Contactless liquid sample collecting and packaging system

A liquid sample and sub-packaging system technology, applied in sampling devices and other directions, can solve the problems of long collection time, inability to carry out, and high price, and achieve the effects of low equipment requirements, large scope and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

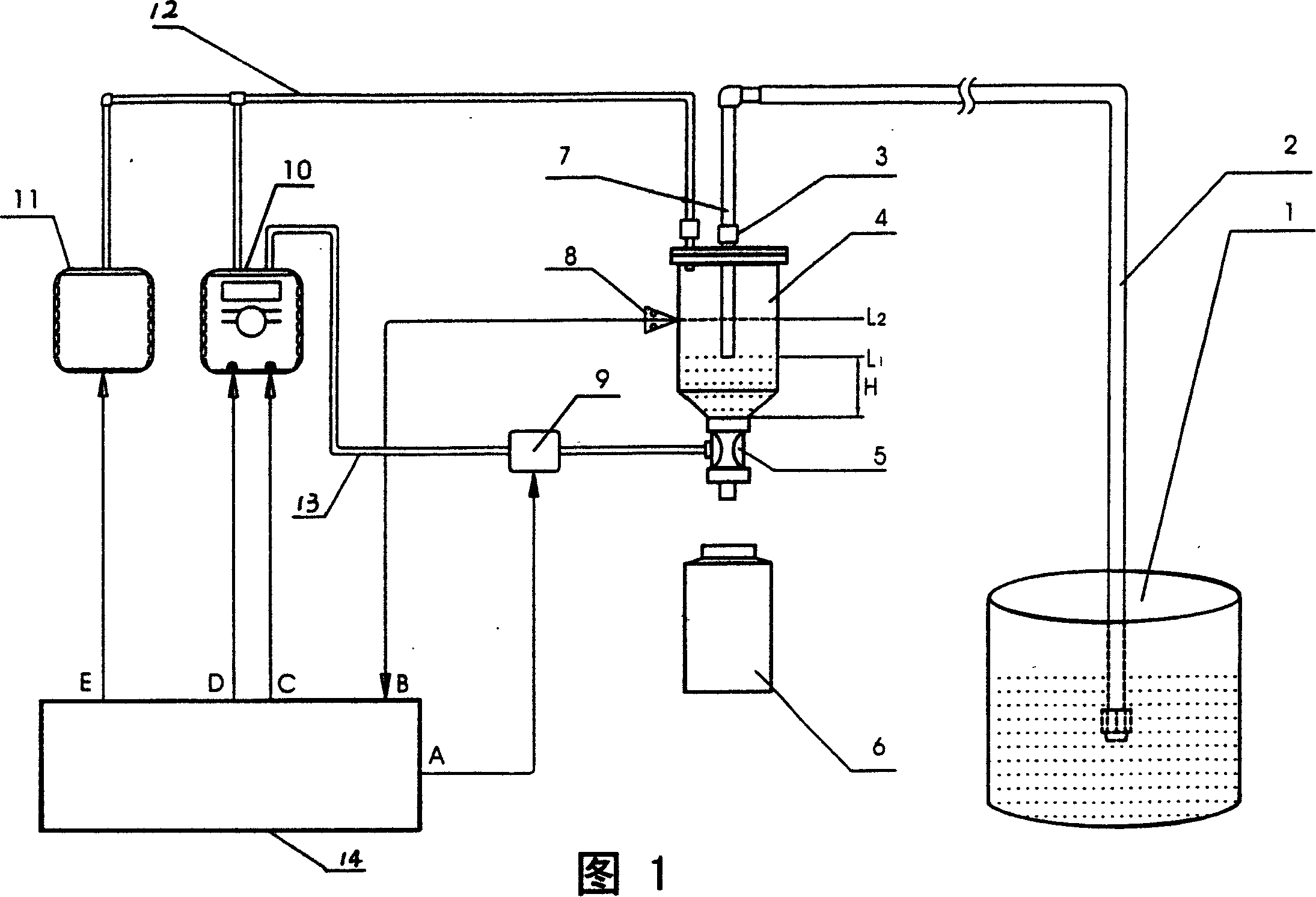

[0013] A non-contact liquid sample collection and packaging system consists of a sample tank (1), a collection tube (2), a quantitative tube regulator (3), a collection bottle (4), a pneumatic clear / turbid fluid blocking valve (5 ), mining and bottling (6), metering tube (7), water level detector (8), solenoid valve (9), rotary anti-oil return vacuum / pressure excavation dual-purpose pump (10), oil-free air pump (11 ), compressed gas and air suction dual-purpose pipeline (12), gas pipeline (13), process controller (14), the process controller (14) is connected with the water level detector (8), solenoid valve respectively with wires (or remote control) (9), the rotary anti-oil return vacuum / compressed air dual-purpose pump (10), and the oil-free air pump (11) are connected, and one end of the compressed air and air suction dual-purpose pipeline (12) is inserted in the collection bottle (4), and one end is connected to the collection bottle (4). The suction port of the rotary an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com