Apparatus and method for detecting sheet-like material

A sheet material and image detection technology, which is applied in the direction of measuring devices, material analysis, and material analysis through optical means, can solve problems such as errors, inability to detect color printing, and extremely sensitive use environments, so as to simplify the structure and reduce Calculation and storage capacity, and the effect of improving the operation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

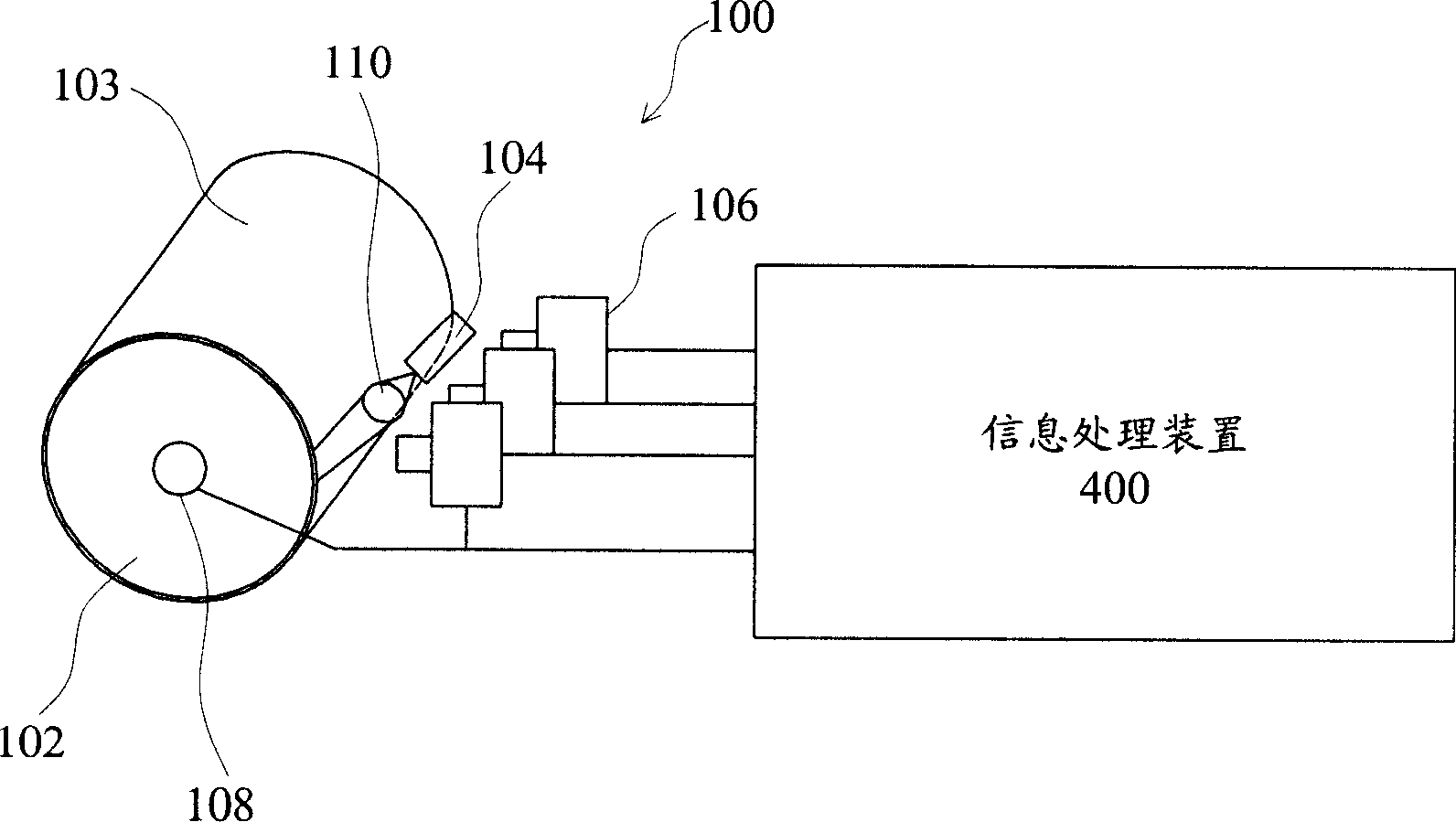

