Leather fiber separating machine

A leather fiber and separator technology, applied in fiber treatment, decomposition of fiber-containing substances, decomposition and restoration of textiles, etc., to achieve the effect of easy operation, beneficial waste utilization, and complex equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

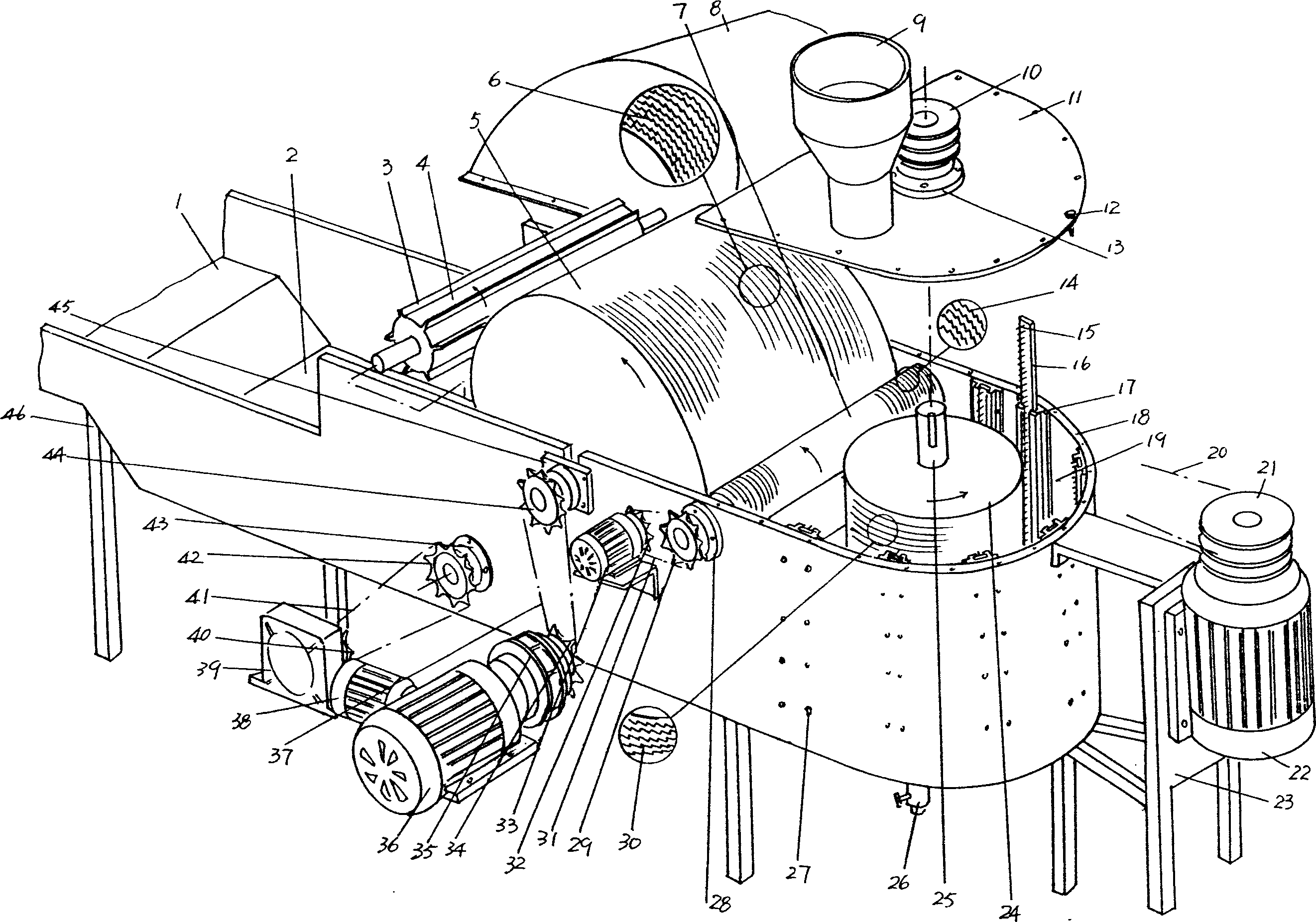

[0017] Please refer to the accompanying drawings, a cylindrical body 18 is provided, the cylindrical body 18 is like a boat shape, more specifically, it is close to a horseshoe shape as a whole, and its front end is processed into a semicircle. It is equipped with a cylinder cover 11 that can ensure a good cover fit with the front end of the semicircular cylinder body, and the cylinder cover 11 is screwed with the front end of the cylinder body 18 by screws 12 . The reason why the position of the feed opening is selected on the cylinder cover 11 is because it can better correspond to the fiber opening mechanism, the feed opening can be directly opened as a through hole on the cylinder cover 11, and is equipped with a Hole cover; also can adopt the mode of feeding hopper 9 shown in the figure, the applicant thinks that the mode of selecting feeding hopper 9 no matter is for feeding, or prevents the throwing out of the water in the cylinder cavity and is all favorable.

[0018] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com