focusing lens 2 Relatively, its large-diameter end is placed on the grid at the rear of the stealth suit 5, and the position arrangement of the large-diameter end of each optical fiber is the same as that of the small-diameter end. The small-diameter end of another bundle of optical fiber filaments is placed in the casing of the objective lens at the rear of the stealth suit. The position arrangement of the end is the same as that of the small diameter end. The end face of the optical fiber filament at the front and back of the stealth suit is provided with an anti-reflection film 4, which can be made from any of the following material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com