The electric arc spraying device

A technology of arc spraying and supplying device, which is applied in the direction of fusion spraying, metal material coating process, coating, etc., which can solve the problems of increased conveying resistance, limited guide tube length, inability to work efficiently, etc., to achieve arc spraying stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the invention will be described based on examples with reference to the drawings.

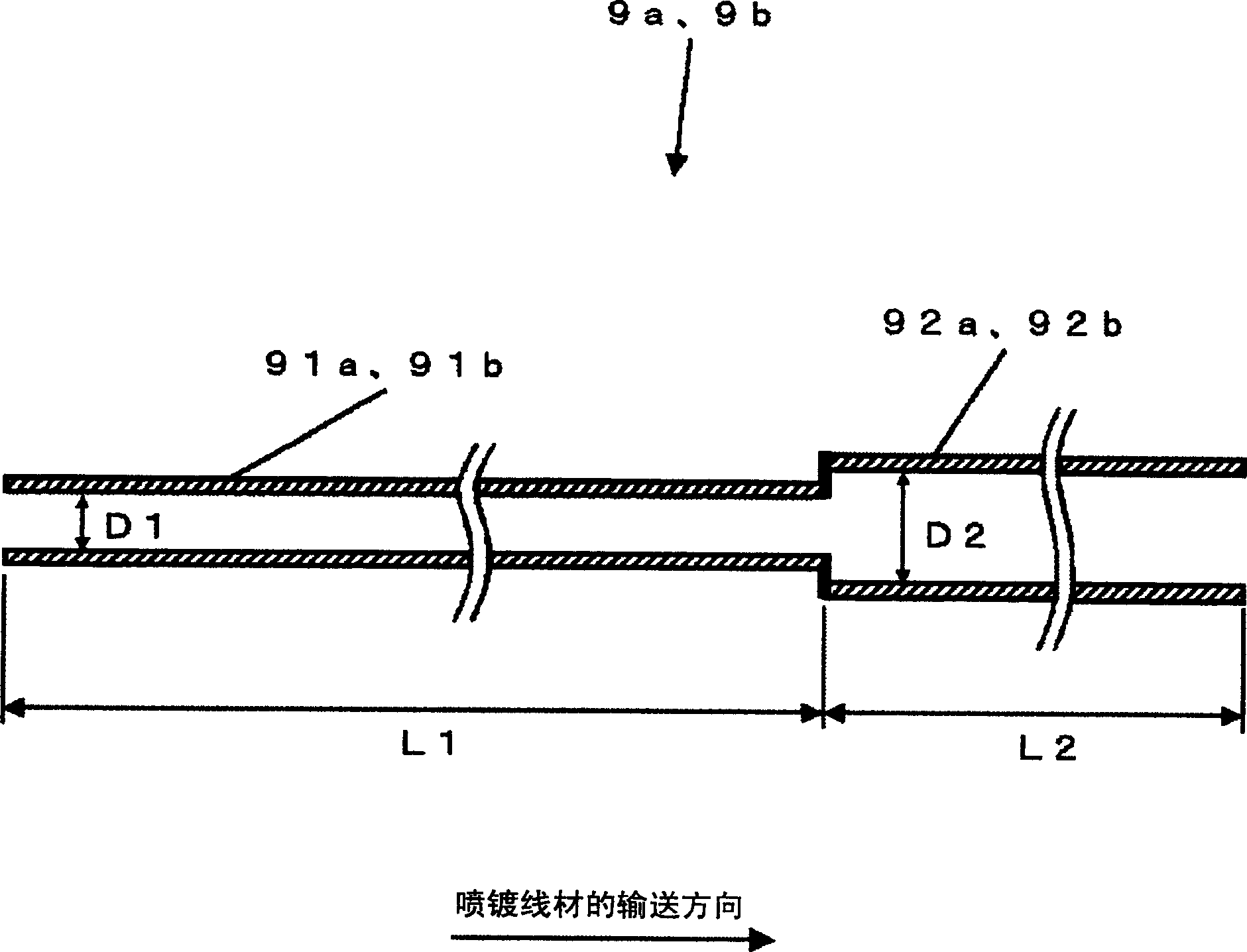

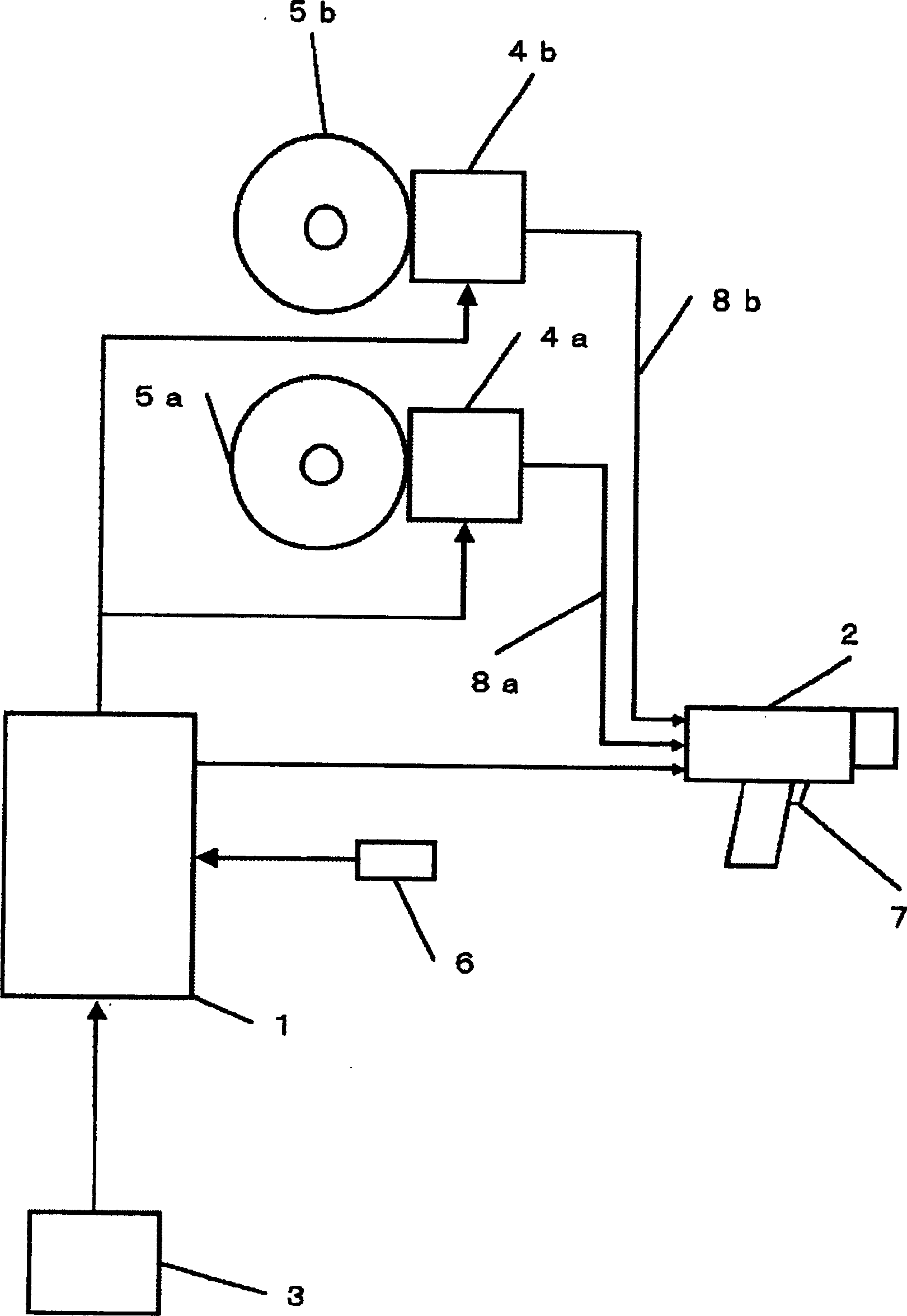

[0024] figure 1 It is a cross-sectional view of a guide pipe for conveying two sprayed wires between the wire supply device and the spray gun in the arc spraying apparatus of the present invention. In this figure, the guide tubes 9a, 9b are not used figure 2 The shown prior art guide tubes 8a, 8b are made of a flexible material that does not expand or contract in the axial or radial direction. will be from figure 2 The inner diameter D1 of the connection side of the two wire supply devices 4a, 4b shown in the predetermined length to the pushing side pipe 91a, 91b is made into a normal inner diameter with a small difference between the outer diameter of the sprayed wire rod and the inner diameter of the guide pipe. In addition, the inner diameter D2 of the drawing side pipes 92a, 92b from the tip of the pushing side pipes 91a, 91b to the connection side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com