Method and device for eliminating yarn flaws

A yarn and defect technology, applied in the field of textile machines, can solve problems such as the deterioration of yarn quality, and achieve the effect of accurate unwinding length and economical removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

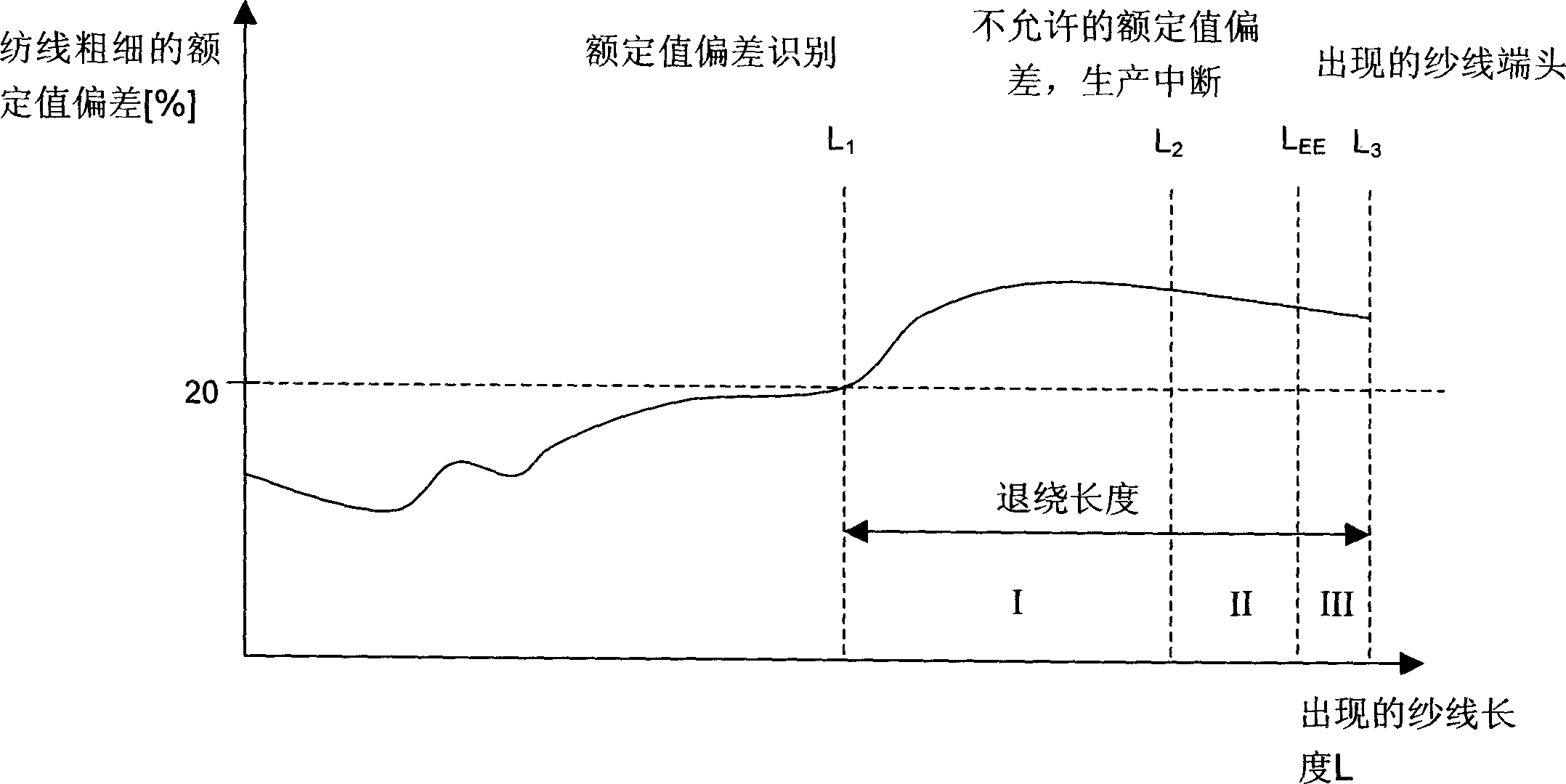

[0032] figure 1 Describes the percentage deviation from the nominal value that occurs over the yarn length. In the depicted legend, a tolerance range is depicted with dashed lines. The dotted line indicates the maximum permissible percentage deviation of 20% from the nominal value. Below this dotted line, the yarn thickness can be shifted up to the length L 1 , that is, only within the allowed range. In the resulting yarn length L 1 On the contrary, the yarn thickness exceeds the allowable tolerance range, and the yarn emerging from this time is potentially defective due to the reasons mentioned above. length up to L 2 Afterwards, deviations from the nominal value are not permitted and yarn production is stopped. from L 1 to L 2 The thread length that appears is the first thread length I. The length that exceeds the allowable tolerance value can be pre-determined by a function, but the function at this position cannot be further considered. In principle, it can be ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com