Organic electroluminescent device and electronic apparatus

An electroluminescence device and electroluminescence technology, which are applied to electroluminescence light sources, instruments, electric light sources, etc., can solve the problems of only determining the position of the substrate surface direction, shortening life, and reducing conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 Embodiment approach

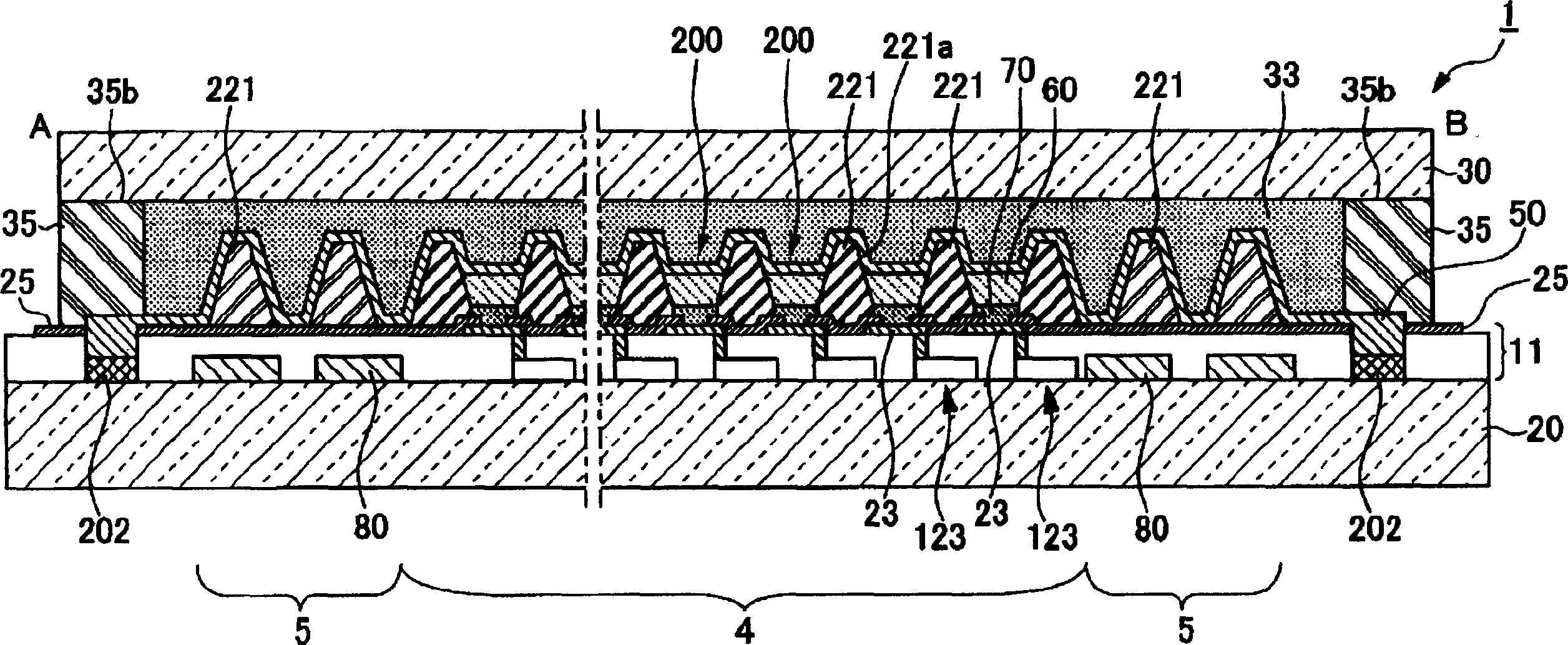

[0089] Refer to the following Figure 7A third embodiment of the present invention will be described. Figure 7 It is a partial cross-sectional configuration diagram showing an enlarged side end portion of the organic EL device according to the present embodiment. The organic EL device of this embodiment is characterized in that the contact portion of the protective substrate 30 and the spacer 35 is provided in an embedded structure, and other configurations are the same as those of the first embodiment above. therefore, Figure 7 Among the constituent elements shown, pay Figure 1 to Figure 5 Components with the same symbols are the same components.

[0090] Such as Figure 7 As shown, in the organic EL device of this embodiment, the outer end portion of the protective substrate 30 on the element substrate 20 side is provided with a notch portion 30a, and the inner side of the upper end portion of the spacer 35 erected on the element substrate 20 is opposite to the The c...

no. 4 Embodiment approach

[0092] Refer to the following Figure 8 A fourth embodiment of the present invention will be described. Figure 8 It is an enlarged partial cross-sectional configuration diagram of the outer end portion of the organic EL device according to the present embodiment. The organic EL device of this embodiment is characterized in that the contact portion between the protective substrate 30 and the spacer 35 is provided in an embedded structure, and other configurations are the same as those of the first embodiment above. therefore, Figure 8 Among the constituent elements shown, pay Figure 1 to Figure 5 Components with the same symbols in are the same components.

[0093] Such as Figure 8 As shown, in the organic EL device of the present embodiment, a notch 35c is provided inside the upper end portion of the spacer 35 standing upright on the element substrate 20 to protect the edge portion of the element substrate 20 side of the substrate 30 against the The cutout portion 35c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com