Transformer core laminating method

A transformer and iron core technology, applied in the field of transformer core laminations, can solve problems such as uneven distribution of core magnetic flux density, affecting reliable operation of products, transformer iron loss and no-load current increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

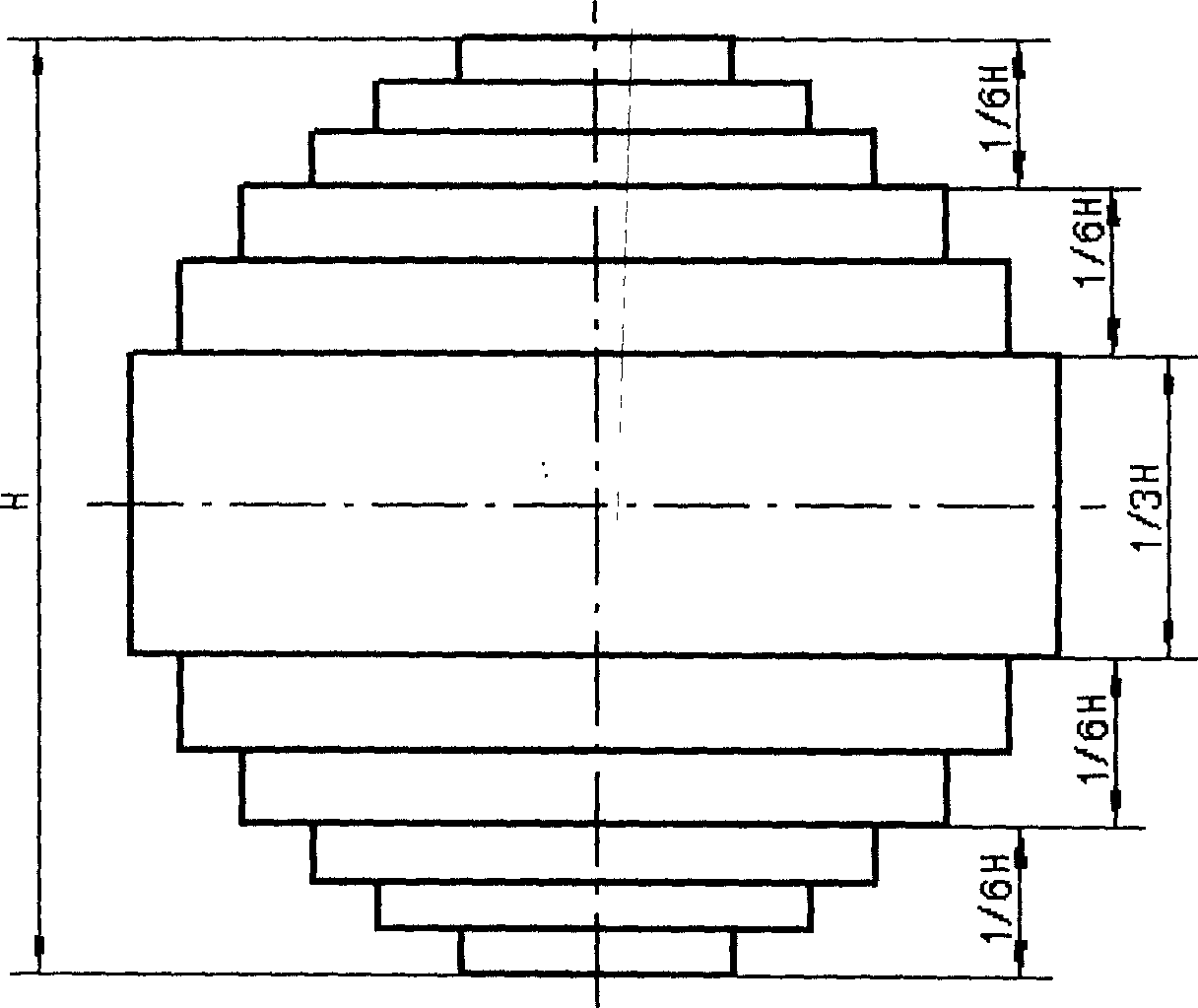

[0009] The invention relates to a method for stacking iron cores of a transformer, which is an organic combination of a one-piece stacking method, a two-piece stacking method and a three-piece stacking method. combine as figure 1 To explain in detail, the thickness of the core column is roughly divided into five parts. The total stacked thickness of the core is H, which is 1 / 6H, 1 / 6H and 1 / 3H from both sides to the middle. Among them, the two outermost parts of about 1 / 6H of the core column adopt the method of three-piece stacking, the two parts near the middle of about 1 / 6H adopt the method of two-piece stacking, and the middle part of about 1 / 3H adopts the method of stacking A stacked approach.

[0010]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com