Revolving electrohydraulic serve rotatable in limited angles

An electro-hydraulic servo valve, limited angle technology, applied in the direction of servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve the problem of discontinuous opening of the valve port of the rotary valve, affecting the control effect, etc., to achieve manufacturing and assembly Convenience, flexible control, and simple control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

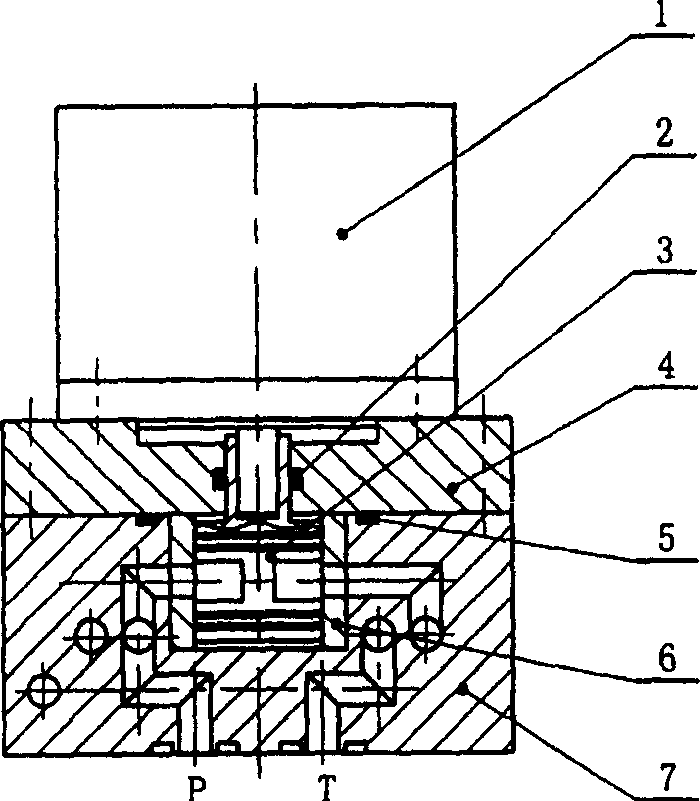

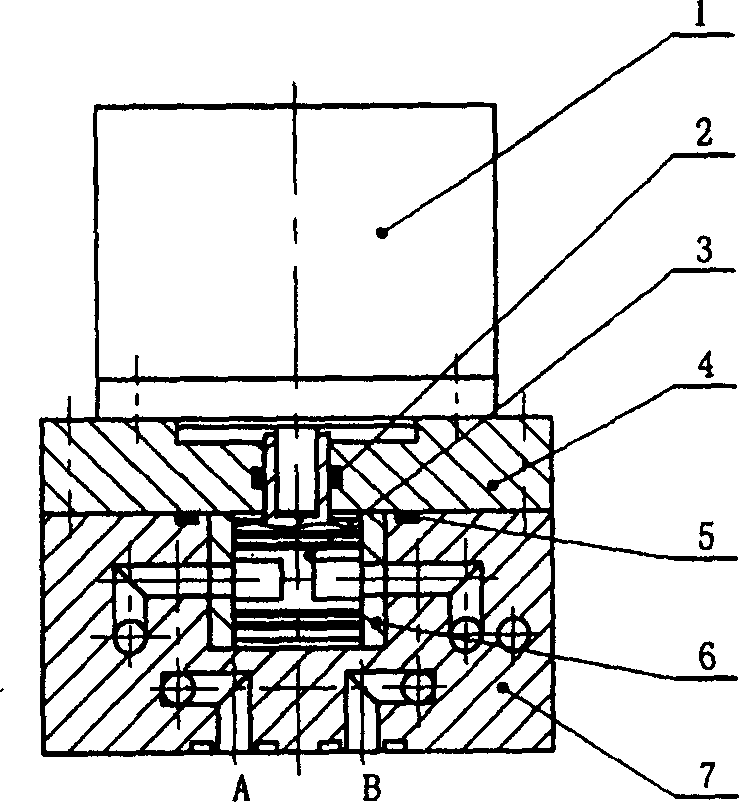

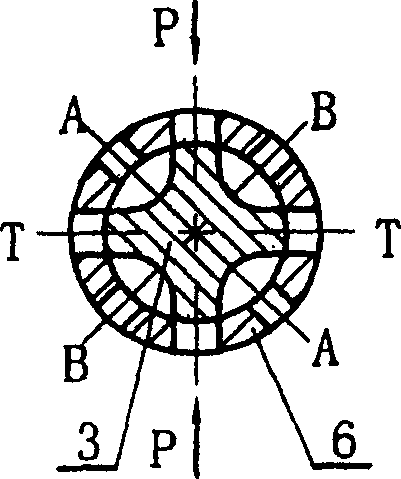

[0012] The present invention will be described in further detail below. see figure 1 , 2 , 3. The limited-angle rotary electro-hydraulic servo valve of the present invention is composed of a driving motor 1, a sealing ring 2, a valve core 3, an end cover 4, a sealing ring 5, a valve sleeve 6 and a valve body 7. The upper end surface of the valve body 7 has a cylindrical non-through inner cavity, and a tubular valve sleeve 6 is arranged in the inner cavity, which is closely matched with the inner cavity, and the height of the valve sleeve 6 is the same as the depth of the inner cavity. There are four special-shaped valve ports uniformly distributed along the circumference and with the same opening shape on the valve sleeve 6, wherein two valve ports symmetrical to the center of the circle are P ports, and the other two valve ports symmetrical to the center of the circle are T ports. Port P is the pressure oil port, and port T is the oil return port. There is a circular thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com