Printing method and image forming apparatus for performing the same

A technology of imaging equipment and printing direction, applied in the direction of printing device, printing, transfer materials, etc., can solve the problems of paper not being fed normally, skewed, paper skewed to one side, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

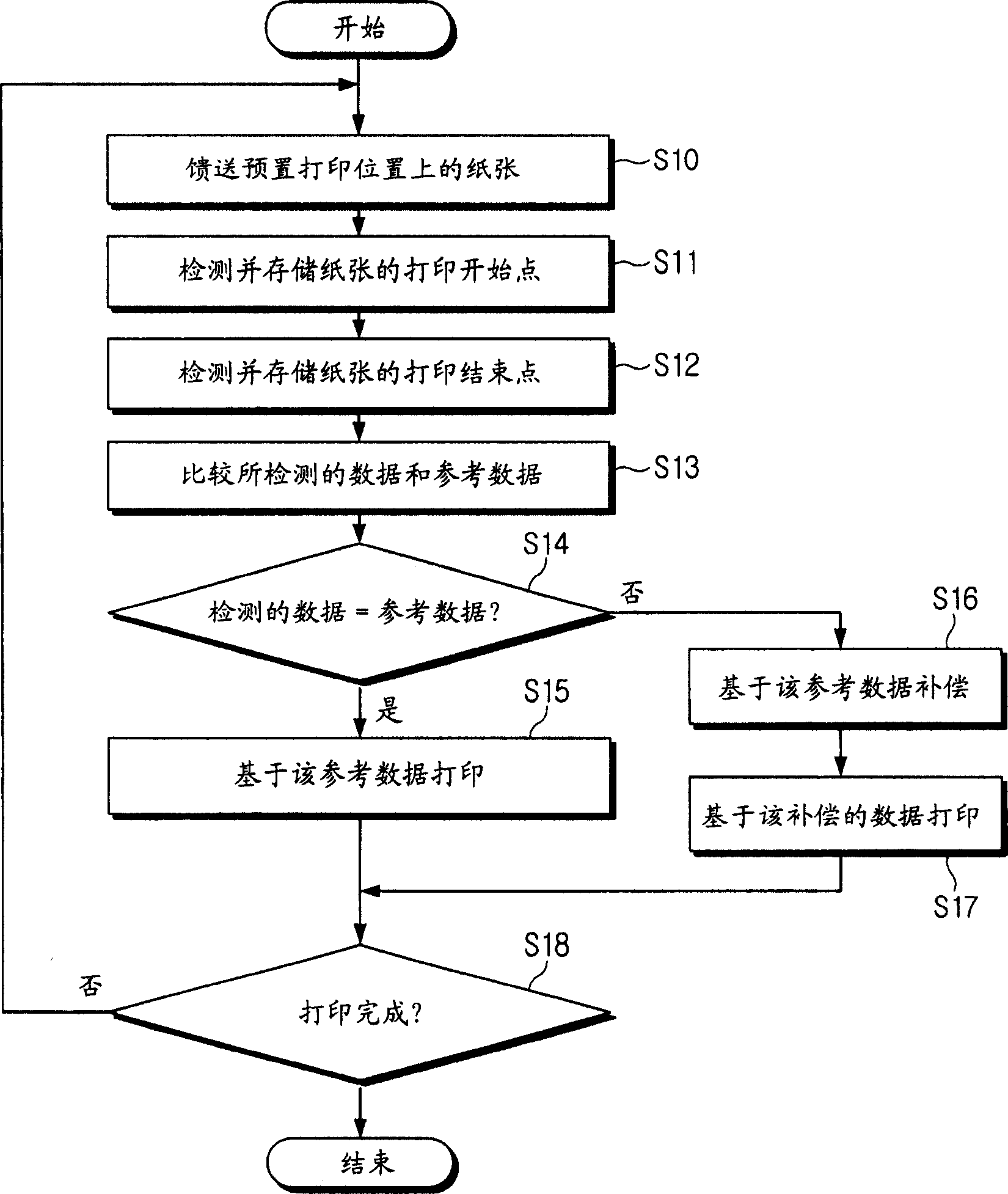

[0017] Specific embodiments of the present invention will now be described in more detail with reference to the accompanying drawings.

