Operation vehicle

A technology for working vehicles and continuously variable speed change devices, which is applied in the fields of agriculture, vehicle parts, agricultural machinery and implements to achieve good detection accuracy, maintain detection accuracy, and maintain speed change accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

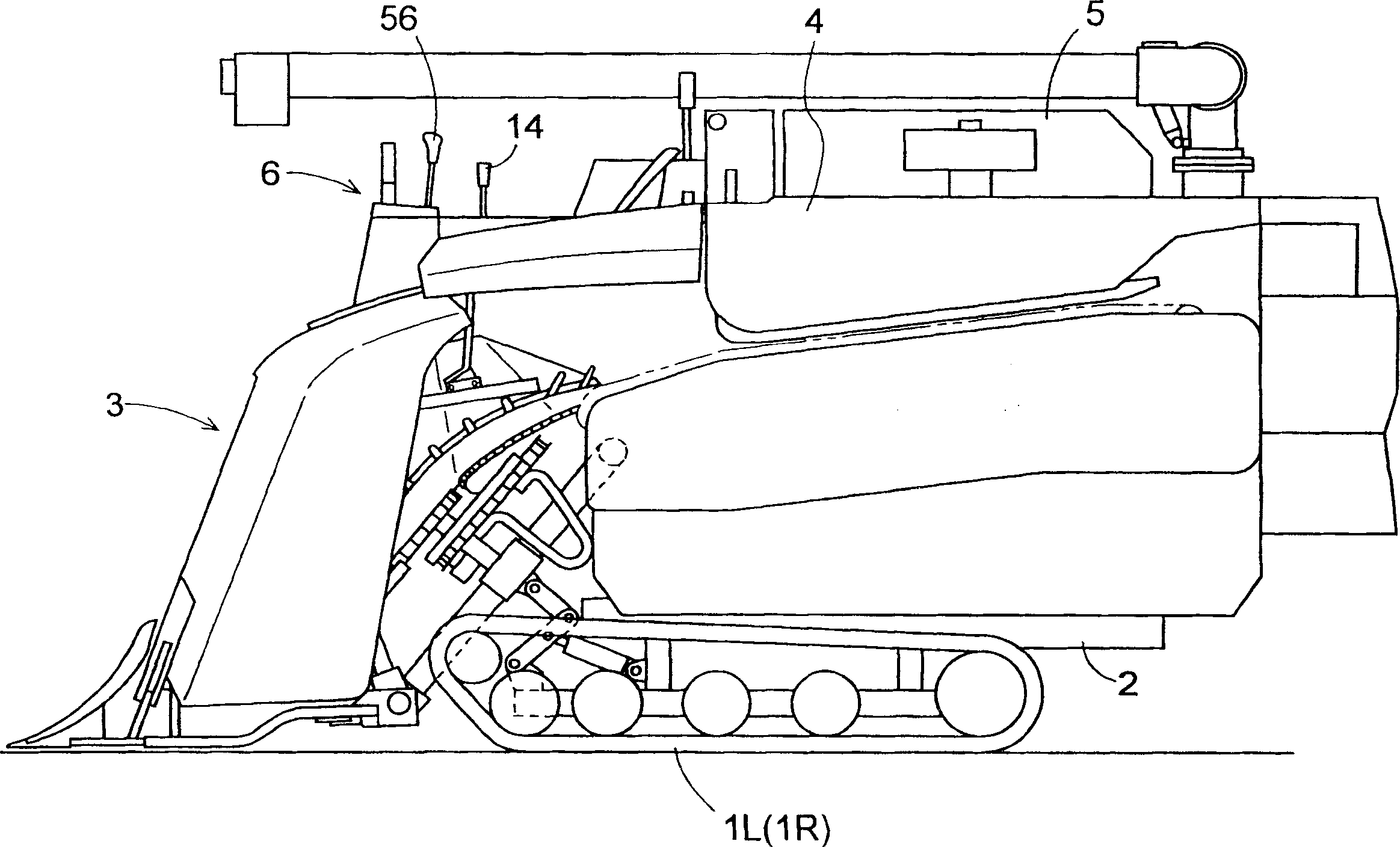

[0049] Hereinafter, a suitable embodiment of the work vehicle of the present invention will be described with reference to the drawings using a combine as an example of one type of agricultural work machine.

