Induced cracking process for crack resistant performance test of cement base material and apparatus thereof

A cement-based material, anti-crack performance technology, applied in the direction of measuring devices, analysis materials, material inspection products, etc., can solve the problems of long test time, inaccurate test results, large randomness, etc., to achieve simple use and shorten observation time, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

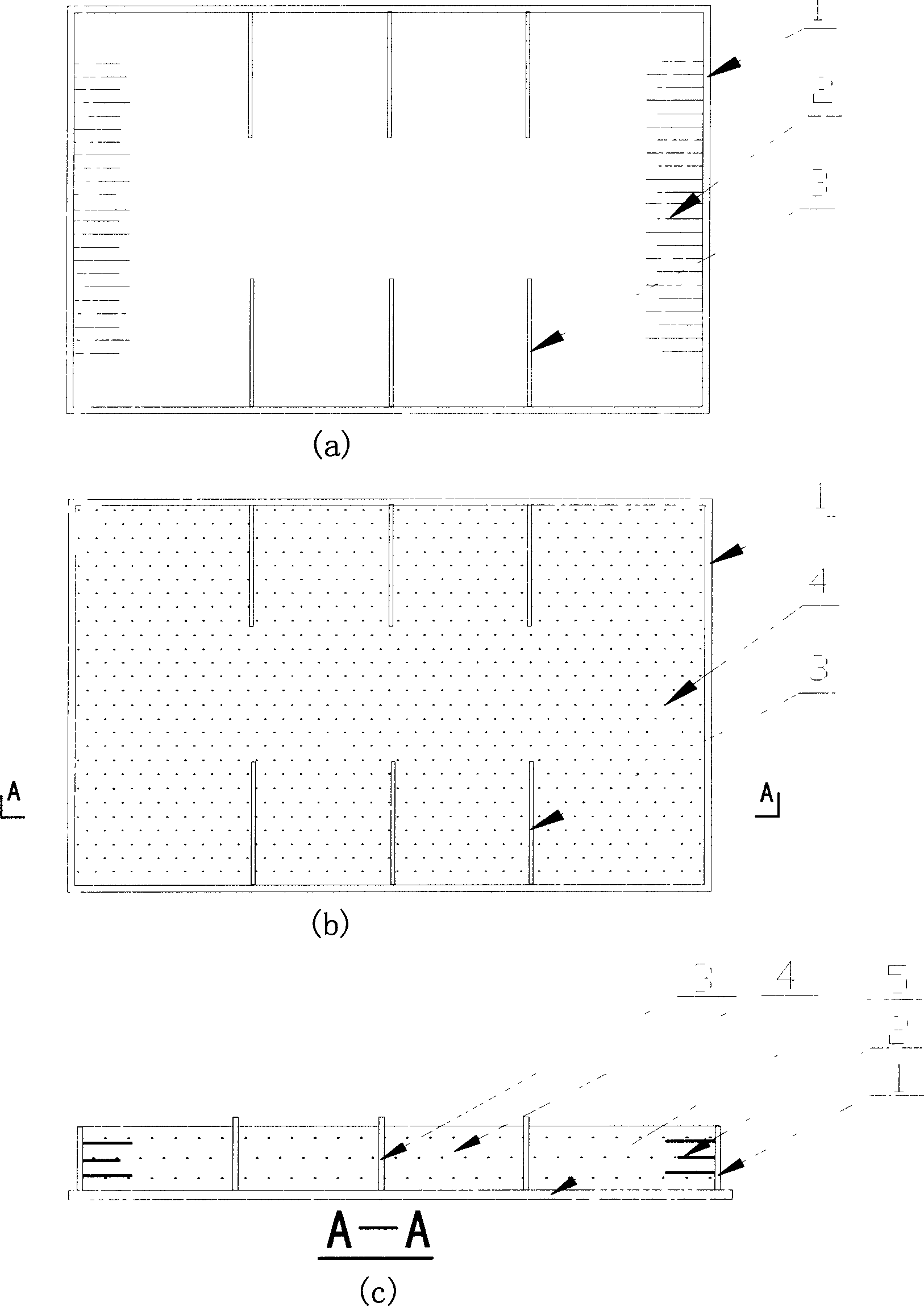

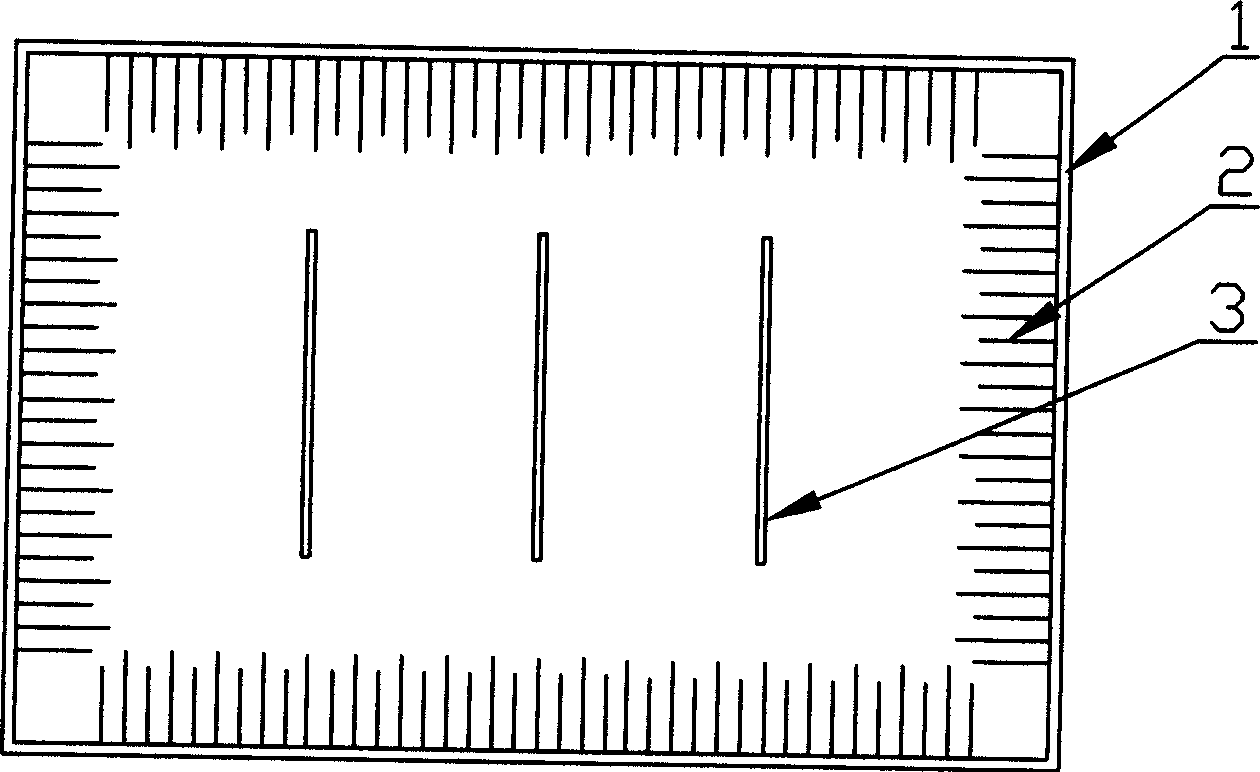

[0023] Such as figure 1 Shown: According to the size of the rectangular frame body 1 and the shrinkage of the cement-based material, in the rectangular frame body 1 constrained in one direction, set 1 to 10 pairs along the free side perpendicular to the rectangular frame body 1 with a length of 1 / 10~ 2 / 5 Frame body 1 constrains the partition board 3 with side length, and evenly divides the frame side of frame body 1, thereby reducing the cross-sectional area of the corresponding section. When the cement-based material shrinks, the stress generated at this section is greater than that of other sections. section, thereby accelerating the generation of cracks and guiding cracks to be generated in this section. The position and the number of cracks that may appear are relatively determined, and the cracks appear early, develop quickly, and have a large width, which is easy to observe, with short observation time and high accuracy.

