Construction of concrete piles

A construction method, technology of concrete piles, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., to achieve the effect of saving building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

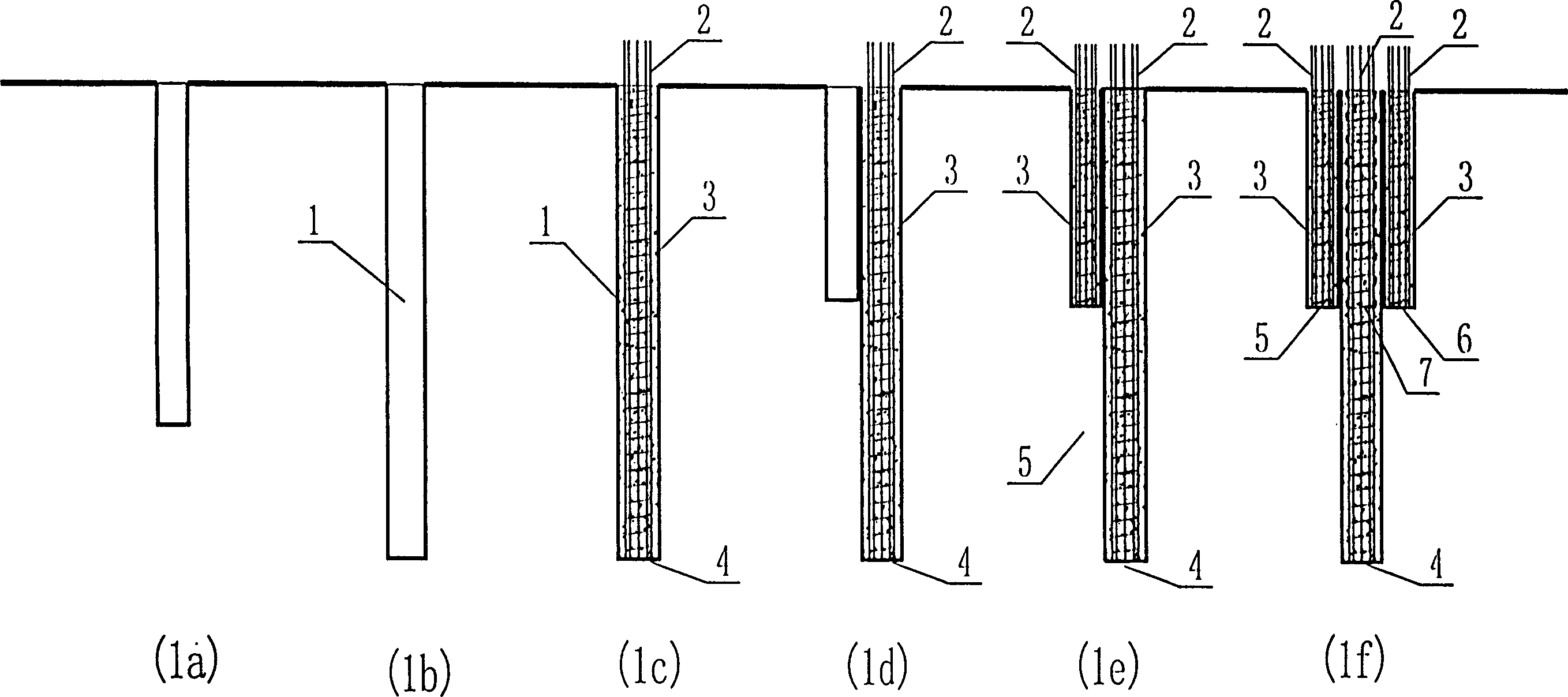

[0022] The construction method of the concrete pile that is made up of 3 piles as an embodiment of the present invention, it comprises the following steps, at first, as figure 1 As shown in a, according to the geological exploration report and the load on the upper part of the building, a better foundation soil is selected as the bearing layer at the pile end, and the hole is formed after the pile position is selected on the foundation; then, as figure 1 As shown in b, the pile hole 1 is formed according to the design depth; then, as figure 1 As shown in c, a reinforcement cage 2 is placed in the pile hole 1, and concrete 3 is poured to form a central stressed pile 4; after that, as figure 1 As shown in d, a hole is formed close to the central force-bearing pile, and the depth of the hole is less than the length of the pile body of the central force-bearing pile, and greater than 5 to 6 times the pile diameter of the central force-bearing pile; then, as figure 1 As shown in e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com