Lift running safety recall estimating system

A technology for evaluating system and elevator operation, which is applied in transportation, packaging, elevators, etc. It can solve the problems of untimely monitoring, labor-intensive, and inability to observe the elevator running status in real time, so as to achieve standardization and increase the degree of normalization, and avoid the influence of human factors , thoughtful and easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The system structure and working principle of the present invention will be described in detail below according to the accompanying drawings.

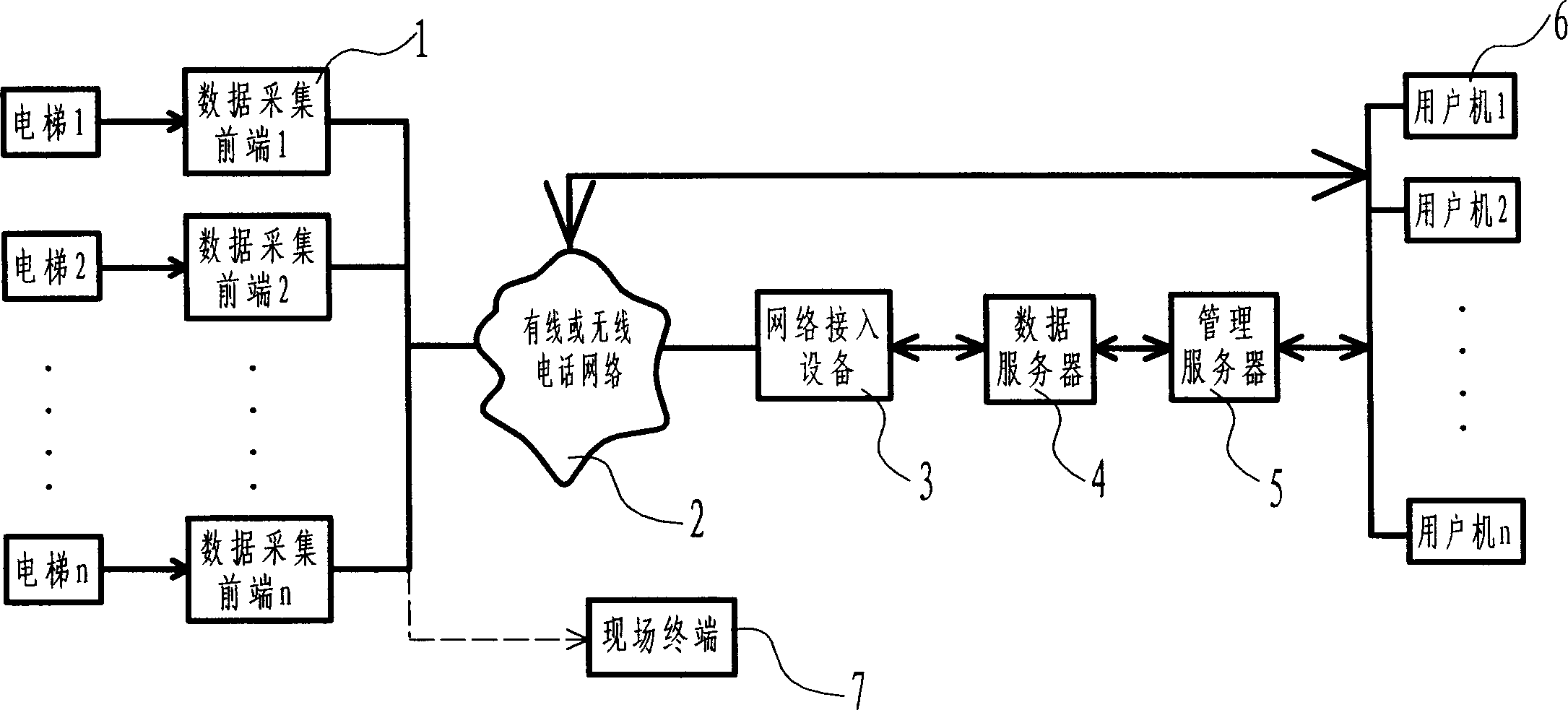

[0033] see figure 1 , the present invention can set up n data acquisition front-ends (hereinafter referred to as front-ends) according to the number n (n=1, 2, 3...n) of elevators that need to be monitored, and these n front-ends 1 pass wired or wireless telephone network 2 and network The access device 3 is connected to the data server 4, the data server 4 is connected to the user management server 5, and n user terminals 6 are connected to the data server 4 through the user management server 5 to form a local area network. Front-end 1 carries out multi-point monitoring and collection of fault information to the corresponding elevator, and data server 4 carries out regular cycle extraction to the fault information collected by multiple front-ends, and stores in the historical fault information database, and user terminal machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com