Method of inspecting an mura defect in a pattern and apparatus used for the same

A defect inspection and pattern technology, applied in the field of uneven pattern defect inspection devices, can solve the problems of deviation in inspection results, inability to detect with high precision, and difficulty in showing uneven defects, and achieve the effect of high precision detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

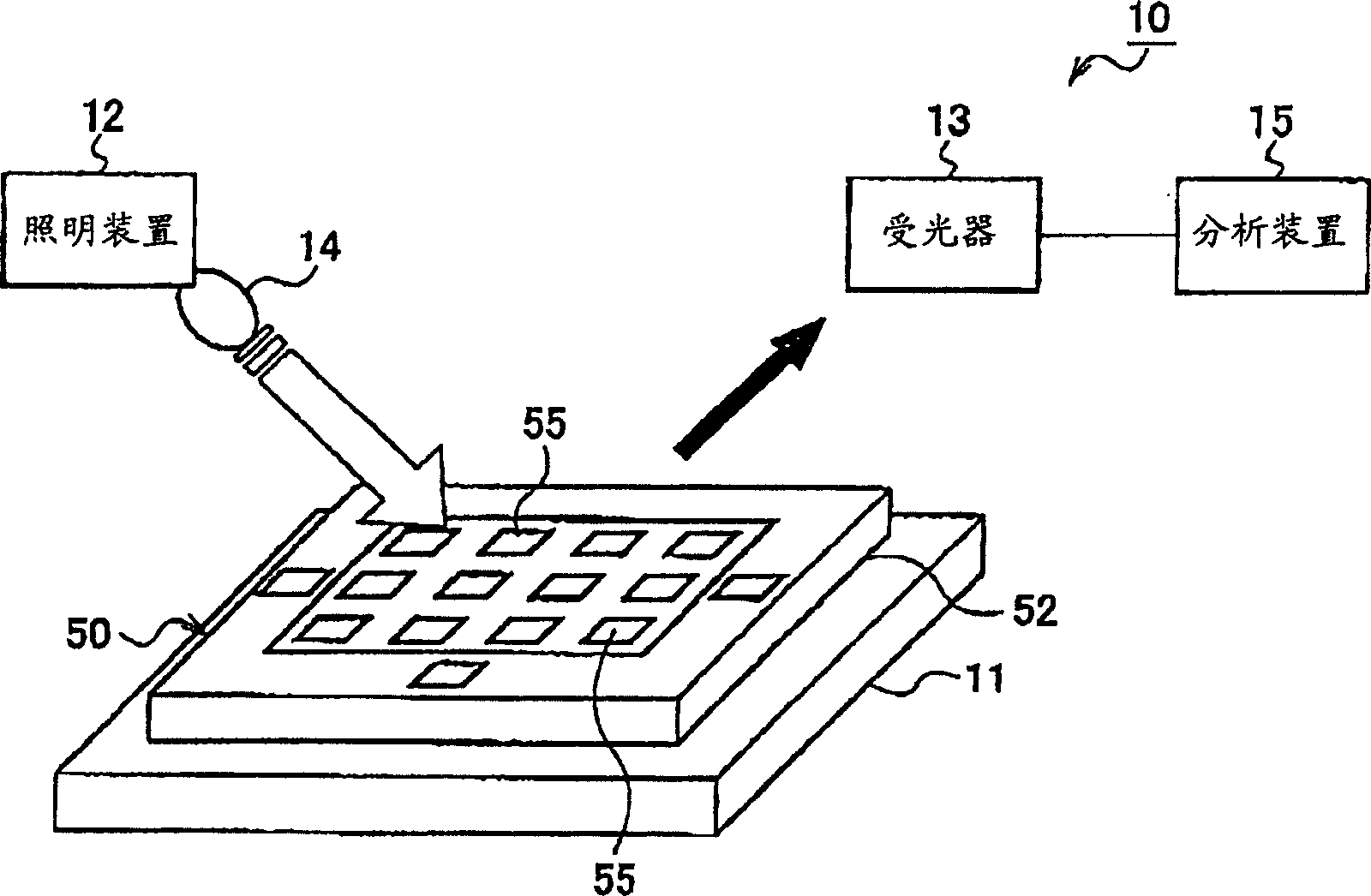

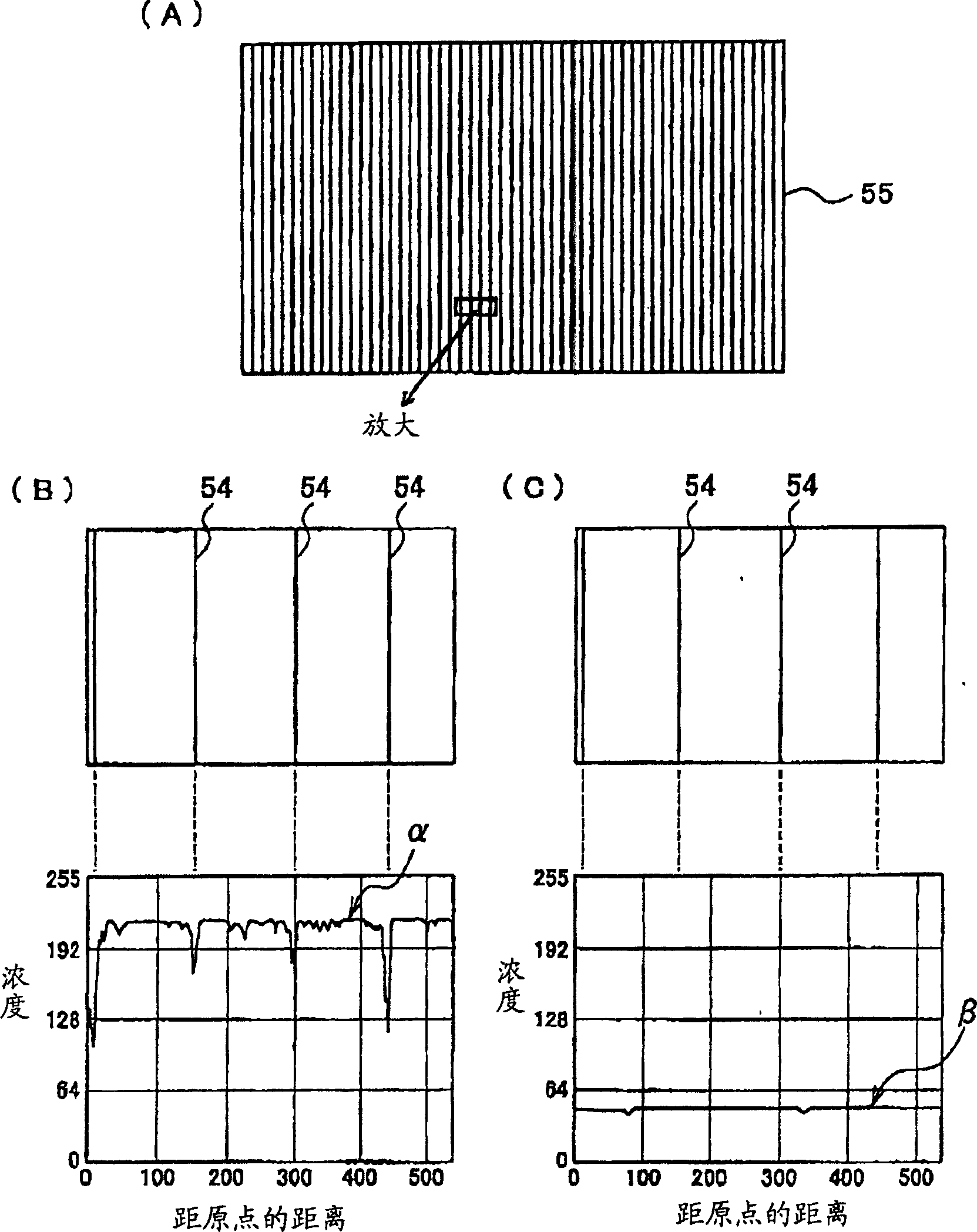

[0054] [B] Second embodiment ( Figure 5 )

[0055] Figure 5 It is a perspective view showing a second embodiment of the pattern uneven defect inspection device of the present invention. In this second embodiment, the same reference numerals are attached to the same parts as those in the first embodiment described above, and description thereof will be omitted.

