Process for manufacturing nanocrystal double wrapping edges by using roller knifes

A nanocrystalline, double-wrapping technology, applied in the directions of lamination auxiliary operation, lamination device, lamination, etc., can solve the problems of complex production process, poor product appearance quality, high production cost, and achieve improved production efficiency and high-quality appearance. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

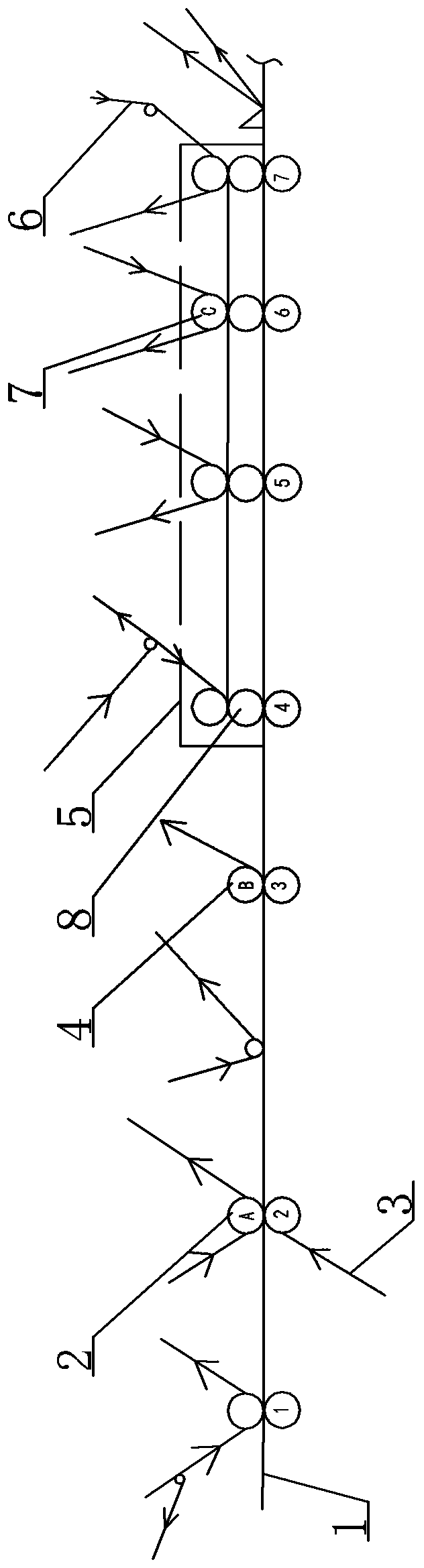

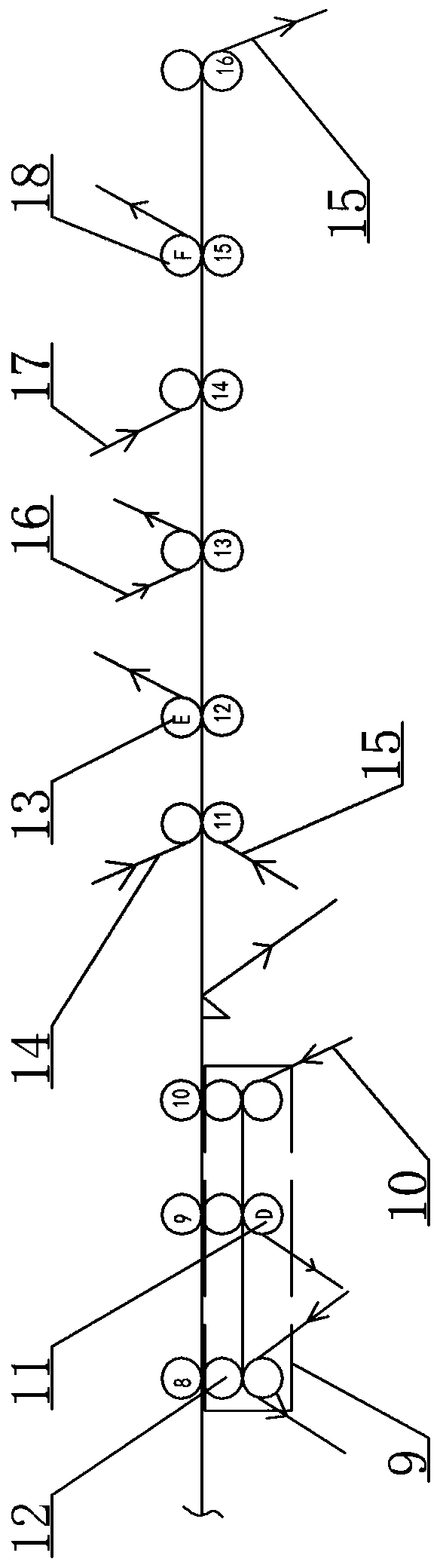

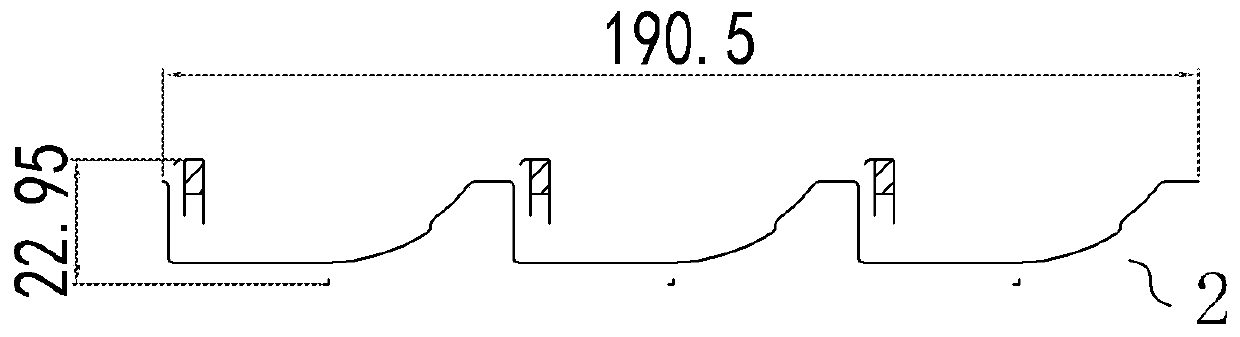

[0023] A kind of technology that utilizes roller knife to make nanocrystalline double wrapping, see Figure 1-Figure 9 : It uses the first roller knife to cut the nanocrystalline coil into shape, and then forms the first thermal conductive film frame above the glue-free area on the upper surface during the process of conveying the nanocrystalline semi-finished product along the roller table to complete the composite , and then the nanocrystalline semi-finished product is transported forward again, forming a second thermally conductive film corresponding to the area under the adhesive layer area on the lower surface, and completing the compounding, and then the composite bottom is finally coated with a release film by transporting forward, and Die-cut the nanocrystalline finished release film cover film that forms the upper layer, and then roll it up.

[0024] The specific process flow is as follows: the nanocrystalline coil 1 is sent into the production line through the convey...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tackiness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com