Connector PIN height measuring device and using method thereof

A height measurement device and connector technology, which is applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of increased inspection costs and expensive laser scanners, and achieve reduced inspection costs, strong copy compatibility, and the number of components little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment mainly introduces the basic composition and connection relationship of a connector PIN pin height measuring device of the present invention.

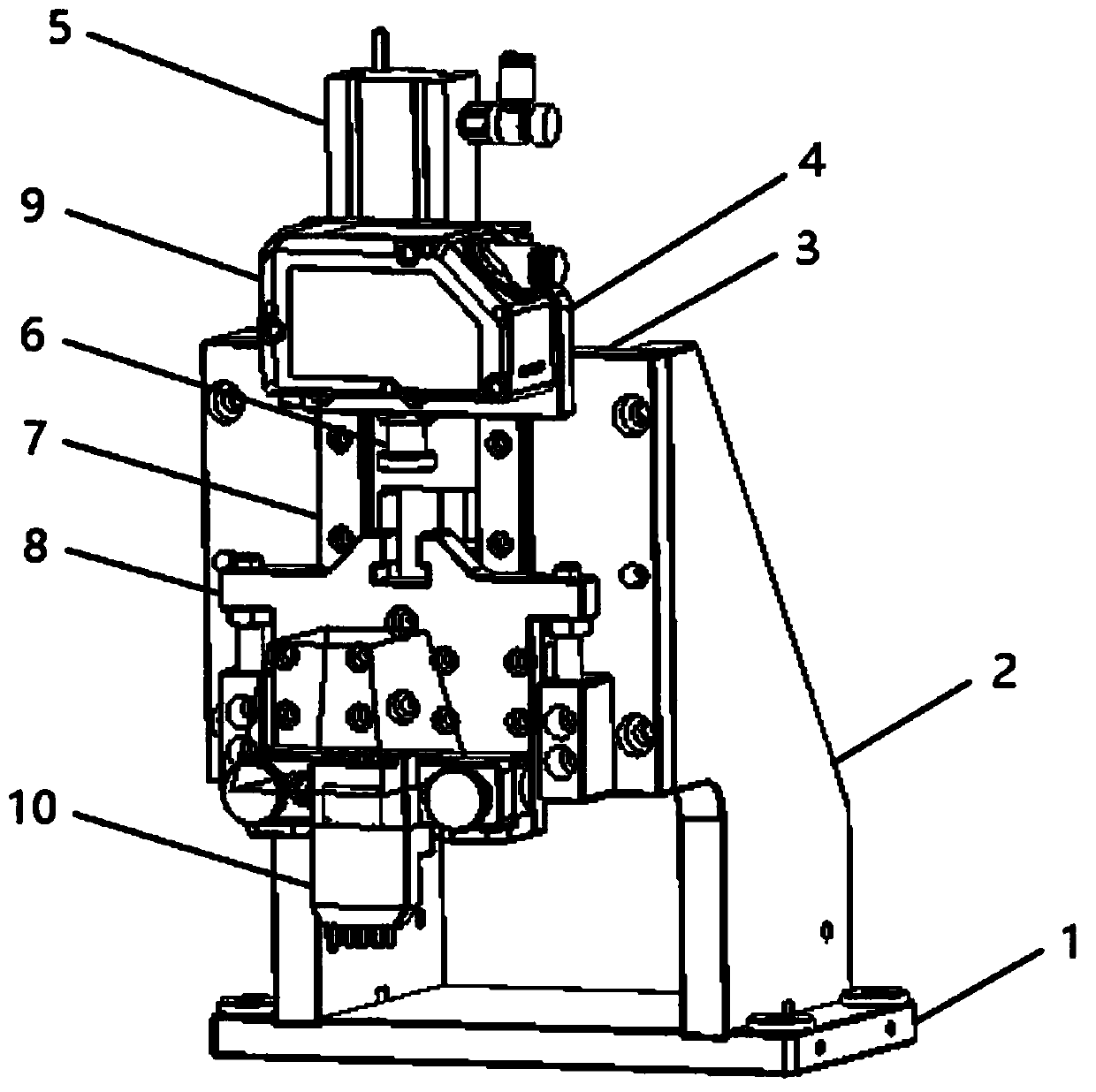

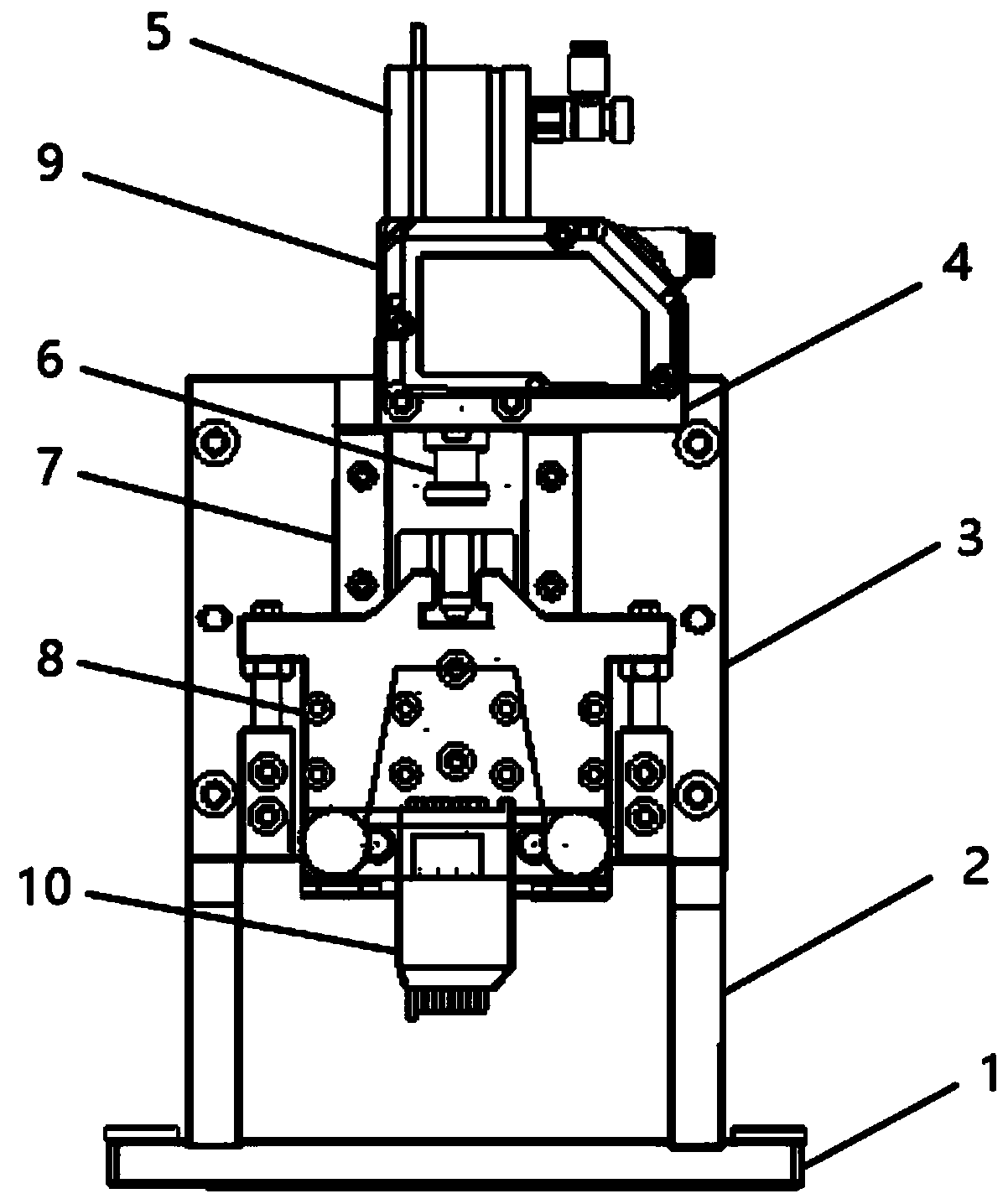

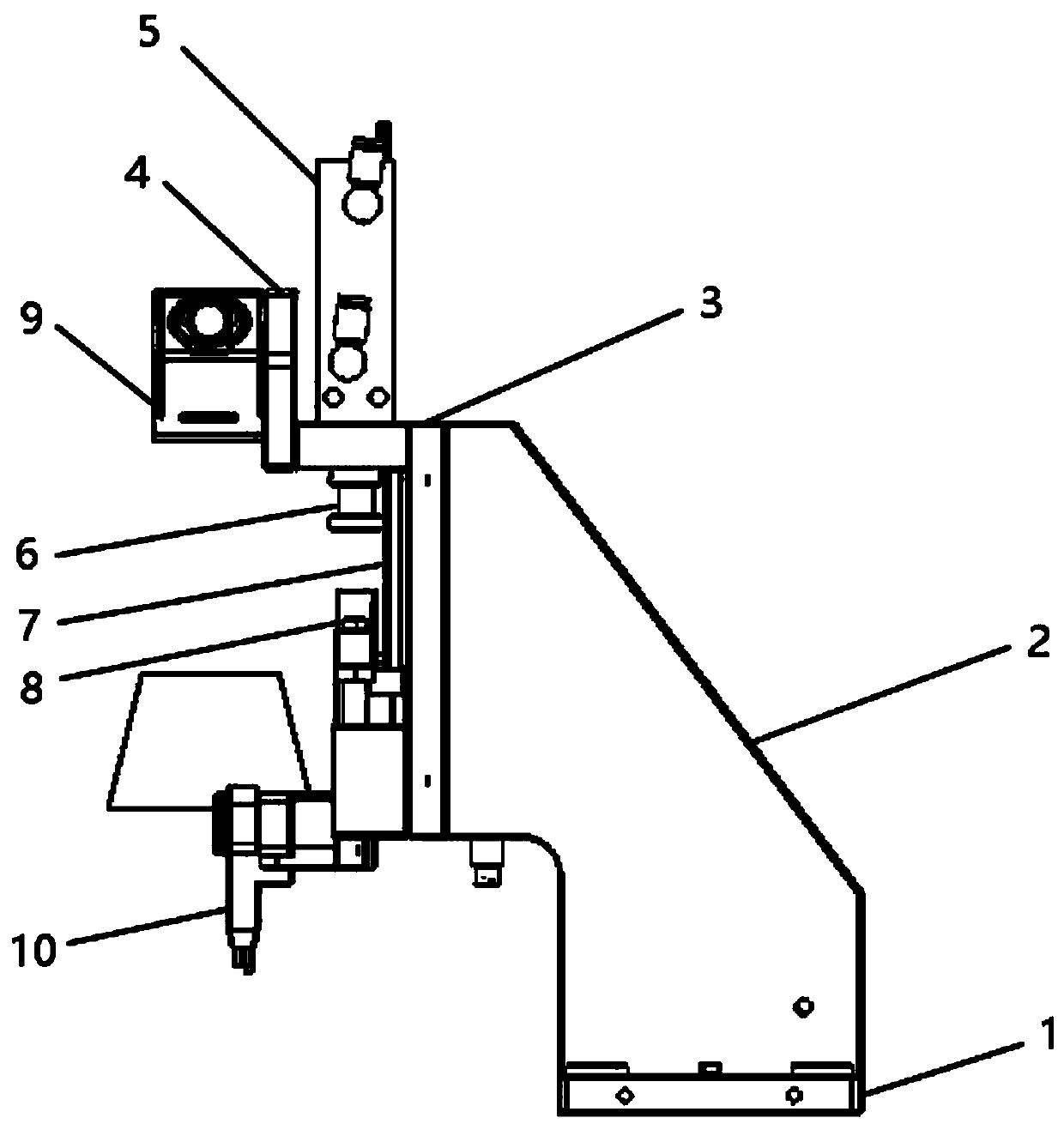

[0047] like figure 1 As shown in , it shows a perspective view of a connector PIN pin height measuring device; as figure 2 As shown, it shows a front view of a connector PIN pin height measuring device; as image 3 As shown in , it shows a right side view of a connector PIN pin height measuring device.

[0048] combine figure 1 , 2 As shown in , 3, a connector PIN pin height measuring device provided by the embodiment of the present application, the device includes a support unit, a power unit and a detection unit, and the structure of the support unit is a bracket with a base 1 for Carrying a detection unit and a power unit, the detection unit and the power unit are located on the bracket, the power unit is connected to the bracket to provide power for the detection unit, and the detection unit is connected ...

Embodiment 2

[0059] On the basis of Embodiment 1, this embodiment further proposes a method for using a connector PIN pin height measuring device. The same technical features and technical descriptions as Embodiment 1 will not be repeated in this embodiment.

[0060] combine figure 1 , 4 As shown, the method of using the connector PIN pin height measuring device is specifically:

[0061]Step 1: Integrate the connector PIN needle height measuring device into the production line for processing connectors with PIN needles, and the position of the height measuring device is in the downstream area of the production line relative to the processing device for connectors with PIN needles;

[0062] Step 2: Before each PIN needle detection, supply air to the feed cylinder 5 to press it down. As the pressure in the cylinder gradually increases, the piston rod and the floating joint 6 will move downward together. Under the action of the thrust of the floating joint 6, the sub-carrier 8 slides alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com