Method of producing fuses

A fuse and lead technology, used in fuse manufacturing, electrical components, electrical switches, etc., can solve problems such as defective fuses and difficult leads to be fixed in the required position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] best practice

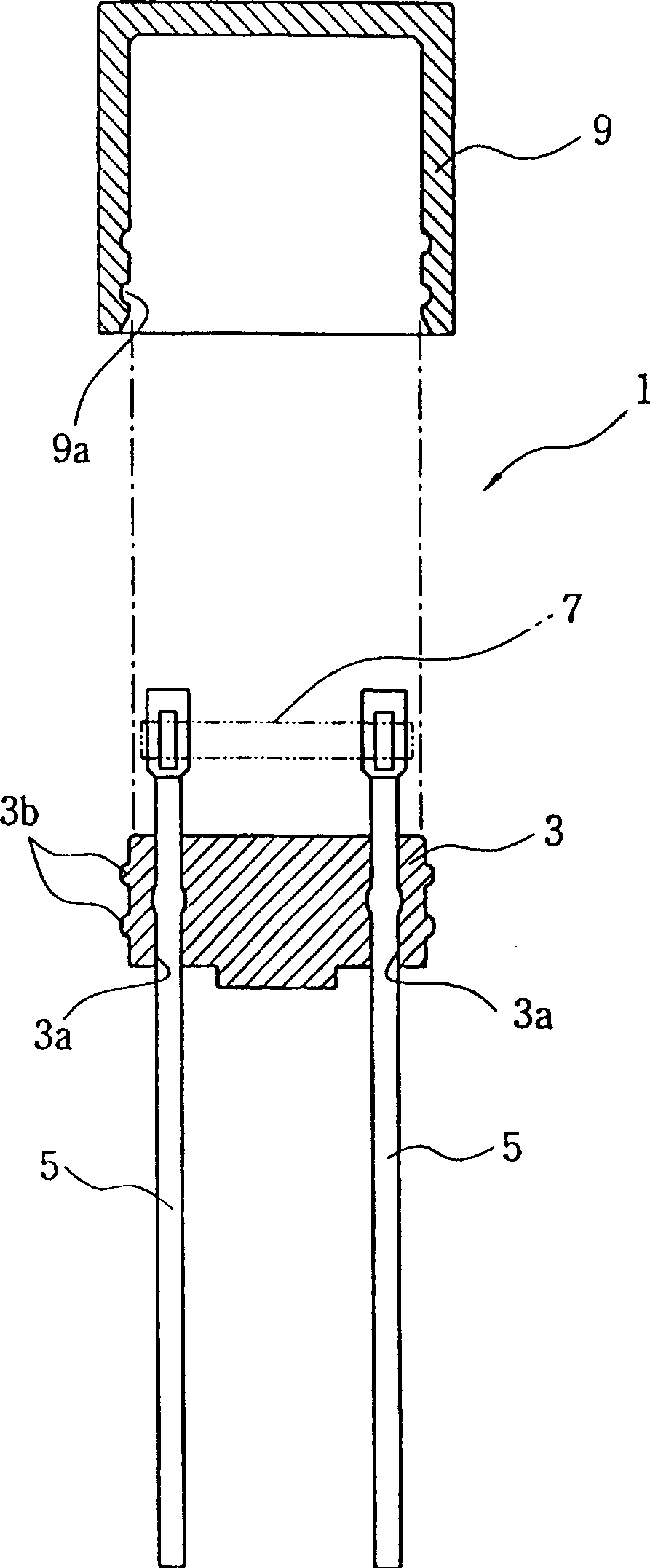

[0024] A preferred method of producing a fuse according to the present invention will be described below with reference to the accompanying drawings. In this document, the term "die-cut" refers to a semi-finished product obtained by stamping a metal sheet into a plurality of lead-conductor pairs.

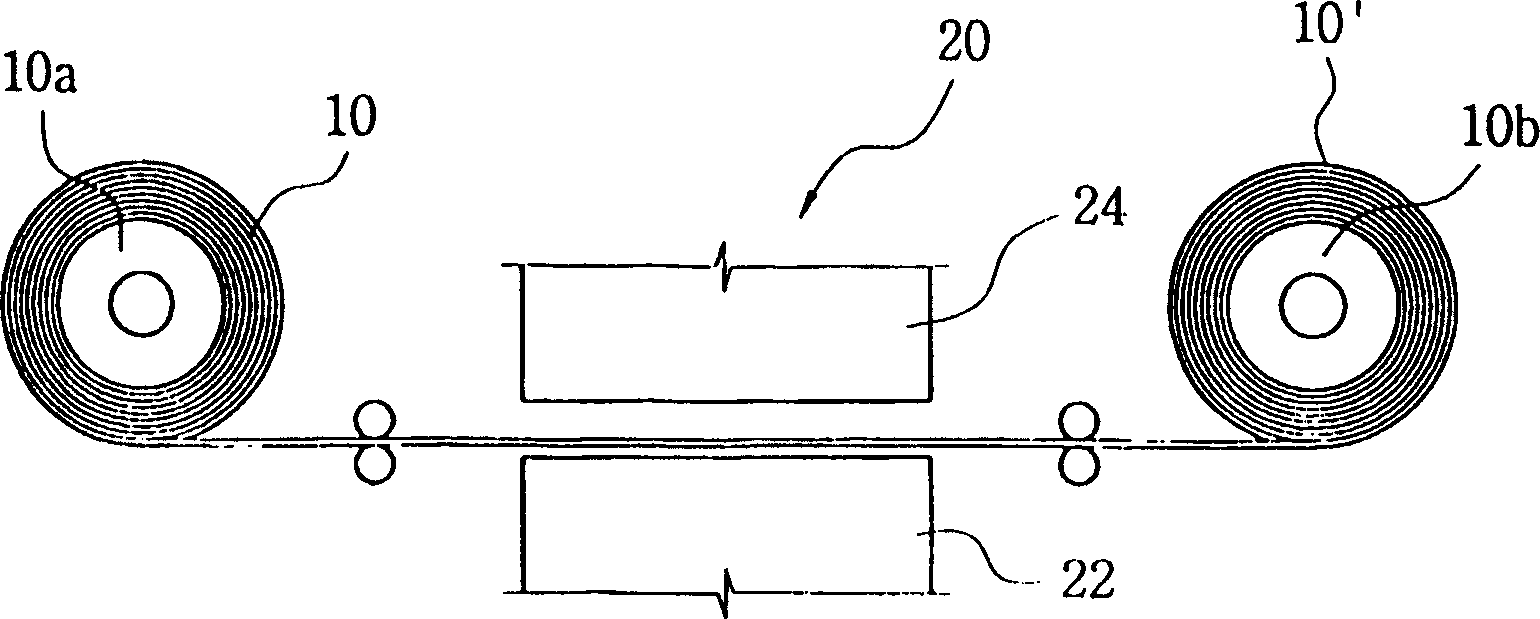

[0025] Figures 2A to 2H shows a series of steps employed in a method for producing a fuse according to a preferred embodiment of the present invention, and Figures 3A to 3E The configuration of the metal sheet formed in the various steps of the method of the invention is shown.

[0026] The fuse production method according to the present invention uses a metal sheet 10, such as Figure 2A As shown, it may be a coiled continuous strip. The sheet metal 10 is intermittently unwound from a supply reel 10a and conveyed to a take-up reel 10b. An example of the metal sheet 10 may be a copper sheet. The width and length of the metal piece 10 are appropriately ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com