Novel stator tooth pole structure and novel fan motor comprising same

A fan motor and stator tooth technology, applied in the magnetic circuit shape/style/structure, electric components, electrical components, etc., can solve problems such as the inability to meet the consumer end, the fan vibration becomes larger, etc., to improve the user experience and reduce the torque. The effect of chain wave and structure optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

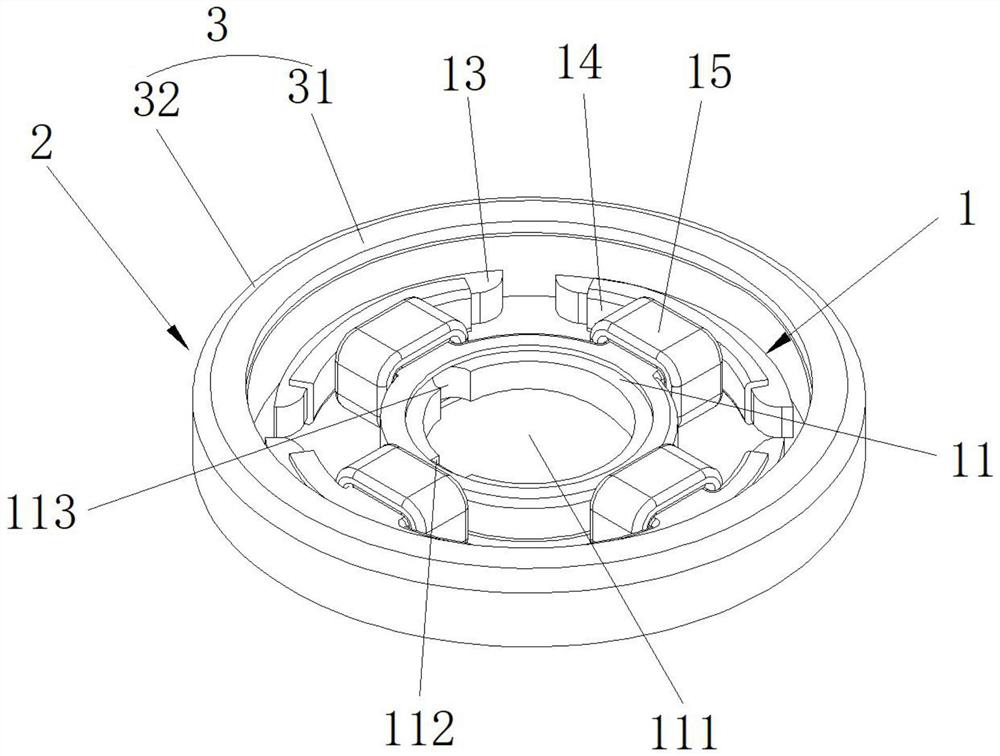

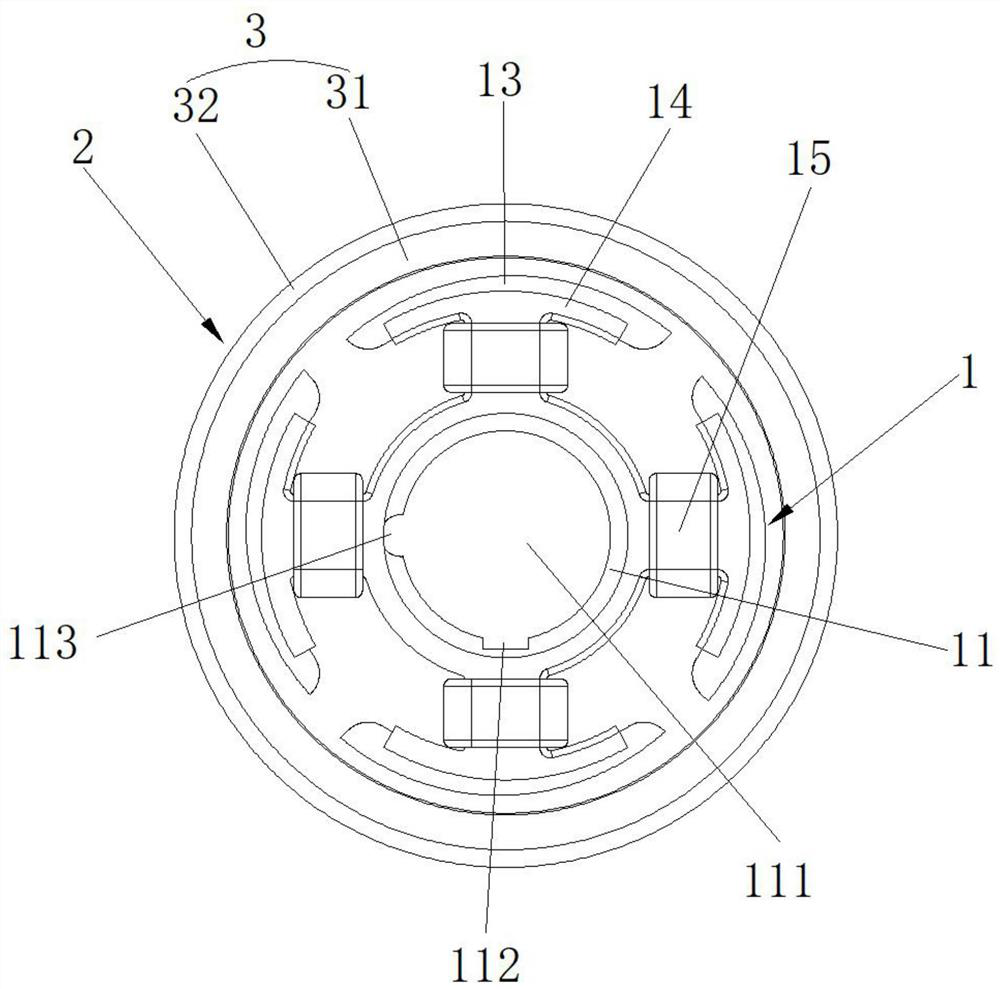

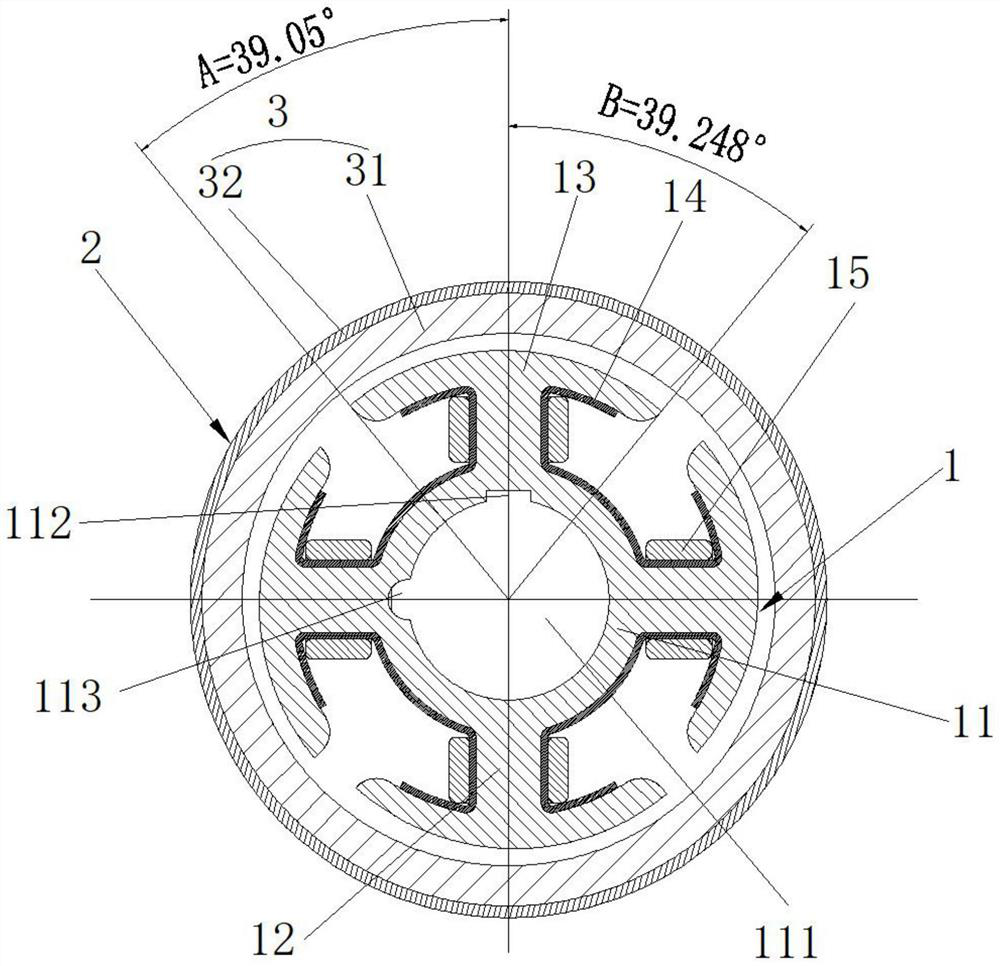

[0024] Please refer to Figure 1 to Figure 3 , the present invention provides a novel stator tooth pole structure, comprising a stator tooth pole body 1, the stator tooth pole body 1 includes an annular yoke portion 11, and the yoke portion 11 is provided with a tooth portion 12 extending outward, so The stator pole body 1 includes a plurality of tooth portions 12 uniformly arranged along the circumferential direction, and an arc-shaped tooth pole 13 is arranged on the end of the tooth portion 12, surrounded by the yoke portion 11, the tooth portion 12 and the tooth pole 13. An insulating layer 14 is installed on the inner part of the tooth part 12, and a winding 15 is wound on the outer side of the insulating layer 14 of the tooth part 12. The angle between one end of the tooth pole 13 of the stator tooth pole body 1 and the central axis is a small angle A, The angle between the other end of the tooth pole 13 of the stator tooth pole body 1 and the central axis is a larger an...

Embodiment 2

[0033] The present invention also provides a novel fan motor, the novel fan motor 2 includes a novel stator tooth pole structure described in Embodiment 1, the novel fan motor 2 also includes a rotor 3, and the rotor 3 is equipped with Located outside the stator pole body 1 , the rotor 3 includes a hollow cylindrical permanent magnet 31 with a predetermined length, and the permanent magnet 31 is fixed inside a motor housing 32 on which fan blades are mounted.

[0034] The permanent magnet 31 is glued inside the motor housing 32, which can prevent the permanent magnet 31 from being thrown off under the action of centrifugal force, and can rotate around the stator core body 1 inside the motor housing 32 to improve the stability and performance of the structure. safety performance.

[0035] The outer diameter of the motor housing 32 is 19 mm, the thickness of the motor housing 32 is 0.35 mm, the outer diameter of the permanent magnet 31 is 18.3 mm, and the thickness of the perman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com