Heat treatment system and formable vertical chamber

A technology of processing chamber and processing area, applied in the system field of heat-treating objects, can solve problems such as high cost and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

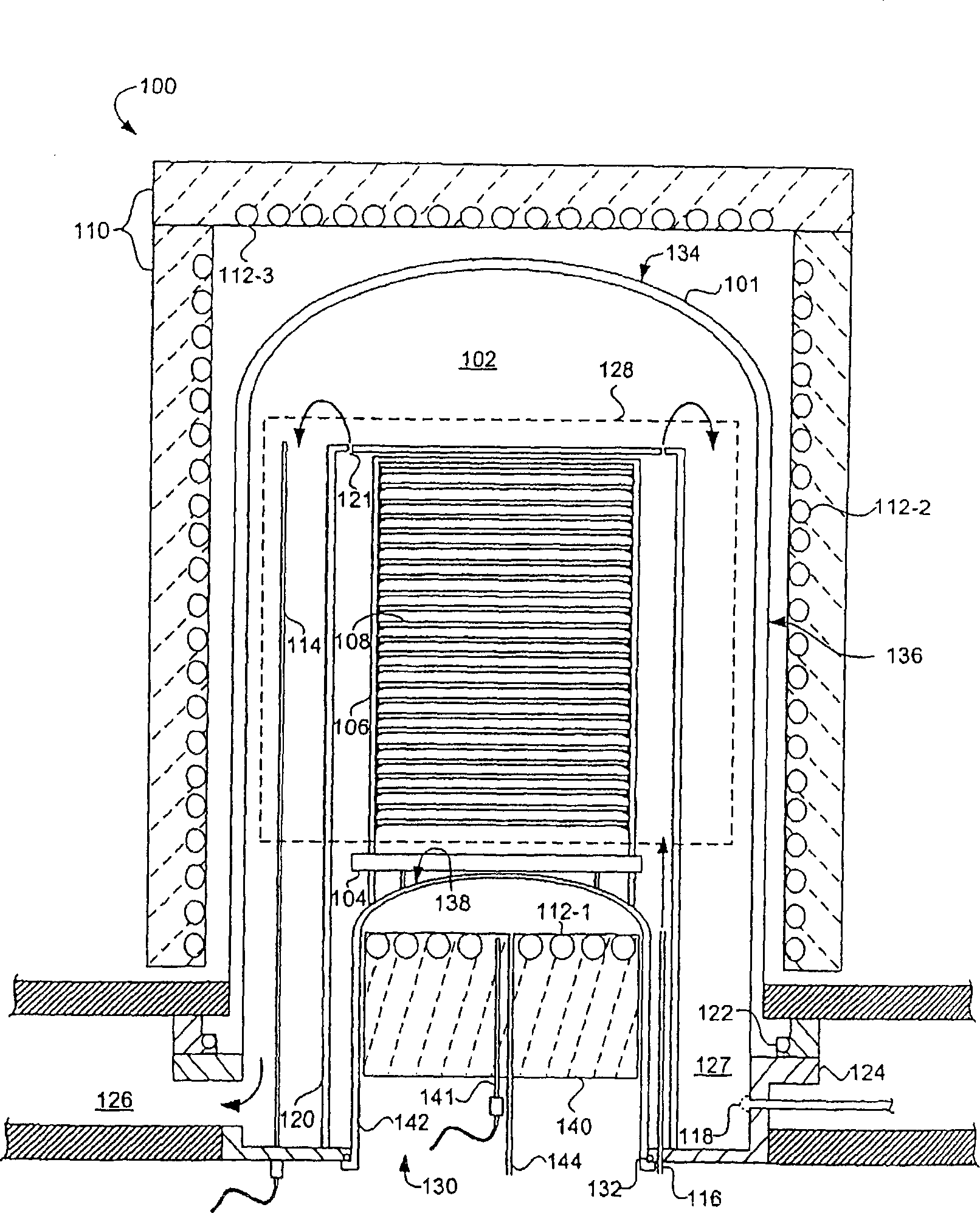

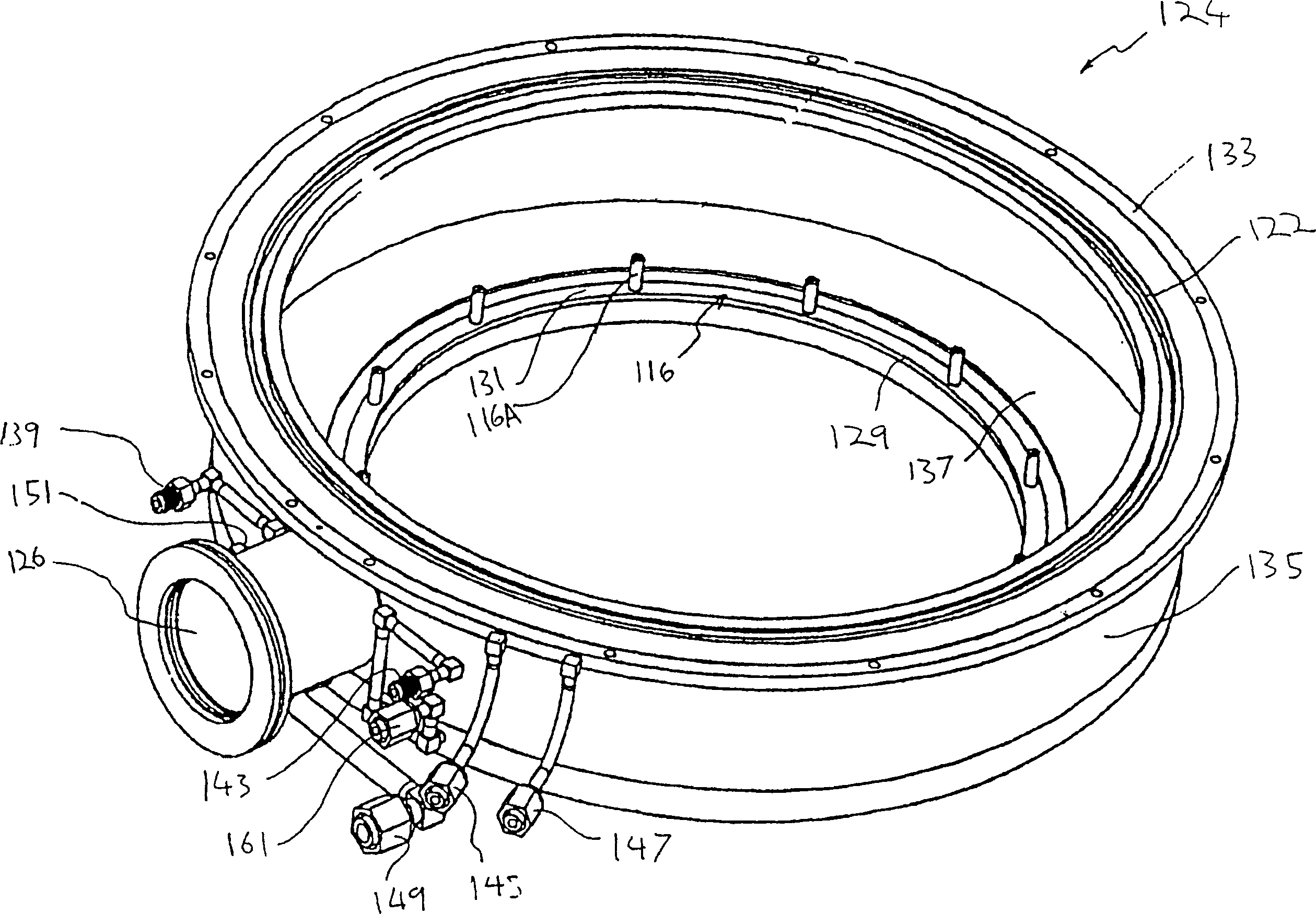

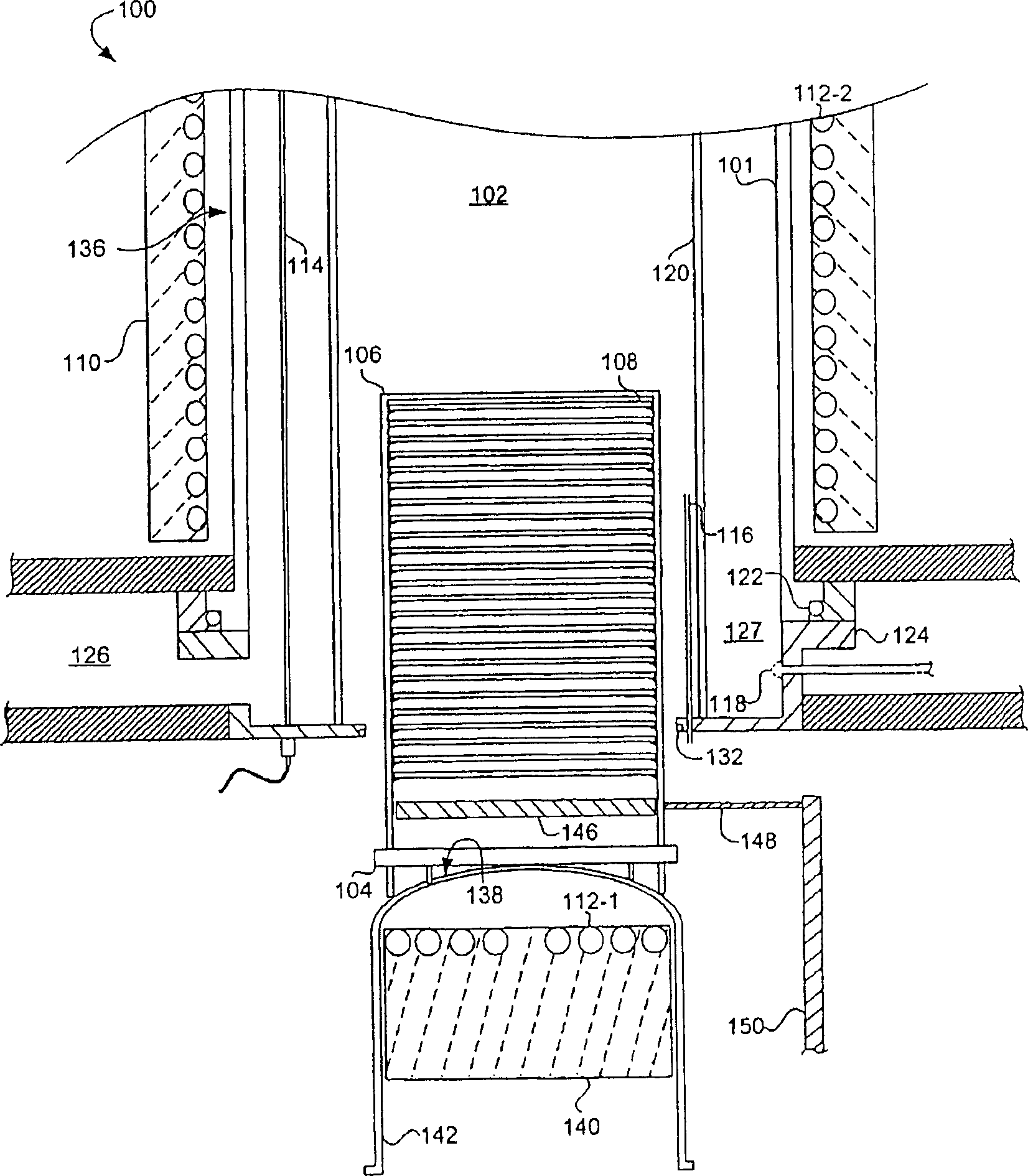

[0045] The present invention provides an apparatus and method for processing small quantities or batches of one or more workpieces, such as semiconductor substrates or wafers, carried on a carrier, such as a cassette or vaporizer, so that Reduce processing cycle time and improve processing uniformity.

[0046] As used herein, the term "small batch" refers to a number of wafers that are less than several hundred wafers in a typical batch system, preferably in the range of 1 to about 53 semiconductor wafers, or where 1 to 50 semiconductor wafers are finished wafers, while the rest are non-finished wafers used for monitoring purposes and as blanker wafers.

[0047] Heat treatment refers to the process of heating the workpiece or wafer to a desired temperature in the range of about 350°C to 1300°C. Thermal processing of semiconductor wafers may include thermal treatment, annealing, diffusion or driving of dopant materials, deposition or growth of layers of material (eg, chemical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com