[0050] figure 1 Shows the overall side view of the combine harvester. The combine harvester is constituted by a reaping conveyer 3 that reaps planted grain stalks and conveys them rearwardly connected to the front portion of a traveling body 2 that is driven by a pair of left and right crawler-type traveling devices 1R and 1L. On this traveling body 2, the threshing device 4 which receives the harvested grain stalk from the reaping conveyance device 3, and performs threshing and sorting process, and the grain container 5 which stores the grain from the threshing device 4 are mounted. Riding and driving portion 6 is formed in front of grain container 5 .

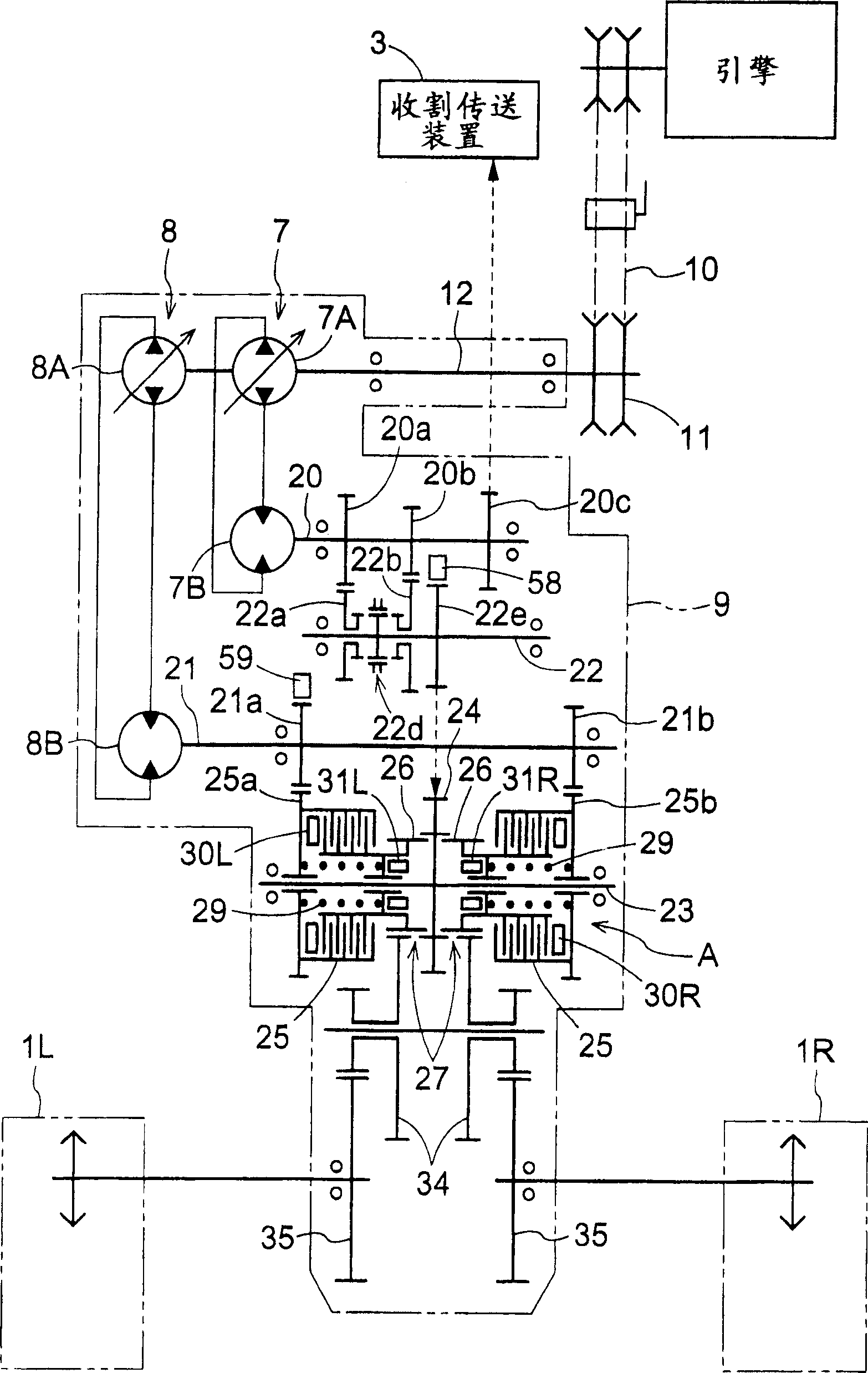

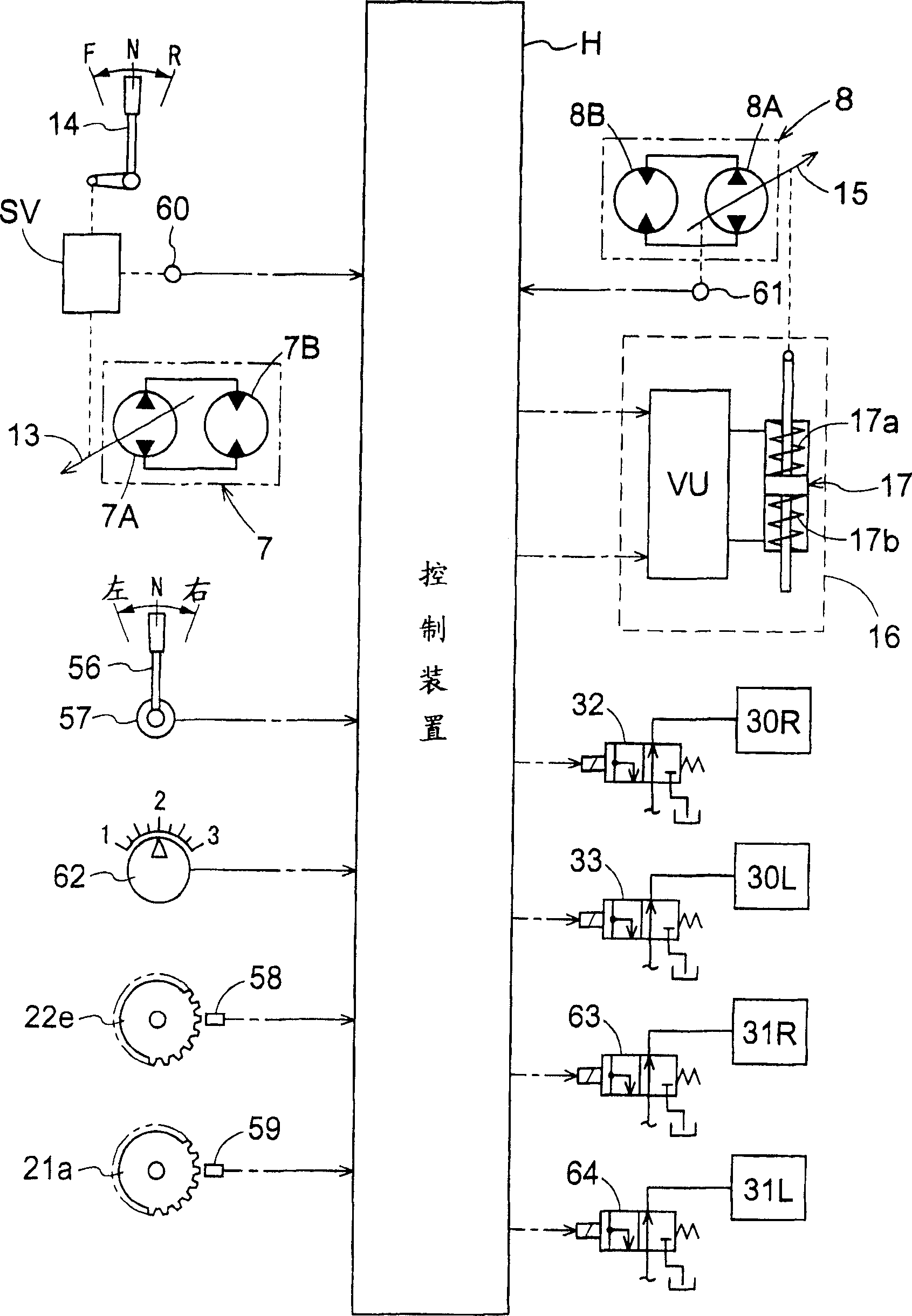

[0051] Such as figure 2 and image 3 As shown, the drive train of the combine harvester has: a straight continuo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com