Continuous construction method for tunnel emergency parking strip cast-in-situ lining by quickly disassembling and assembling trolley

A technology of emergency parking and trolley, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of time-consuming and labor-consuming, and achieve the effect of overcoming inaccurate positioning, stable formwork, and convenient and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

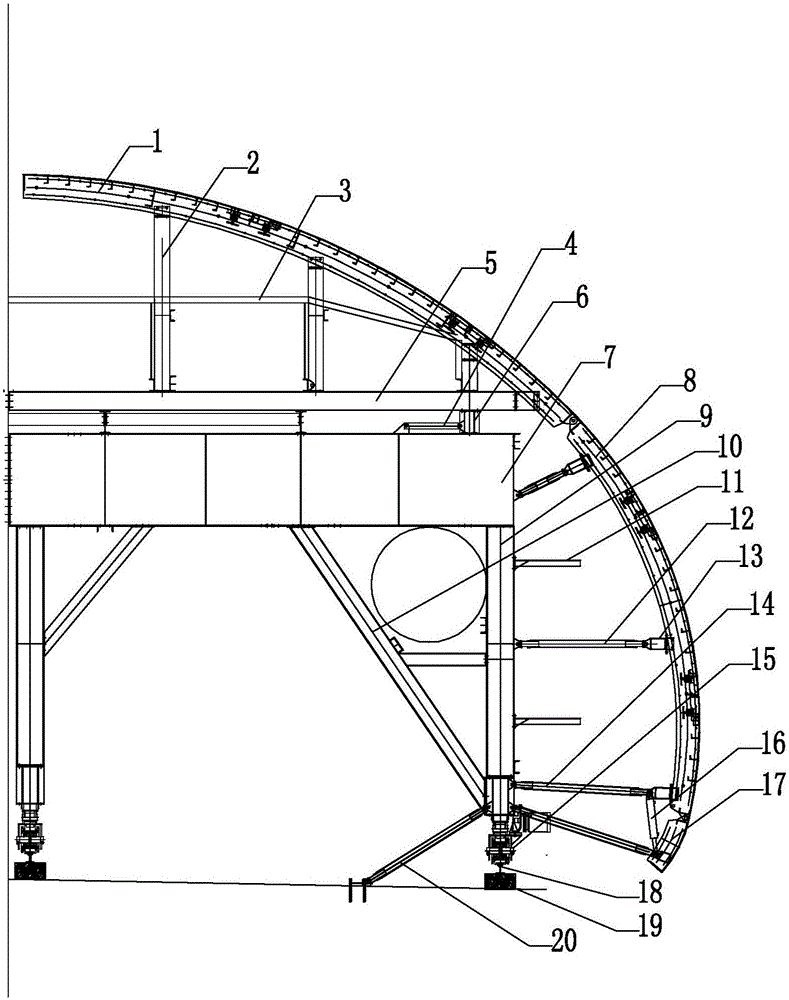

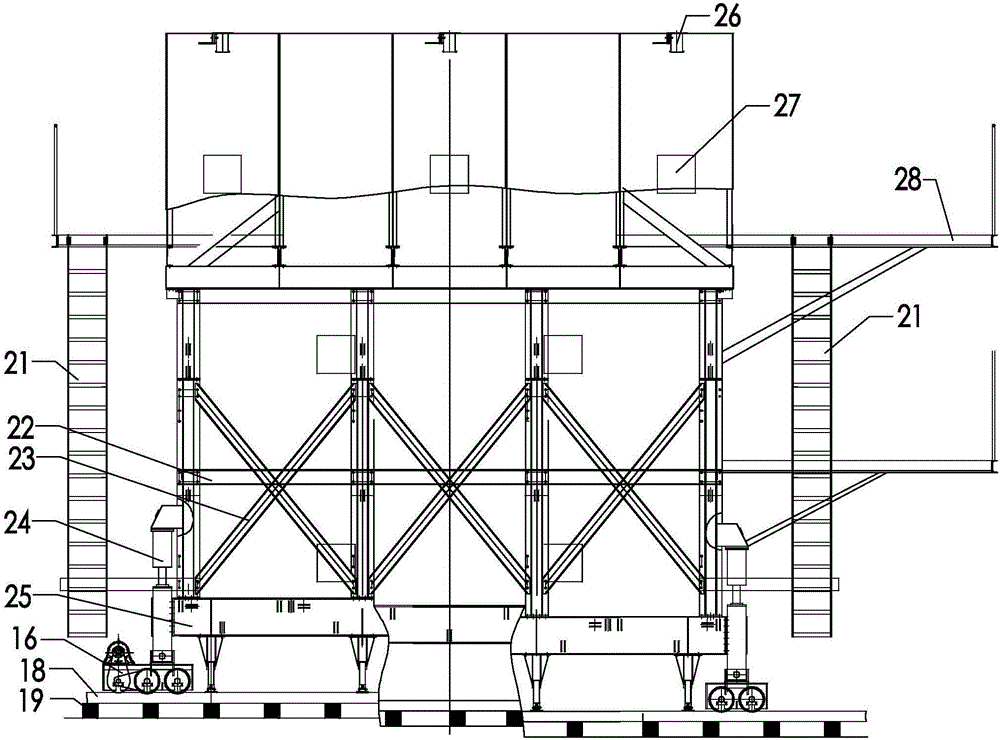

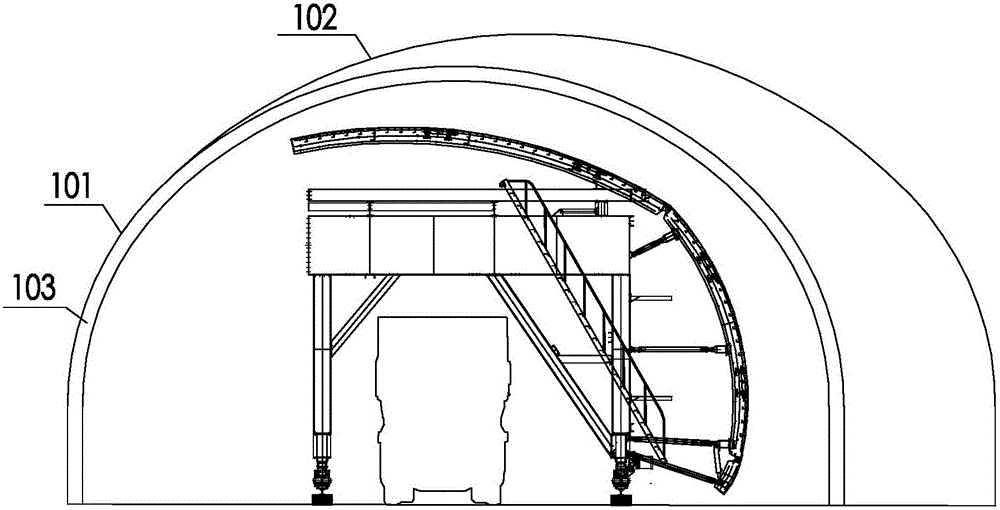

[0033] The trolley used for the cast-in-place lining of the emergency parking zone of the tunnel of the present invention is as follows: figure 1 , figure 2 As shown, it includes upper formwork assembly 1, bracket column 2, horizontal connecting rod 3, bracket beam 5, door frame beam 7 and other components. The trolley is composed of two symmetrical half trolleys. A complete trolley is connected by the butt pins and butt bolts provided at the corresponding positions of the upper formwork assembly 1, the bracket beam 5 and the mast beam 7.

[0034] When the bracket column 2 and the horizontal connecting rod 3 are removed, the butt pins and butt bolts set at the corresponding positions of the upper formwork assembly 1, the bracket beam 5 and the door frame beam 7 are removed at the same time, and after the upper formwork assembly 1 is rotated downward, It is also possible to split the entire trolley into two half-width trolleys.

[0035] In the present invention, a continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com