Embodiment 2

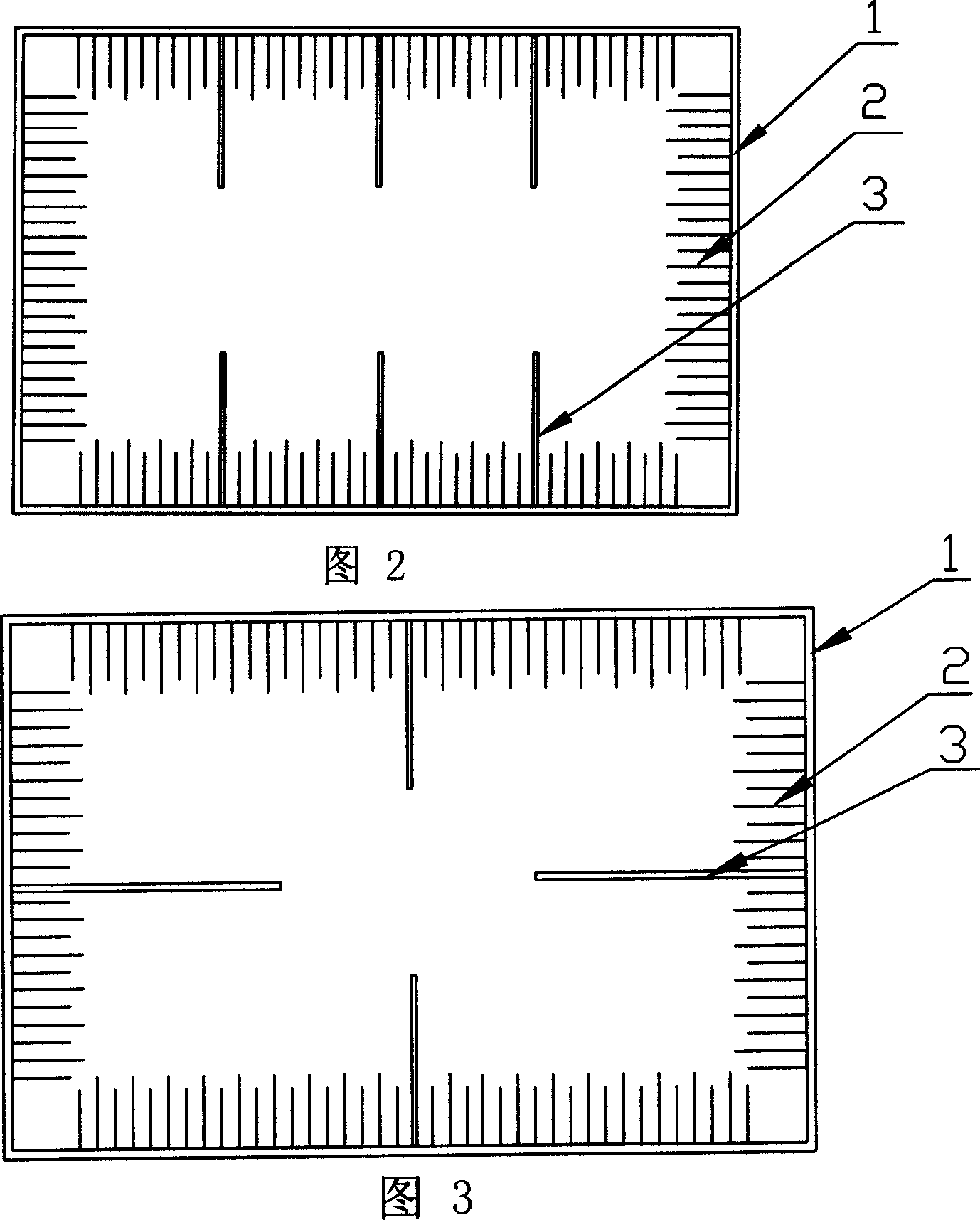

[0025] As shown in Figure 2, according to the size of the frame body 1 and the size of the shrinkage of the cement-based material, 1 to 10 pairs of partitions 3 are arranged in the rectangular frame body 1 with two-way constraints along the long frame side perpendicular to the rectangular frame body 1, The length of the partition 3 is 1 / 10 to 2 / 5 of the length of the short side of the rectangular frame 1, and the long side of the frame 1 is evenly divided into equal parts, thereby reducing the cross-sectional area of the corresponding section. When the cement-based material shrinks, the The stress generated at this section is greater than that at other sections, thereby accelerating the generation of cracks and guiding cracks to be generated at this section.

Embodiment 3

[0027] As shown in Figure 3: in the rectangular frame body 1 with two-way constraints, a partition plate 3 is arranged in the middle of the four frame sides 1 along the frame side perpendicular to the frame body 1, and the length of the partition plate 3 is parallel to the frame body 1 / 10 to 2 / 5 of the frame side length of 1, thereby reducing the cross-sectional area of the corresponding section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com