Threading/tapping control apparatus

A technology of control device and control unit, which is applied in the direction of automatic control device, feeding device, program control, etc., and can solve problems such as reduced accuracy of buckle picking, increased synchronization error, and synchronization error of workpiece and tool.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following description of the preferred embodiments with reference to the accompanying drawings will make these and other objectives and features of the present invention clearer.

[0025] Hereinafter, embodiments of the present invention will be described together with the drawings.

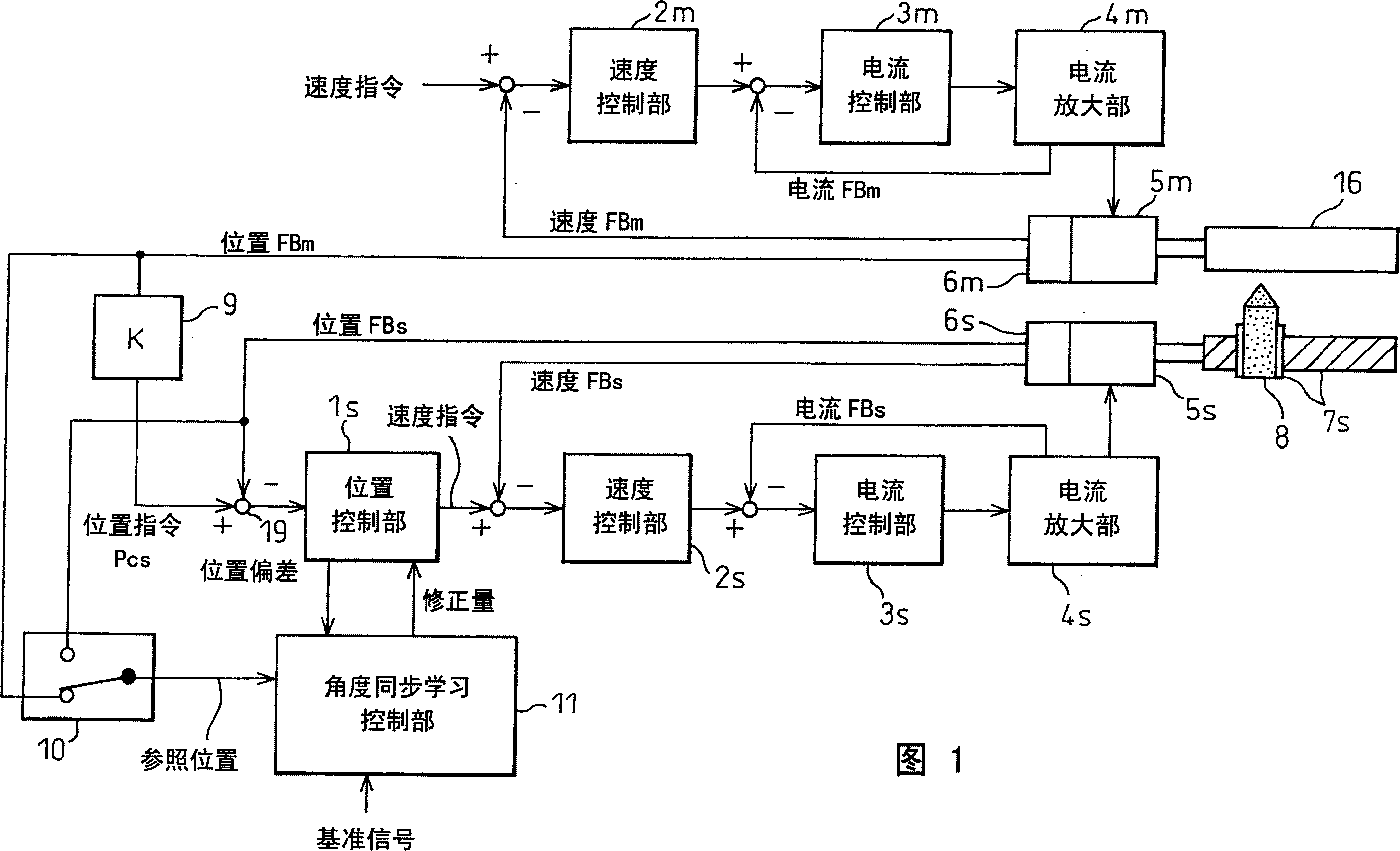

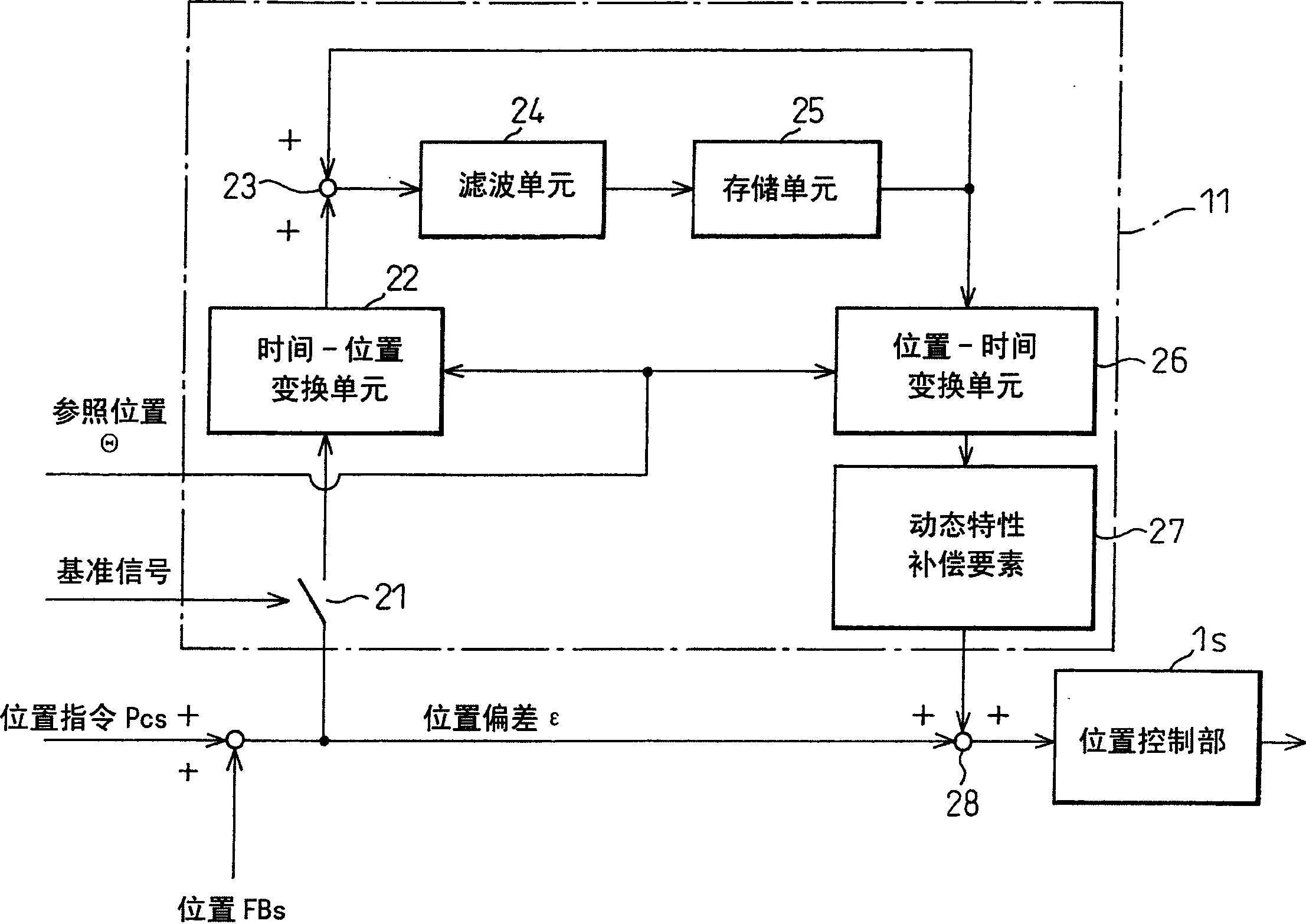

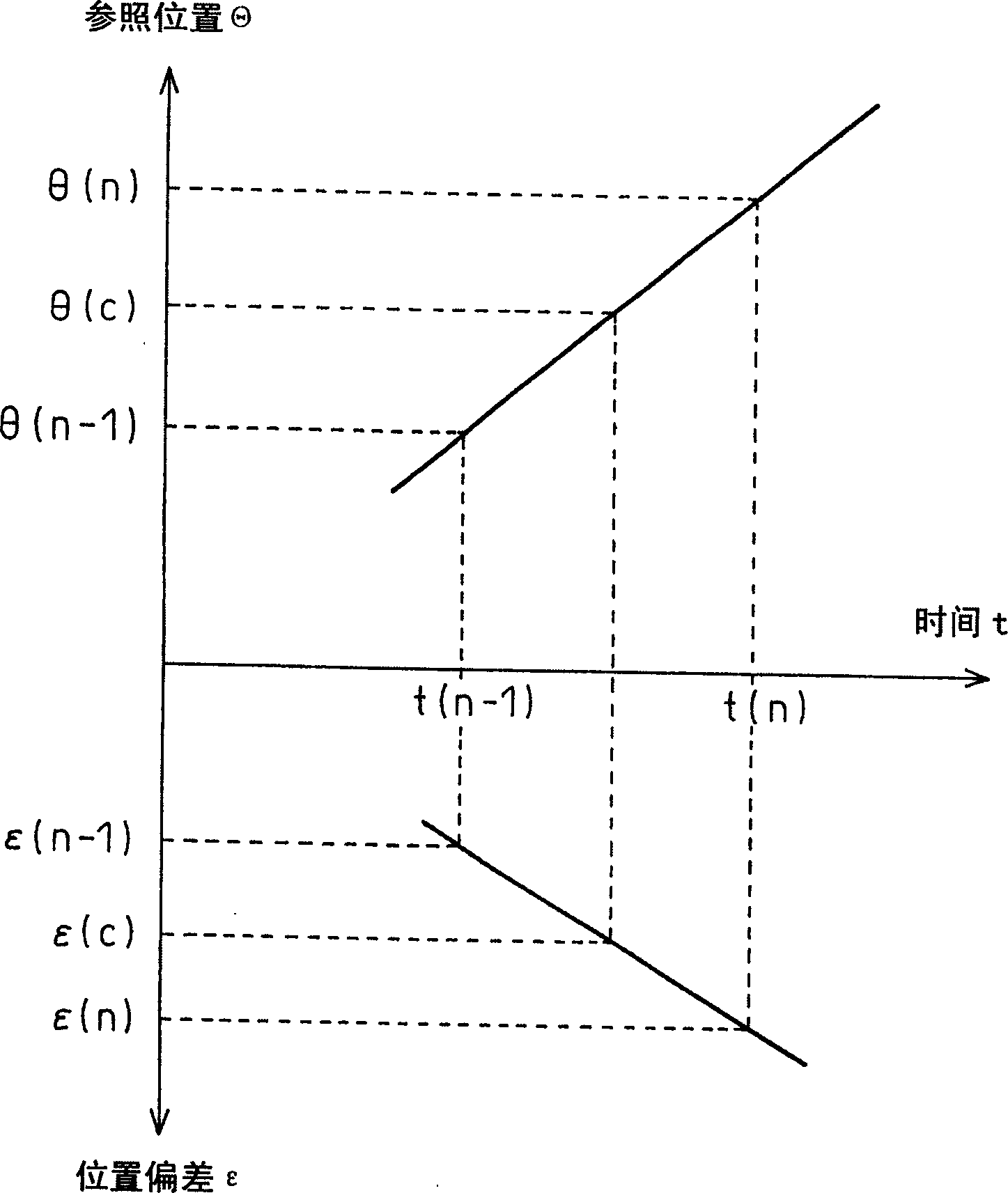

[0026] Fig. 1 is a block diagram of the first embodiment of the present invention. This embodiment is an example of picking and snapping the workpiece 16. In this example, the workpiece is rotated by the motor 5m, and the tool (cutter) is moved toward the center of rotation of the workpiece 16 according to the ball screw / nut mechanism 7s driven by the slave motor 5s. Axis direction movement.

[0027] The speed feedback from the position and speed detector 6m is subtracted from the speed command output by the upper control device such as the numerical control device to obtain the speed deviation. The position and speed detector 6m is installed on the main motor 5m and detects the main motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com