Prestressed tensioning system

A prestressing and tensioning technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of insufficient equipment accuracy, poor synchronization, affecting the measurement of pressure and stretching length, etc., to improve timeliness and accuracy high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

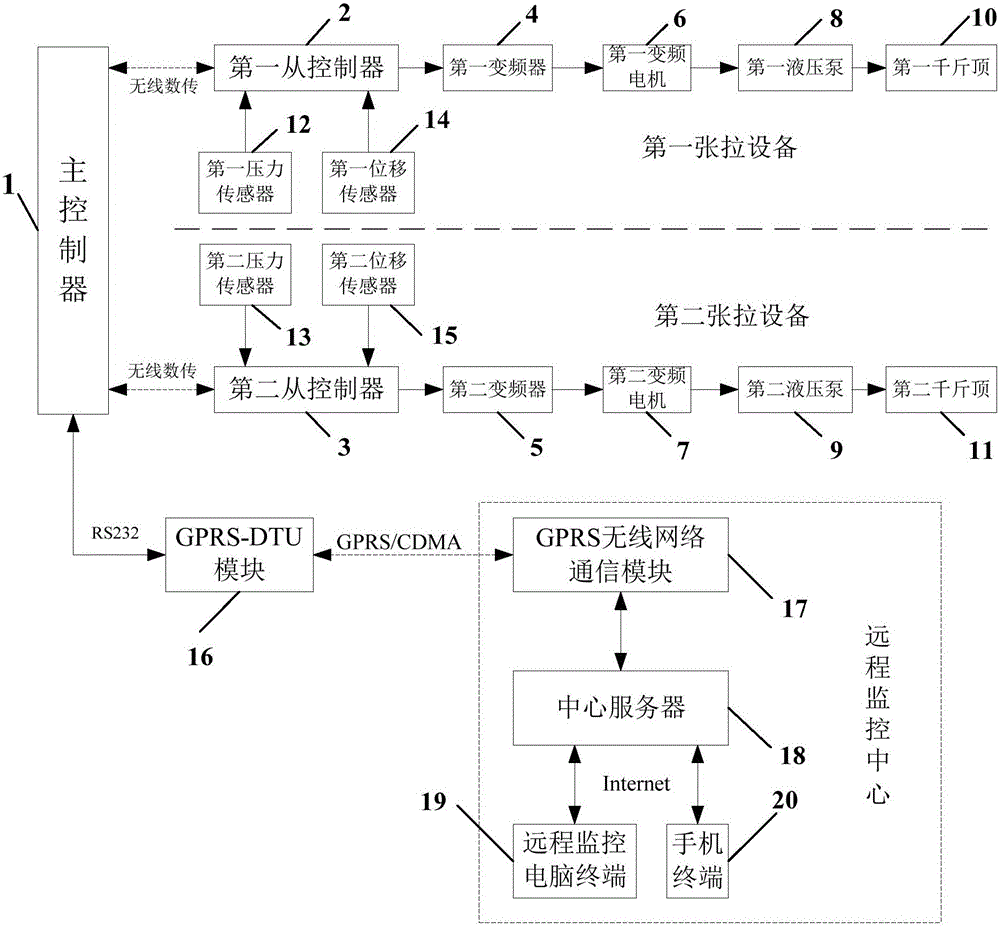

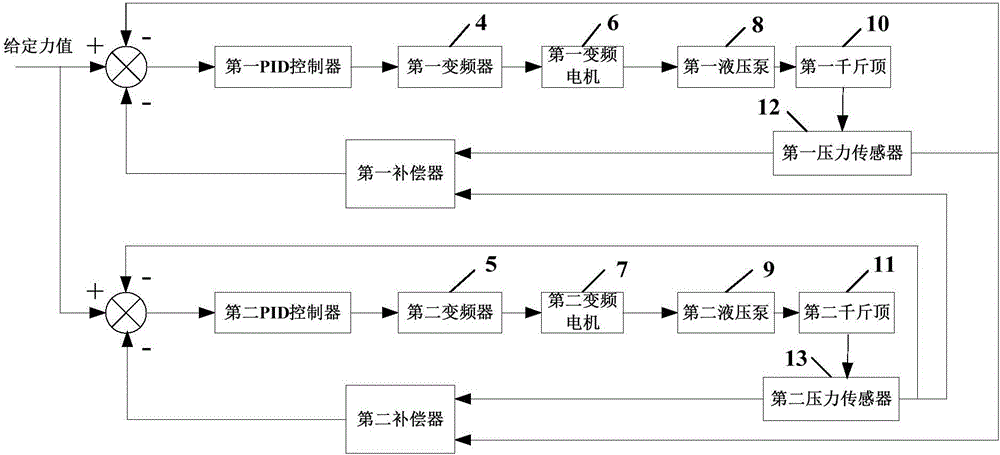

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] see figure 1 , the present invention structurally includes a master controller 1 and a first slave controller 2 and a second slave controller 3 that are wirelessly connected to the master controller 1 through a wireless data transmission module, the master controller 1, the first slave controller 2 and the second slave controller 3 are respectively connected to their respective wireless data transmission modules through the RS232 interface. The first slave controller 2 is connected to the first jack 10 through the first frequency converter 4, the first variable frequency motor 6 and the first hydraulic pump 8 in sequence, and the second slave controller 3 is connected to the first jack 10 through the second frequency converter 5 and the second frequency converter in sequence. The motor 7 and the second hydraulic pump 9 are connected to the second jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com