Beverage can end with outwardly extending reinforcing bead

A beverage can and can end technology, which is applied in the field of metal beverage can ends to achieve the effect of eliminating stamping or pressure processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

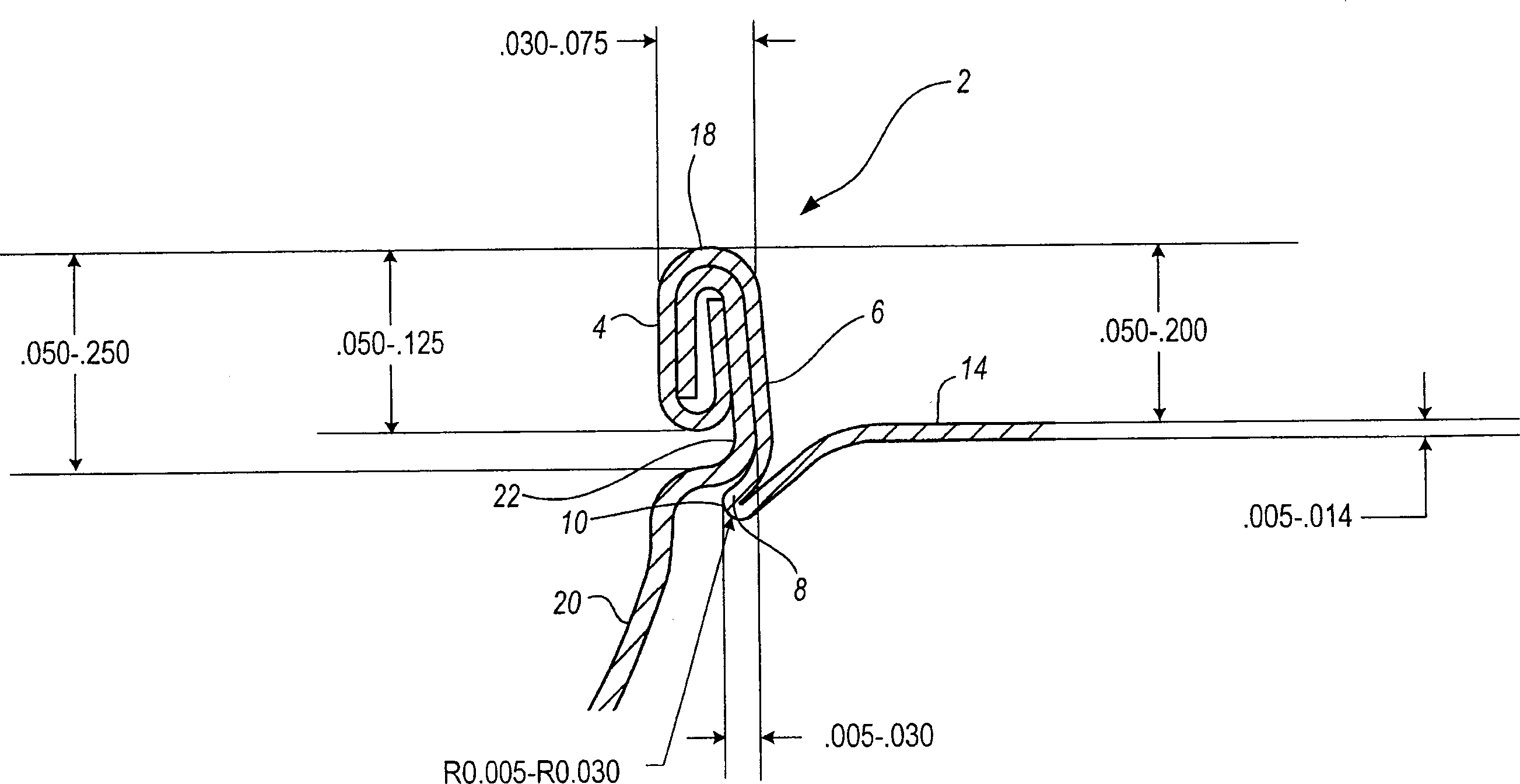

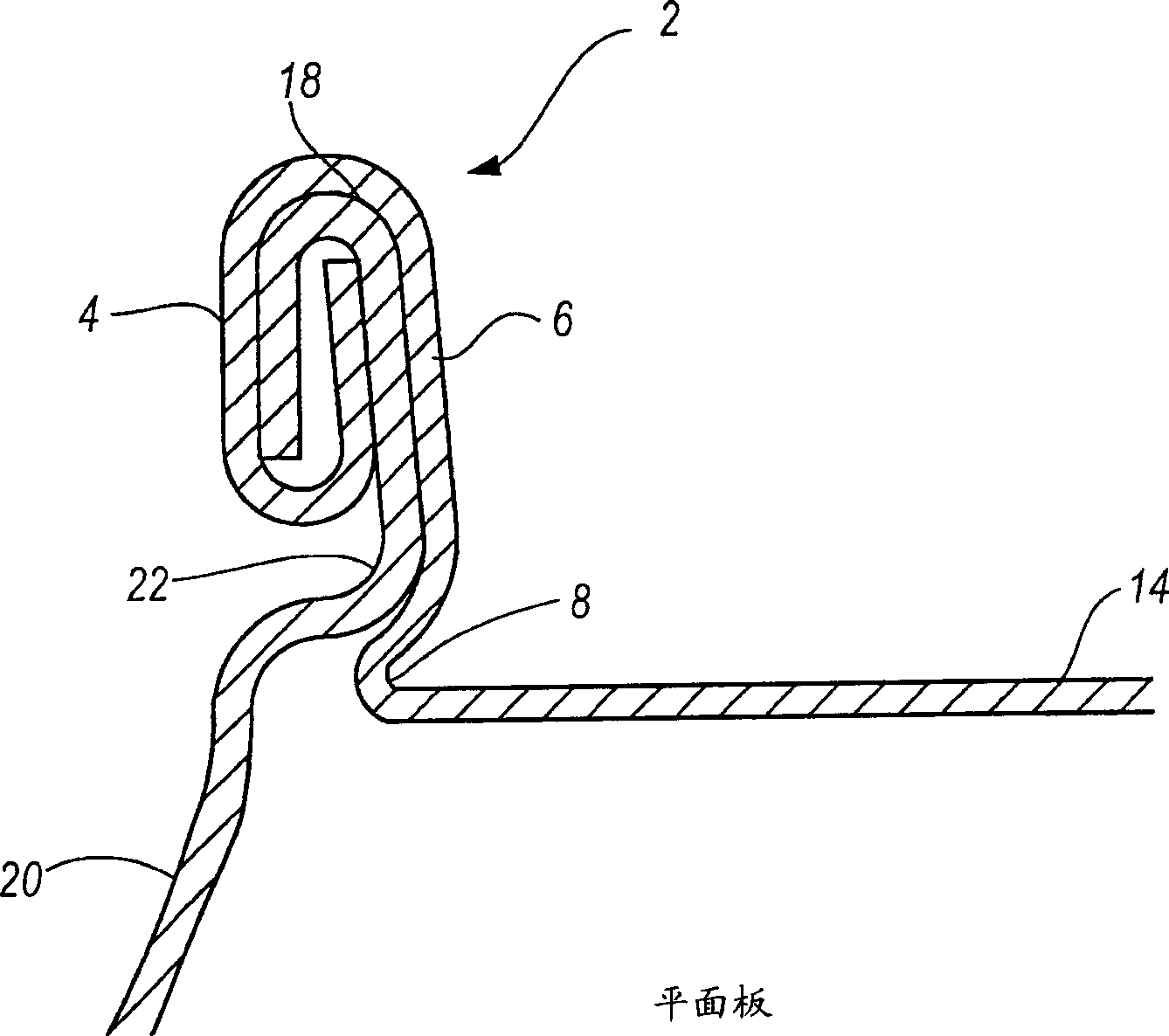

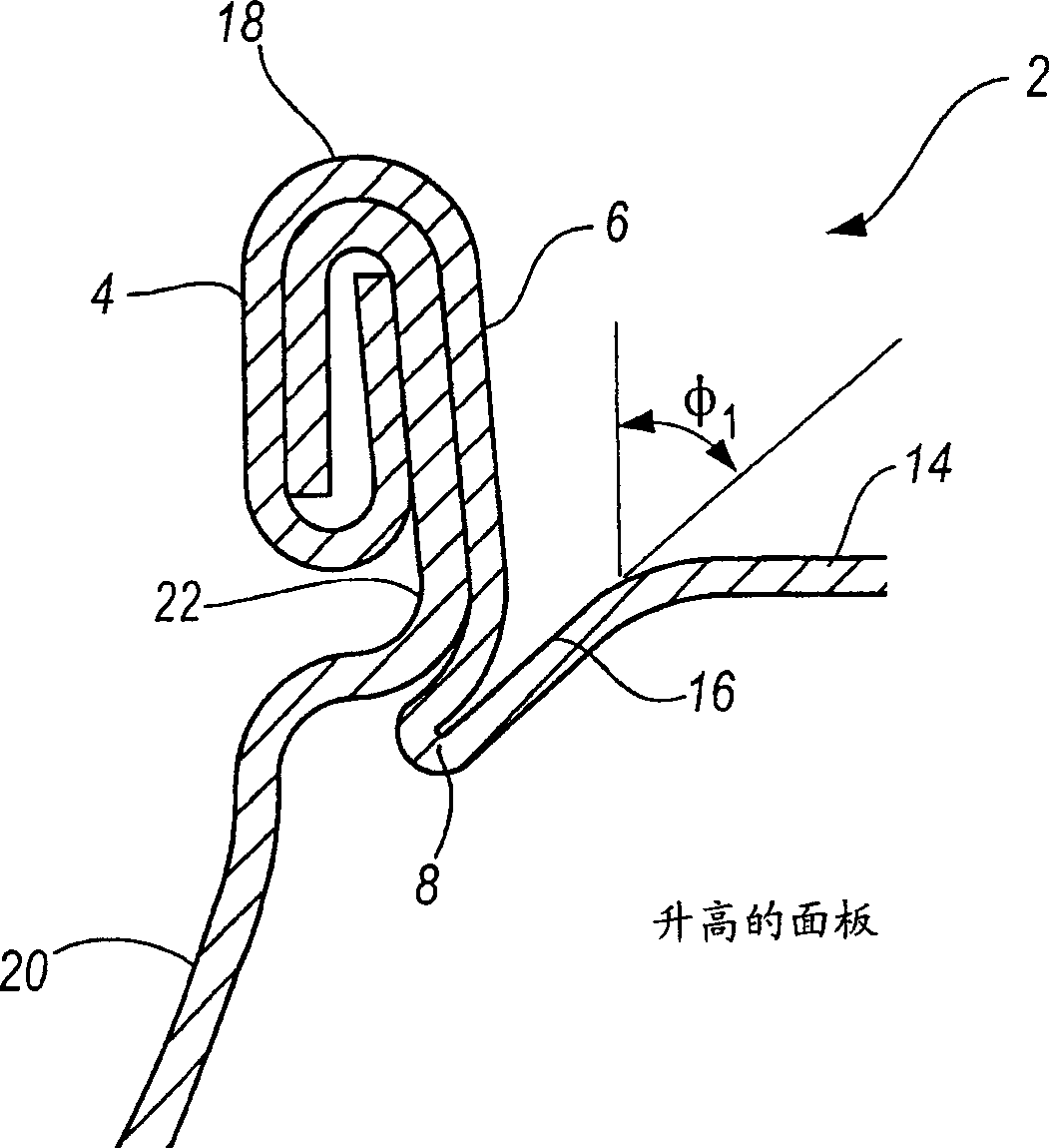

[0024] Refer to the attached figure 1 , in which a cross-sectional elevation view of one embodiment of the invention is provided. More particularly, a beverage can end 2 is depicted interconnected with a beverage can body 20, which also includes a neck 22 of the beverage can. The beverage can end 2 typically has an edge-covering bead 4 which is used to secure the beverage can end 2 to the neck 22 of the end of the beverage can body. The edge-covering bead 4 is integrally connected to one another with a fixed wall 6 which extends downwards in a substantially vertical manner. In some embodiments, the fixed wall 6 may be provided with an angle θ 1 , preferably said angle is between 0°-6°, more preferably 4°.

[0025] The lower end of the fixed wall 6 is interconnected with a reinforcing flange 8 comprising an upper lip 10 at the upper end of the reinforcing flange, and a lower lip 12 of the reinforcing flange at the lower end. The lower lip 12 of the reinforcing flange extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com