Metallic beverage can end with improved chuck wall and countersink

A chuck, end wall technology applied in the field of metal beverage can end closures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

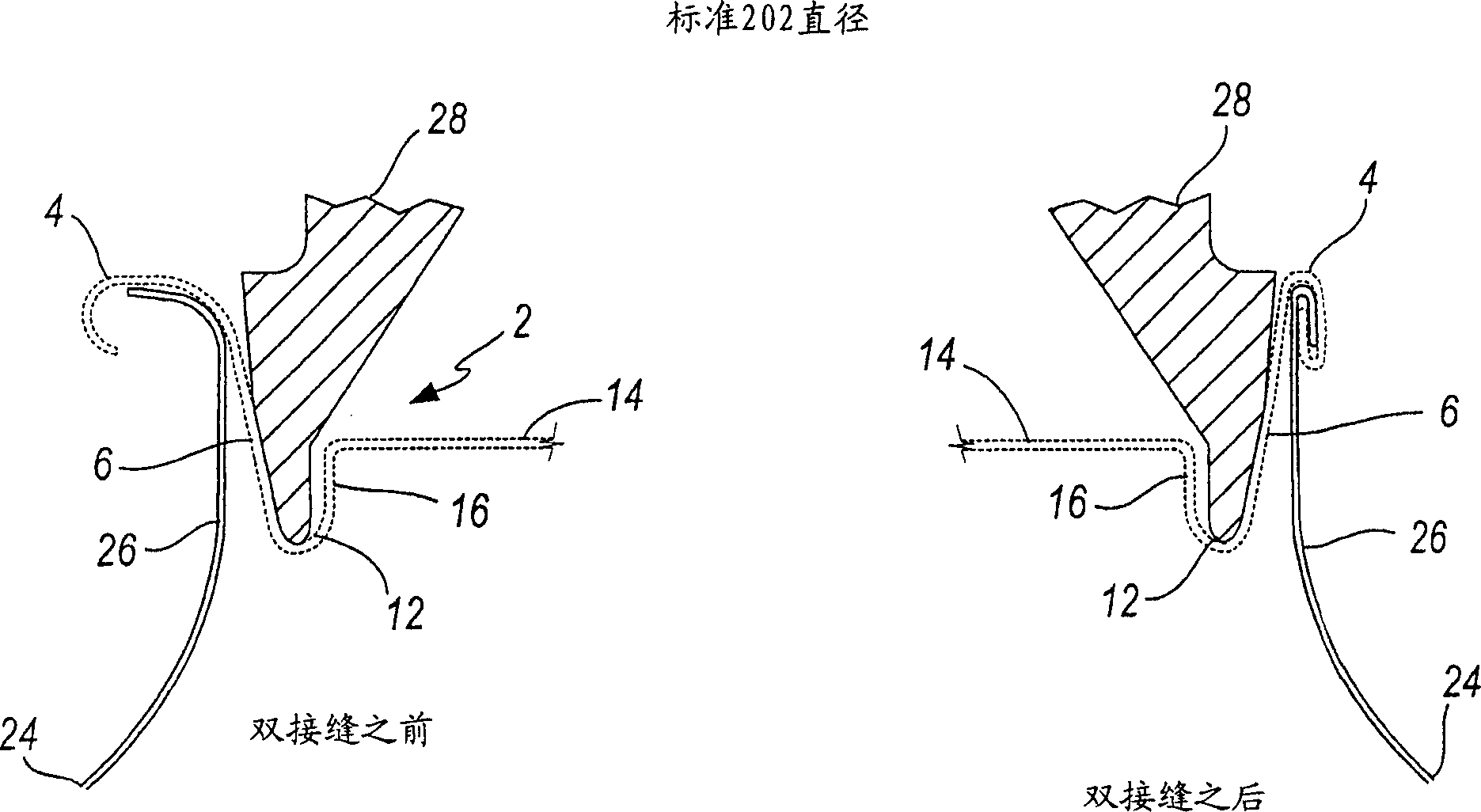

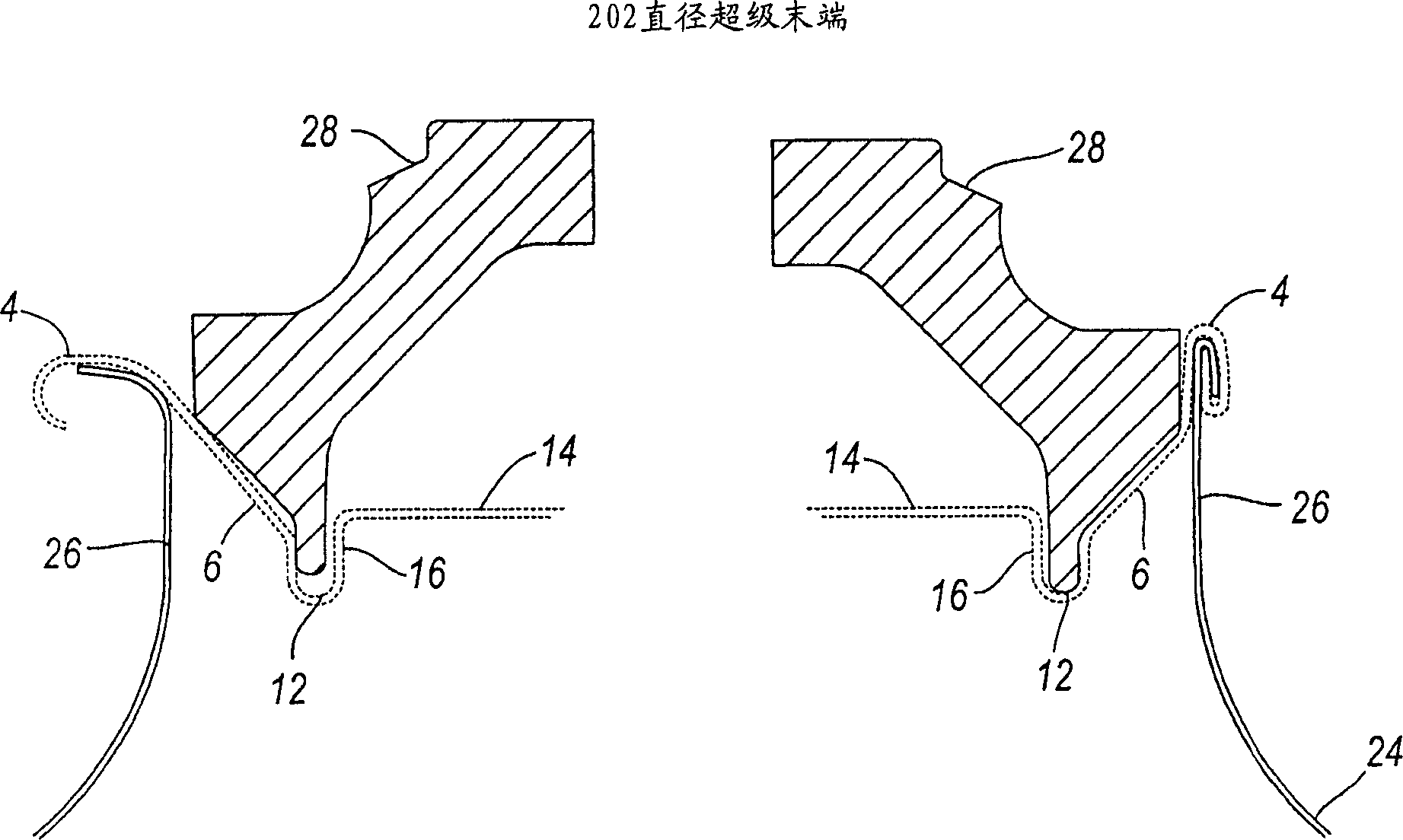

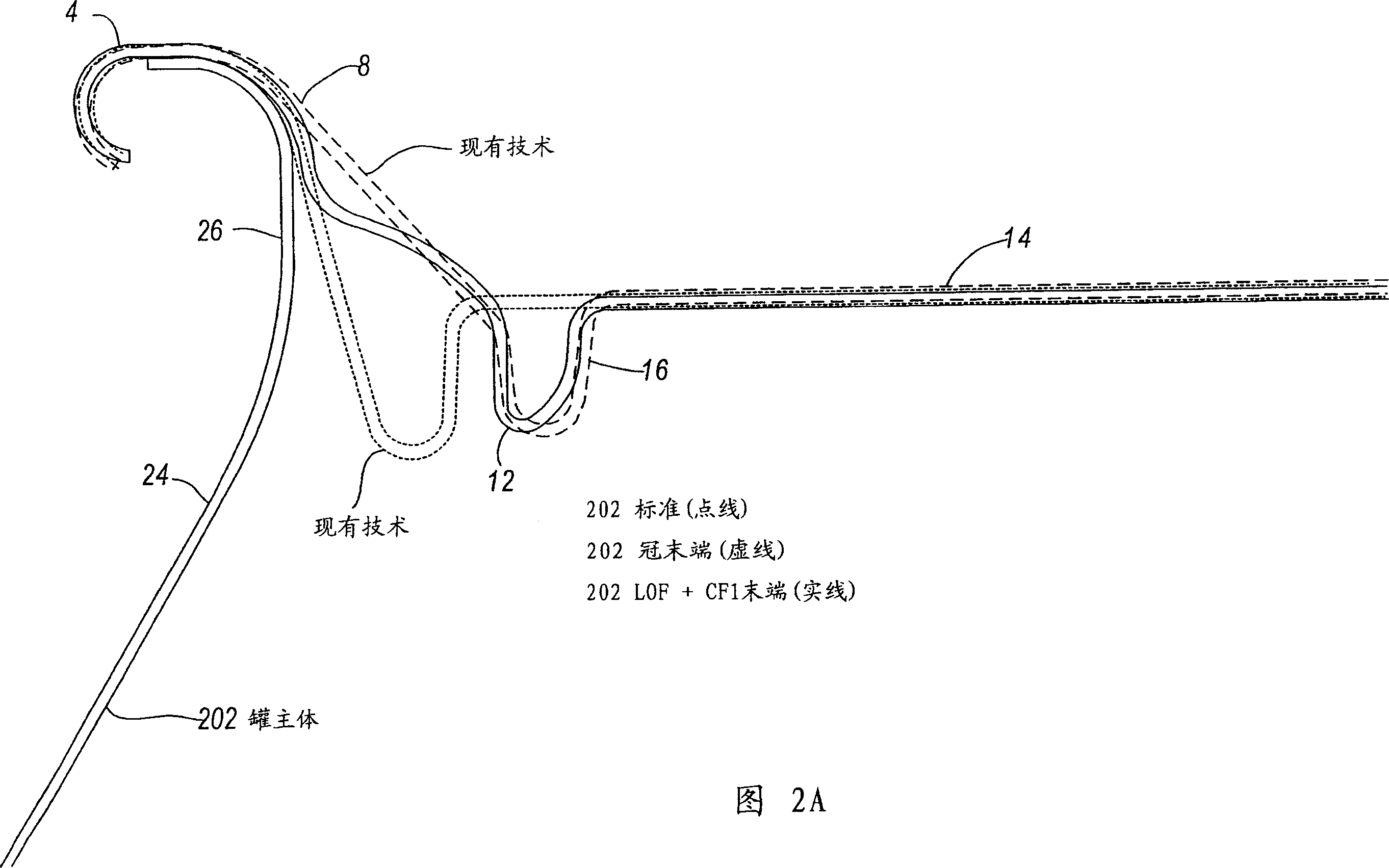

[0040] Referring now to FIGS. 1-7B , there are provided cross-sectional front views of prior art beverage can ends ( FIGS. 1-2A ) and various embodiments of the present invention ( FIGS. 3-7B ). More particularly, the metal beverage can 2 described herein generally consists of an annular end wall 4 , a chuck wall 6 , a countersink 12 , a center panel 14 , and an inner panel wall 16 interconnecting the center panel 14 to the countersink 12 . The chuck wall 6 may additionally include an upper chuck wall 8 and a lower chuck wall 10, which in some embodiments may have a first radius of curvature Rc1 and a second radius of curvature Rc2, respectively. In some embodiments, the inner panel wall 16 may additionally include an inner panel wall upper end 18 and an inner panel wall lower end 20 . Furthermore, the top of the annular end wall 4 is defined by what is typically called a crown 22 in beverage can art.

[0041] Here the chuck wall angle θ 1 is defined as the angle that the ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com