Semi-underground tunnel type methane autoclave

A technology of underground tunnels and reactors, applied in the field of biogas reactors, can solve problems such as immature gas production solutions, unstable biogas quality, and complex structures, and achieve the effects of simple and time-saving installation, light operation, and perfect structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

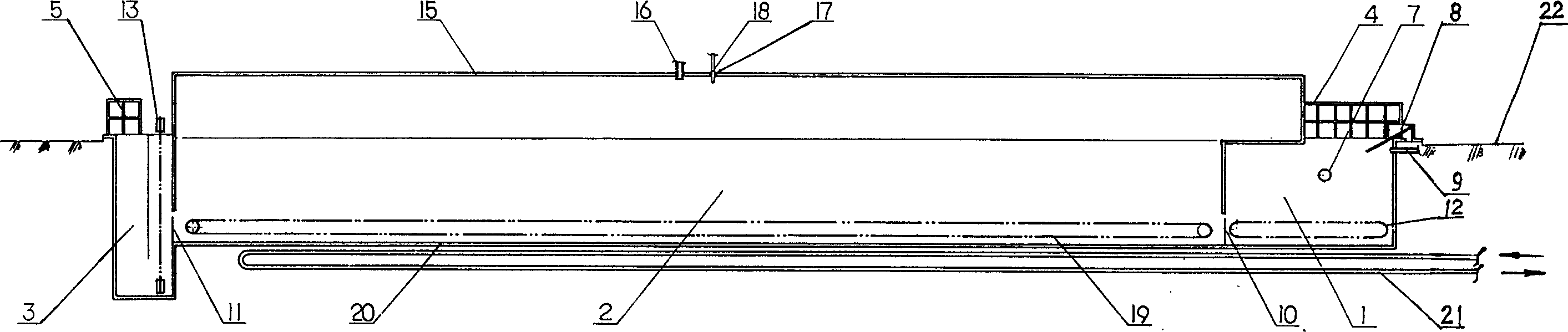

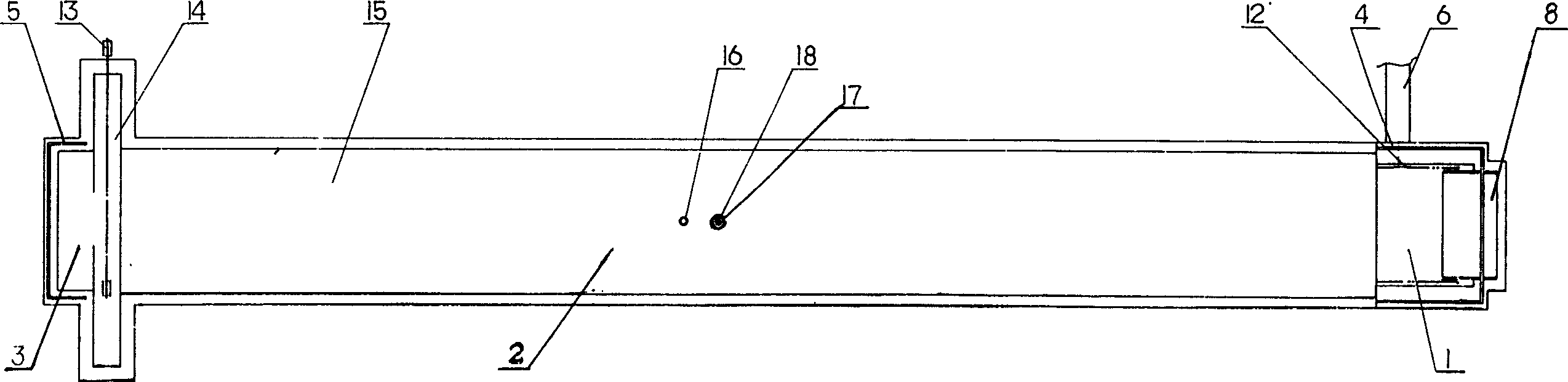

[0010] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

[0011] see figure 1 , figure 2 , The present invention includes a material preparation pool 1, a gas production pool 2 and a material discharge pool 3. The gas production pool 2 is located in the center of the reactor, keeping it relatively closed; the material preparation pool 1 and the discharge pool 3 are respectively arranged on both sides of the gas production pool 2; along the periphery of the ground 22 of the material preparation pool 1 and the discharge pool 3, there are front , Rear guardrail 4, 5, to prevent personal accidents, to ensure the safety of operators. The outside of the material preparation pool 1 is provided with a continuous water tank 6 and communicates with the material preparation pool 1 through the water supply hole 7. The side of the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com