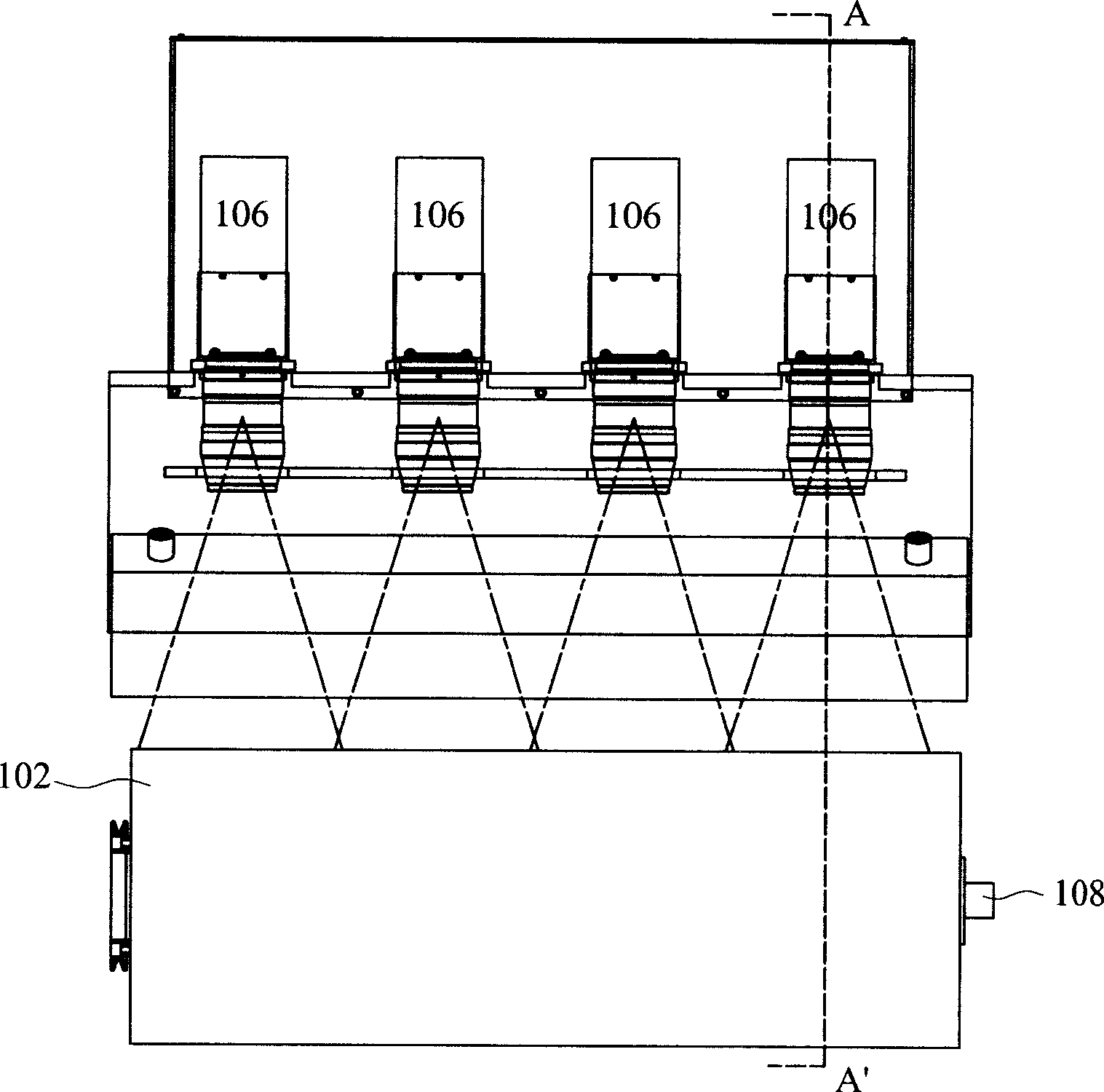

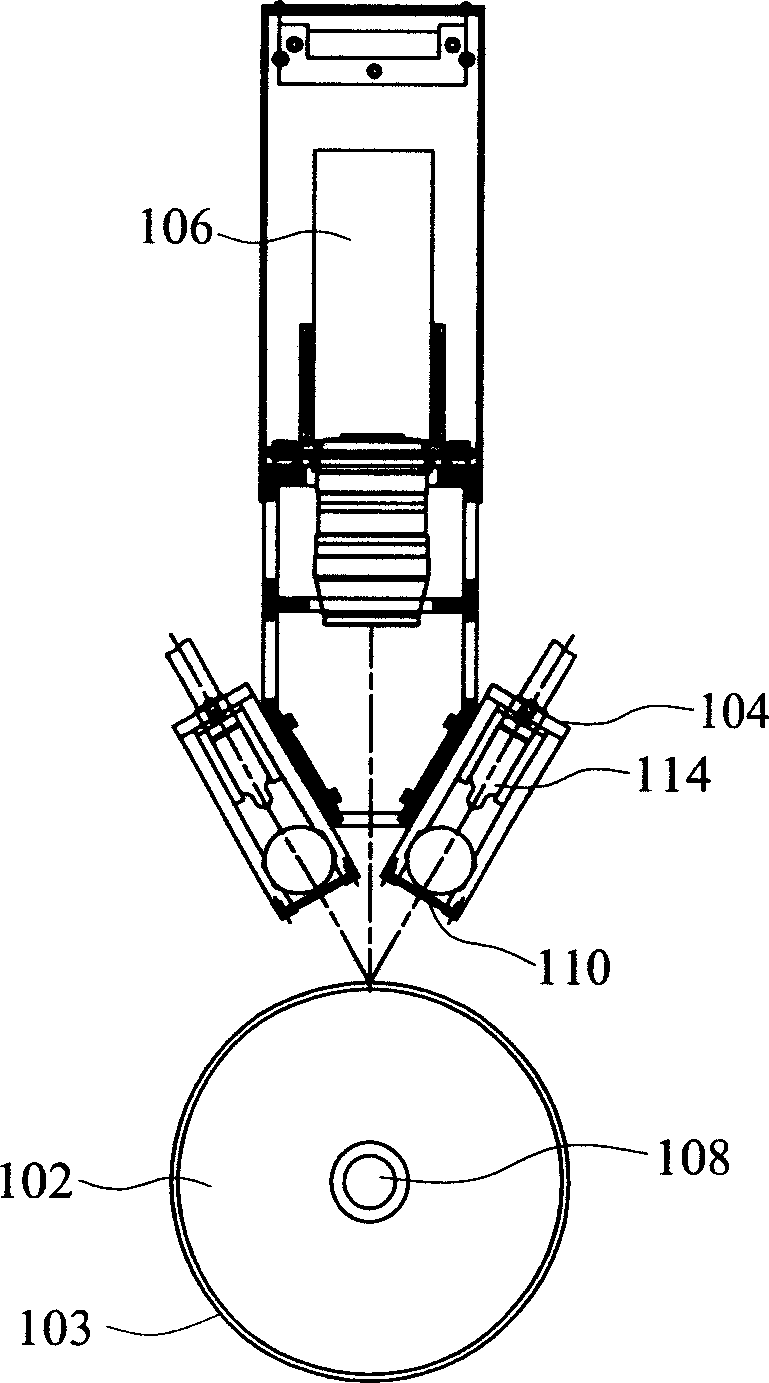

[0034] The invention will now be described with reference to the accompanying drawings. figure 1 is a structural diagram of the detection device according to the present invention. The detection device 100 includes a conveying device 102 for carrying and transporting a sheet material 103 (not shown); an illuminating device 104 for irradiating light onto the sheet material; a receiving device 106 for receiving the material from the sheet The light diffused or reflected by the shape material, and convert the received light into a corresponding detection image, which is a color image; the information processing device 400 is used to collect and process the detection image, and compare the detection image with the template , in order to detect the color printing quality of sheet materials. The template establishment process is as follows. Before the detection, a template needs to be established. Through visual observation, select a certain number of good products, use the device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com