Method for detecting fabric texture

A fabric texture and detection method technology, which is applied in the inspection of textile materials, textiles and papermaking, etc., can solve the problems of inaccurate alignment and achieve the effect of overcoming inaccurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

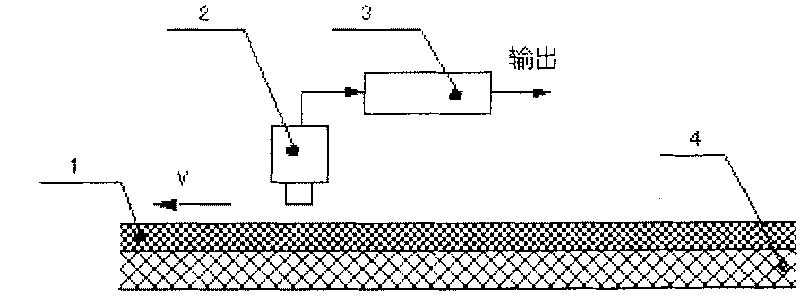

Method used

Image

Examples

Embodiment 3

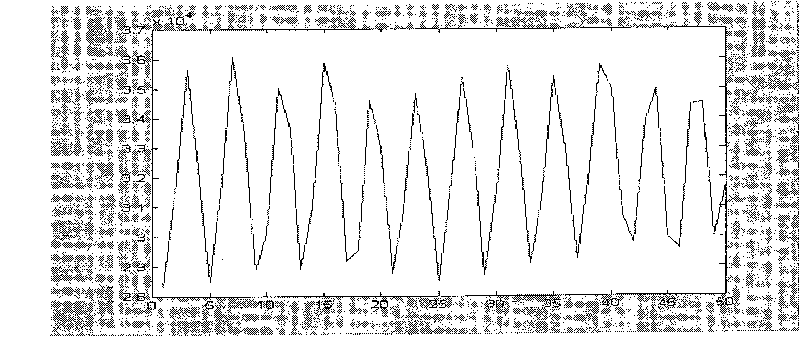

[0035] Embodiment 3 is basically the same as Embodiment 1 and Embodiment 2, the difference is that the fabric texture feature extraction device uses photocells, the width of the photosensitive area is less than 1 / 2 of the grain spacing, and the length of the photosensitive area is greater than ten grain spacings , the length direction of the photosensitive area is parallel to the weave direction of the fabric to be detected, and the photosensitive device perceives the alternating changes in the intensity of light generated by the movement of the fabric weave, and converts it into an alternately changing level signal, which is used as the weaving texture on the surface of the moving fabric Information, the computer samples the output level of the photocell, and directly performs digital filtering on the sampling result. In embodiment 3, the photocell can be replaced by photosensitive devices such as photoresistors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com