[0056]In the uneven defect inspection device 20 according to the second embodiment, the illuminating device 12 is disposed below the photomask 50 . Therefore, the photoreceiver 13 receives the transmitted light between the repeating patterns 51 in the chip 55 of the photomask 50 irradiated from the illuminating device 12 , especially the diffracted light diffracted at the edge of the unit pattern 55 in the transmitted light. , and converted into photometric data.

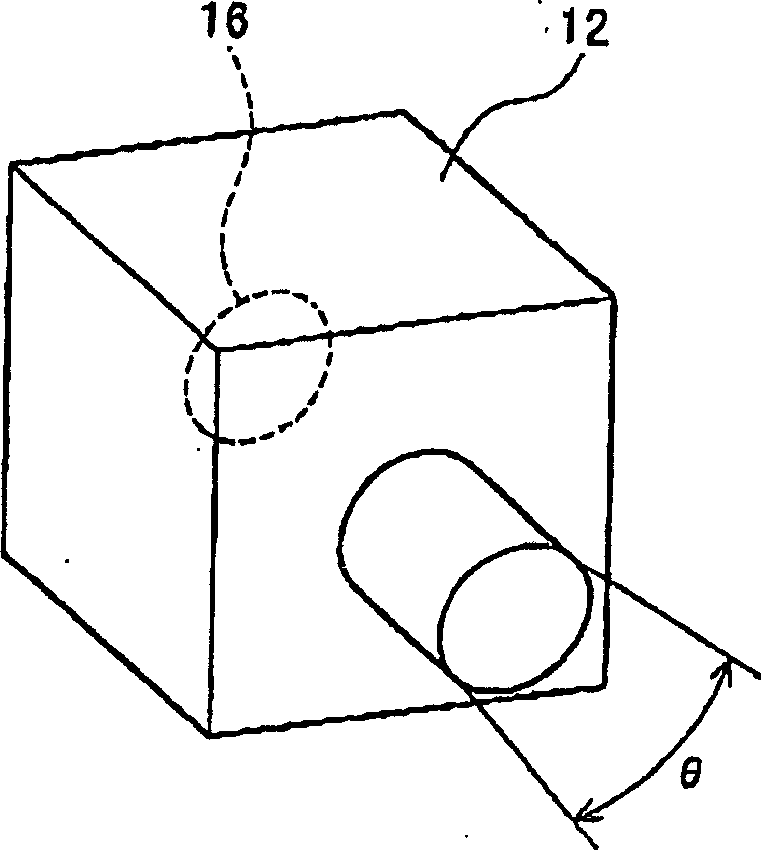

[0057] In this second embodiment, the illuminating device 12 directs the light emitted from the illuminating light source 16 with a directionality clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com