Fire-proof mask and special expansion material of its radiating fin

A technology of intumescent material and fireproof cover, which is applied in the field of special expansion material for fireproof cover and its heat sink, can solve problems such as flame extinguishing, and achieve the effect of good expansion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

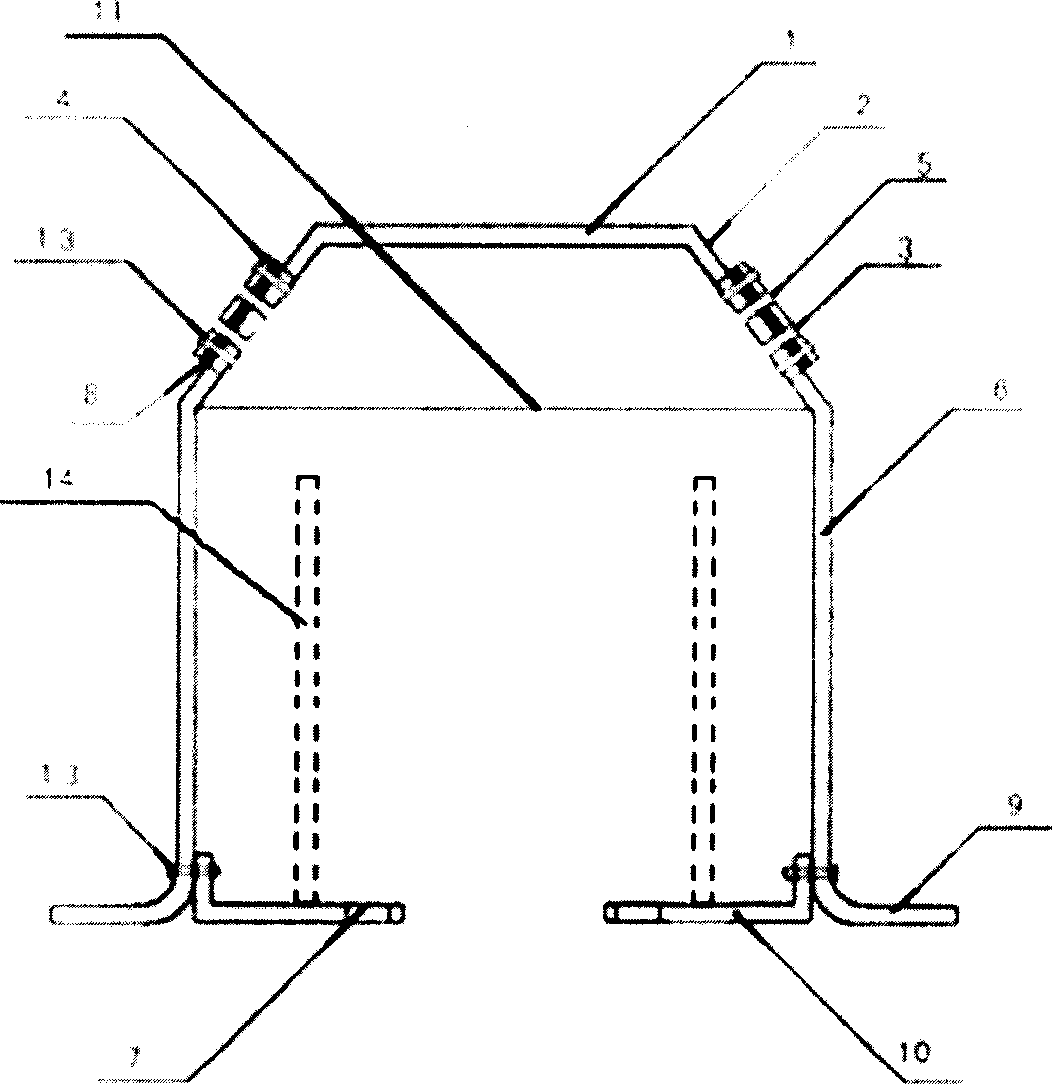

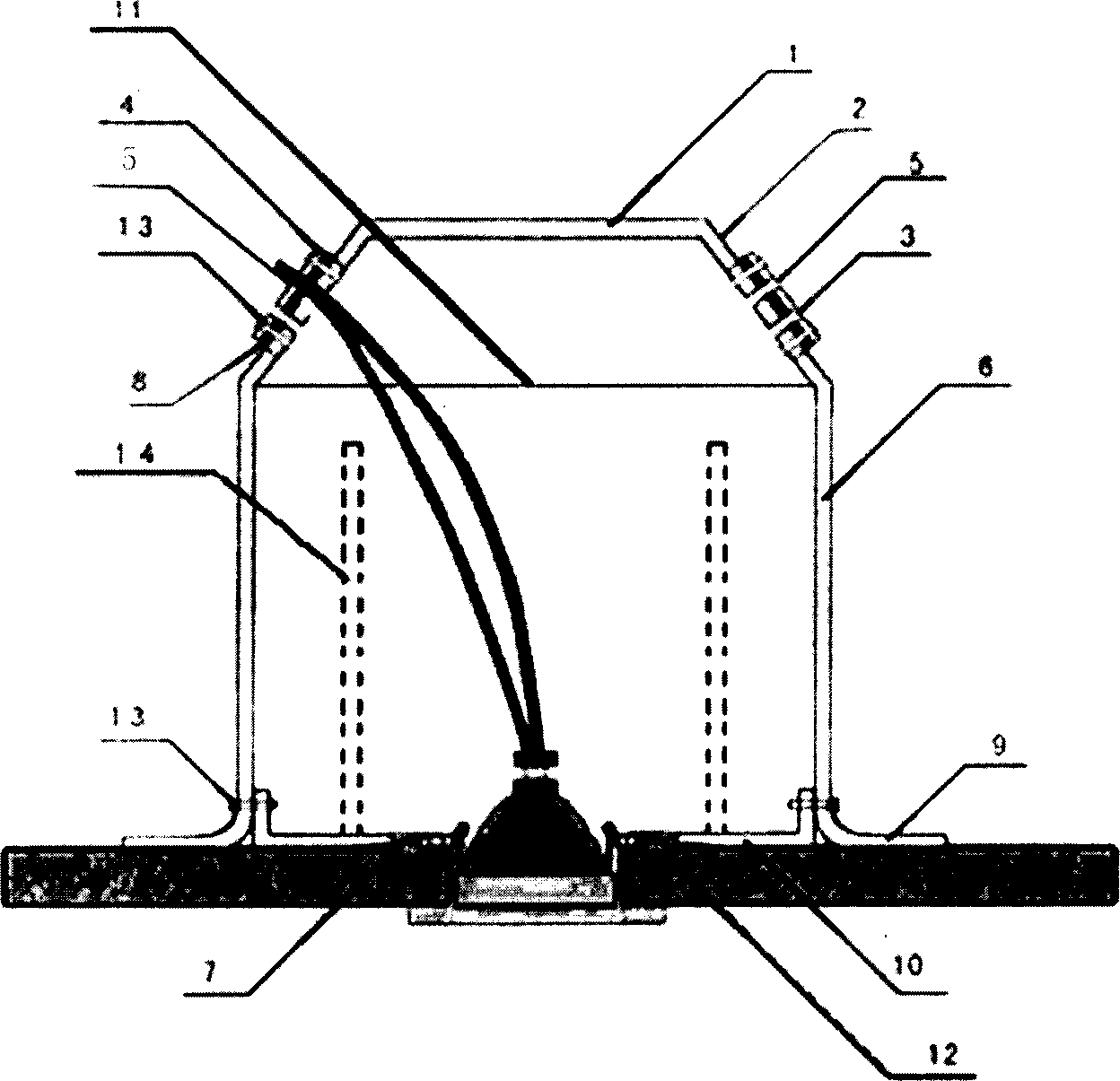

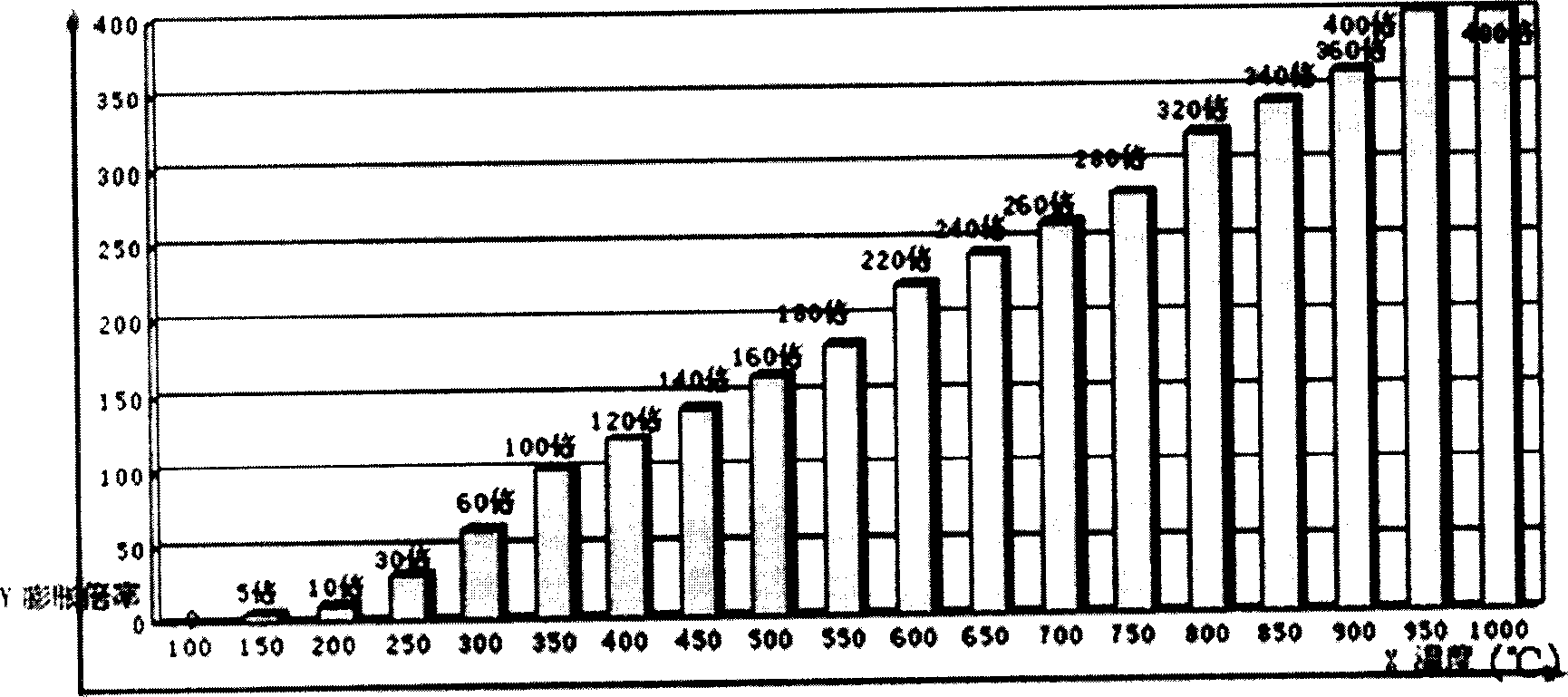

[0040] Such as figure 1 , figure 2 A kind of fireproof cover shown, it comprises cover top 1, hypotenuse 2, cover surround 6 and cover skirt 9, is provided with the cooling fin that is made of lower expansion material sheet 8 and upper layer ceramic fiber paper 4 on the hypotenuse, this The heat sink is installed on the hypotenuse by rivets 13, and the heat sink is provided with a plurality of air holes 3, one of which is a threading hole 5. The inside of the cover enclosure is provided with an inner cover support frame 14, and the cover top, beveled sides, cover enclosure and cover skirt are sewn from glass fiber cloth material with a fireproof paint layer on one side and a temperature resistance > 750°C. It can be seen that there is a sewing line 11) between the hypotenuse 2 and the enclosure 6 to make it resistant to temperatures >750° C. and form a closed cylinder. Two metal mounting brackets 10 are installed on the two ends of the fireproof cover by rivets 13, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com