Frame structure for back-light module

A frame structure and backlight module technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as restrictions, discounted fixed effects, and large intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

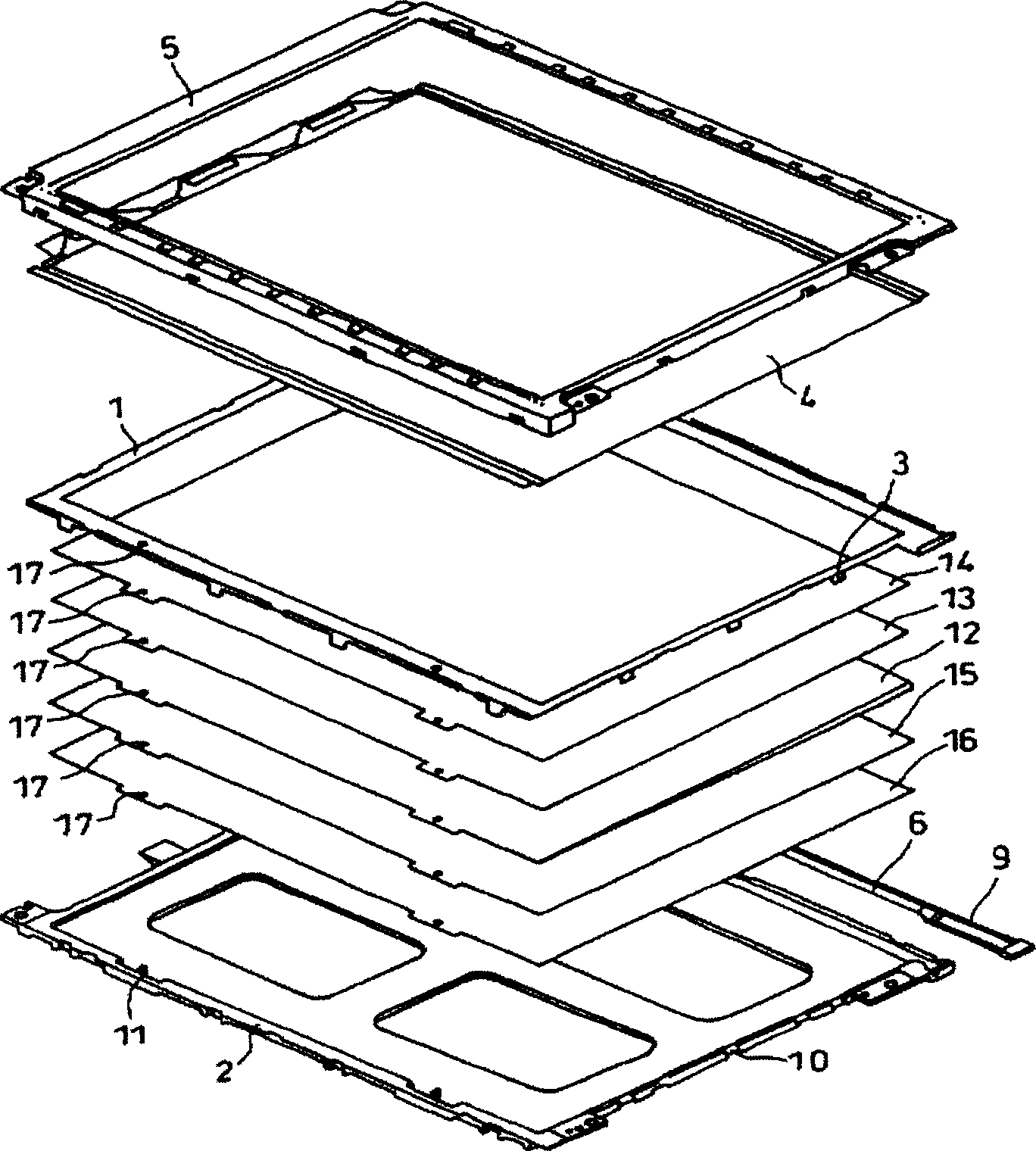

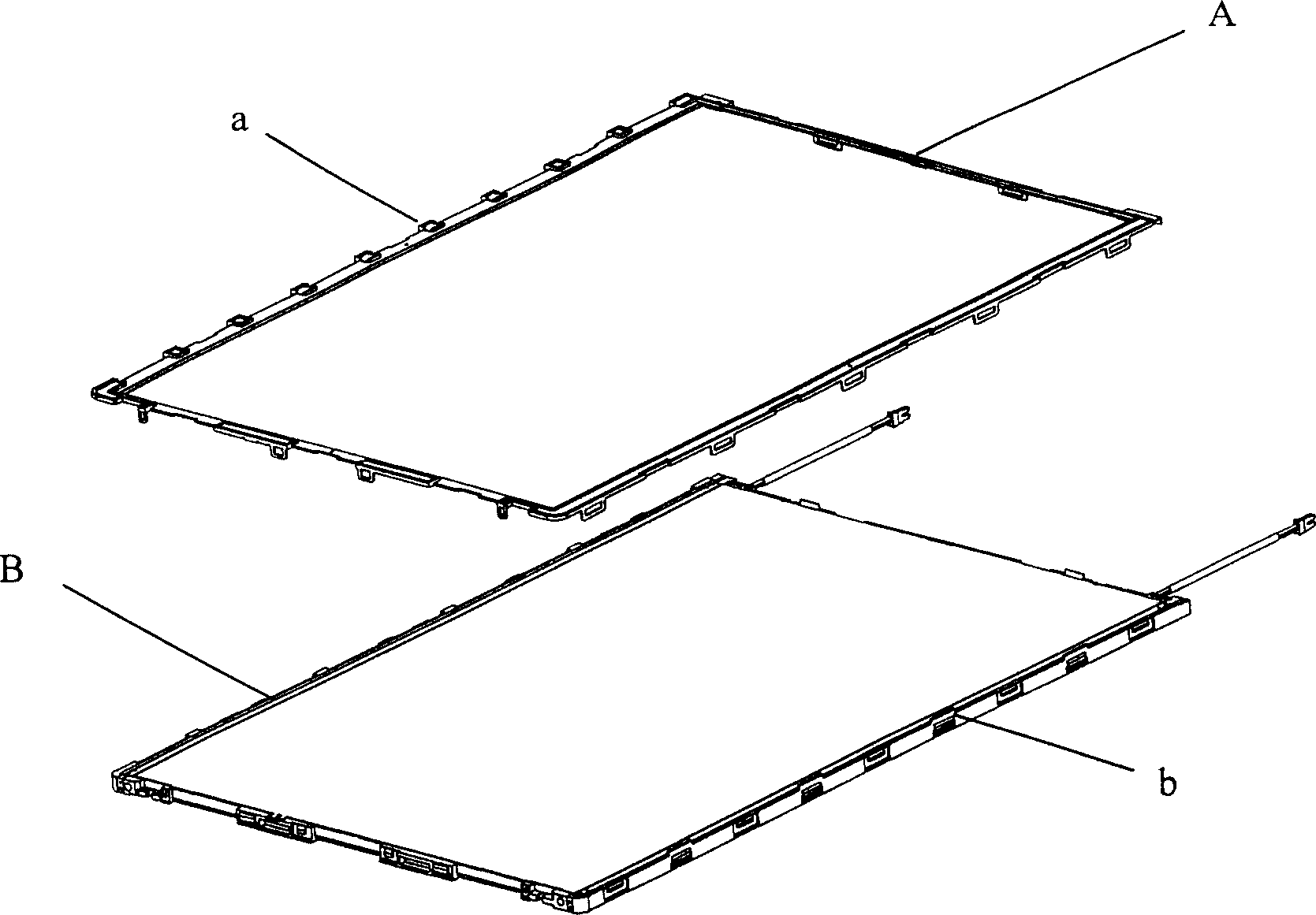

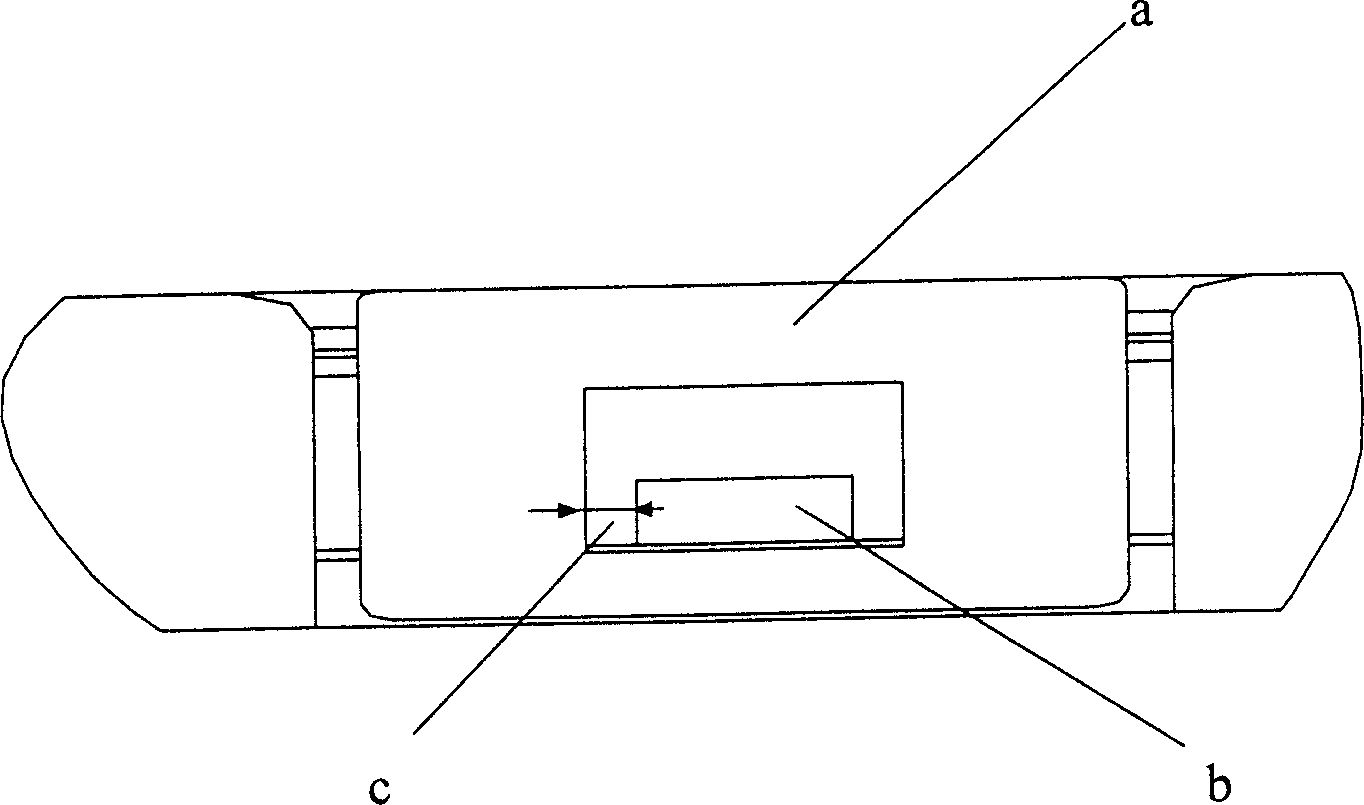

[0019] First, see Figure 4 . Figure 4 It is an exploded view showing the structure of the backlight module 20 utilizing the new frame structure of a preferred embodiment of the present invention. As shown in the figure, the backlight module is mainly composed of a plastic upper fixing frame 21, an upper diffusion plate 22, a light enhancement film 23, a lower diffusion plate 24, a light guide plate 25, a light source group and a metal or plastic lower fixing frame. The frame 26 is assembled sequentially from top to bottom; where the above-mentioned backlight module assembly is completely fixed by using the upper fixing frame and the lower fixing frame to achieve integration. The upper fixing frame has a fitting element that simultaneously restricts lateral movement and longitudinal movement, and the lower fixing frame has a corresponding fitting member that cooperates with the fitting element. For the specific structure of the fitting element and the corresponding fitting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com