Flexible induction wire for radar and manufacturing method thereof

A wire and flexible technology, applied in the field of flexible induction wires, can solve the problems of short service life, frequent replacement and low power of wires, and achieve the effect of ensuring tensile strength, reducing overall quality and high modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

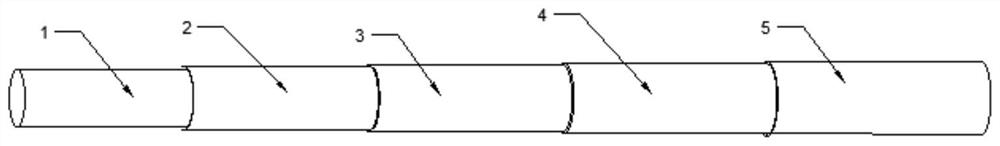

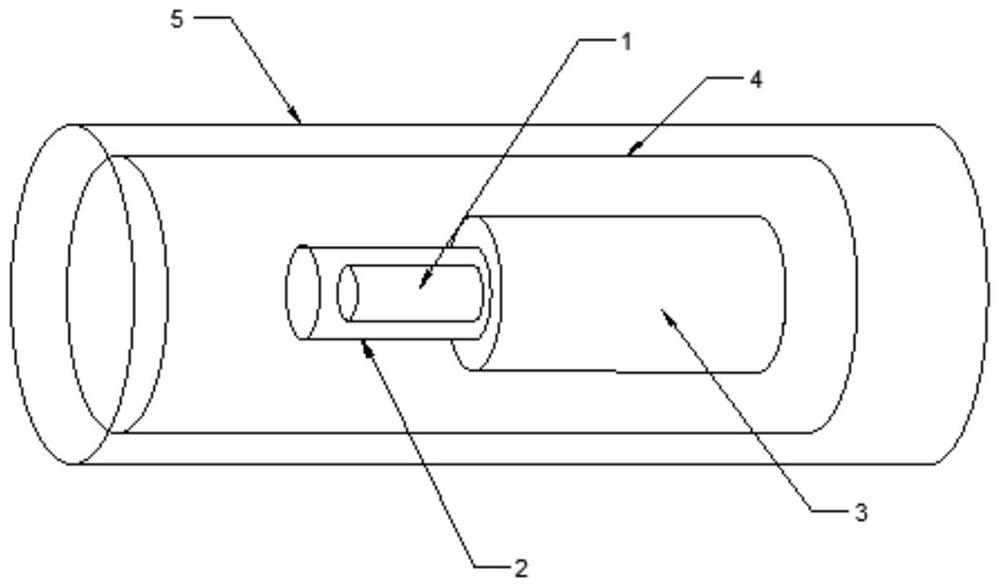

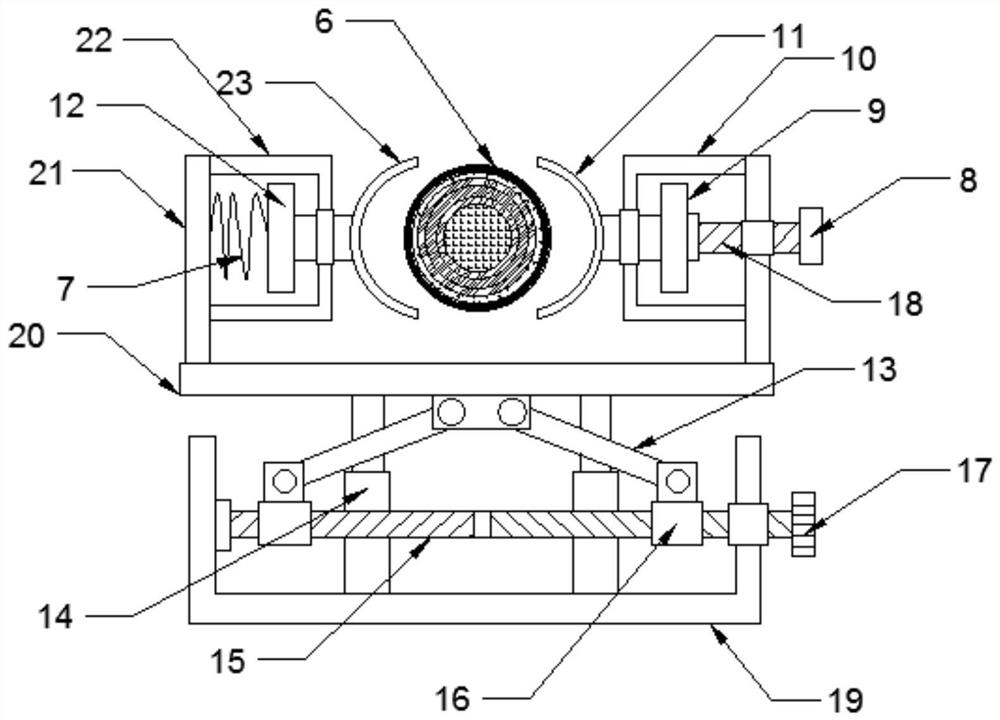

[0029] Such as Figure 1-Figure 3 As shown, a flexible sensing wire for radar provided in this embodiment includes a wire body 6, a clamping assembly is provided on the outside of the wire body 6, and a clamping adjustable assembly is provided on the clamping assembly, and the bottom of the adjustable assembly is installed There is a top plate 20, and the bottom of the top plate 20 is hinged with a height-adjustable component. The height-adjustable component is provided with a base 19, and a compression cylinder 14 is also provided between the top plate 20 and the base 19. The wire body 6 includes a polyethylene outer insulating layer 5, Heat-shrinkable sleeve 4, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com