[0018] In the following description, it should be understood that the same reference numerals are used for the same elements, features and structures throughout the drawings. Matters defined in the description, such as detailed constructions and elements, are provided to assist in a comprehensive understanding of the present invention. Therefore, it is obvious that the embodiments of the present invention can be implemented without the content of these definitions. Also, well-known functions or constructions are omitted for brevity.

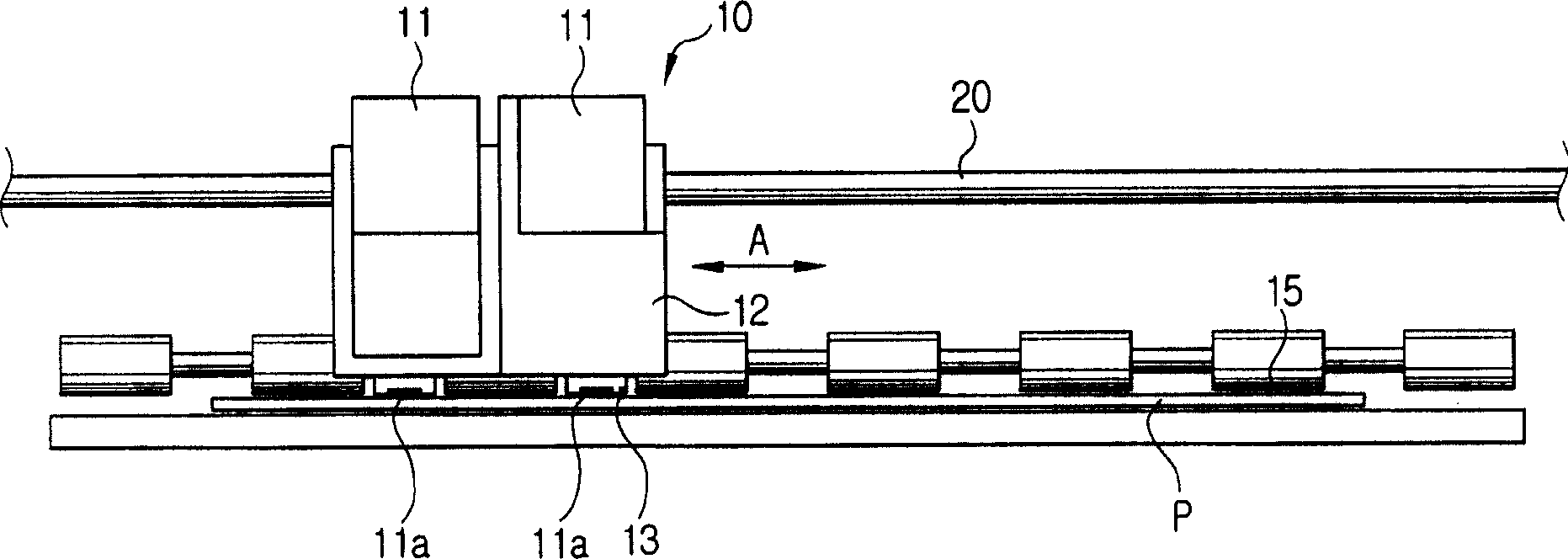

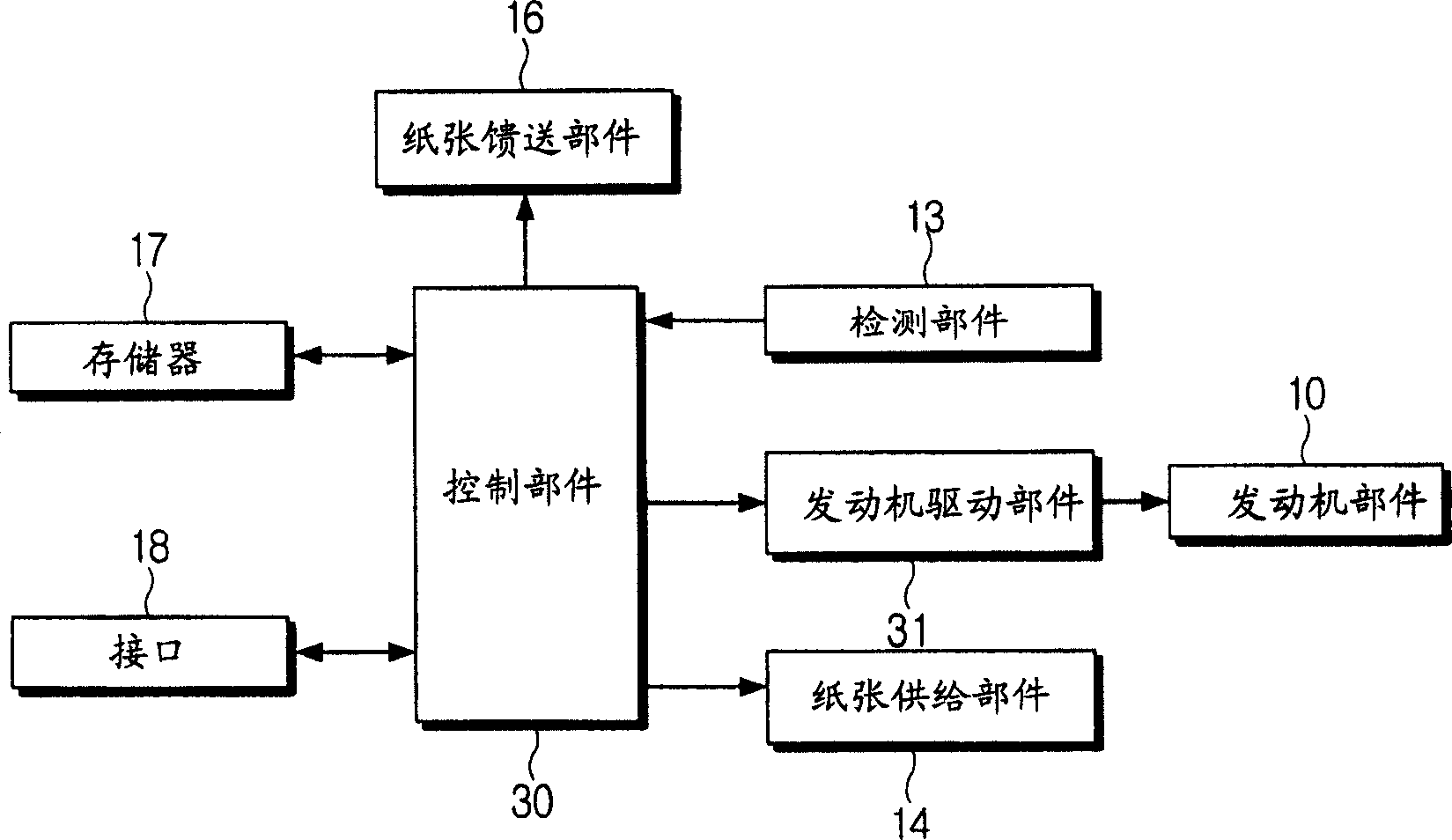

[0019] figure 1 and figure 2 They are a schematic diagram and a block diagram of an inkjet printer for explaining a printing method of an image forming apparatus according to an embodiment of the present invention, respectively.

[0020] In the ink jet printer, the engine part 10 including the carriage 12 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com