Damper module of rolling drum washing machine

A drum washing machine and damper technology, which is applied to the control device of washing machine, other washing machines, washing devices, etc., can solve the problem of inability to accurately perceive the eccentricity, and achieve the effect of improving reliability and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

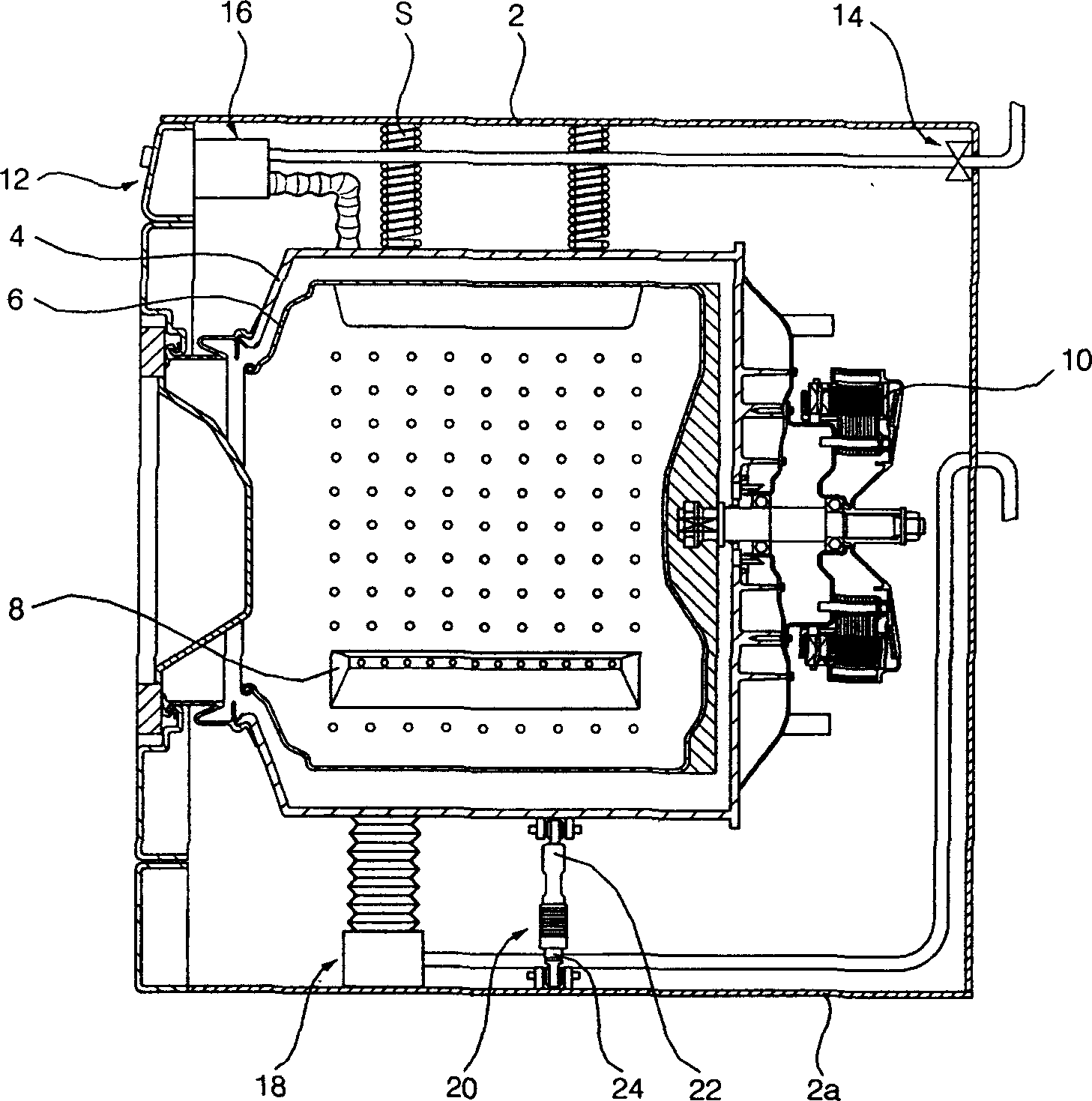

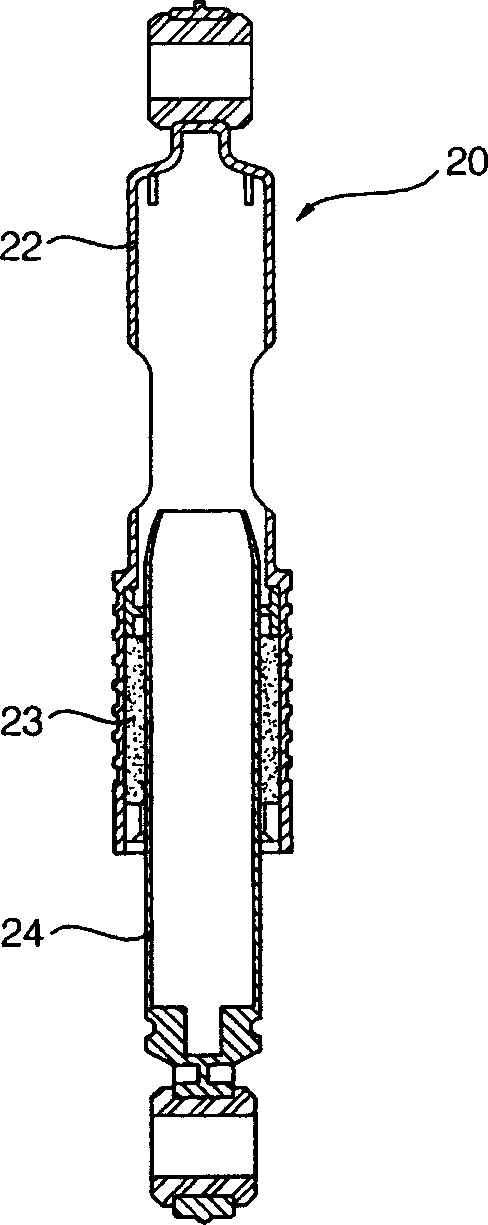

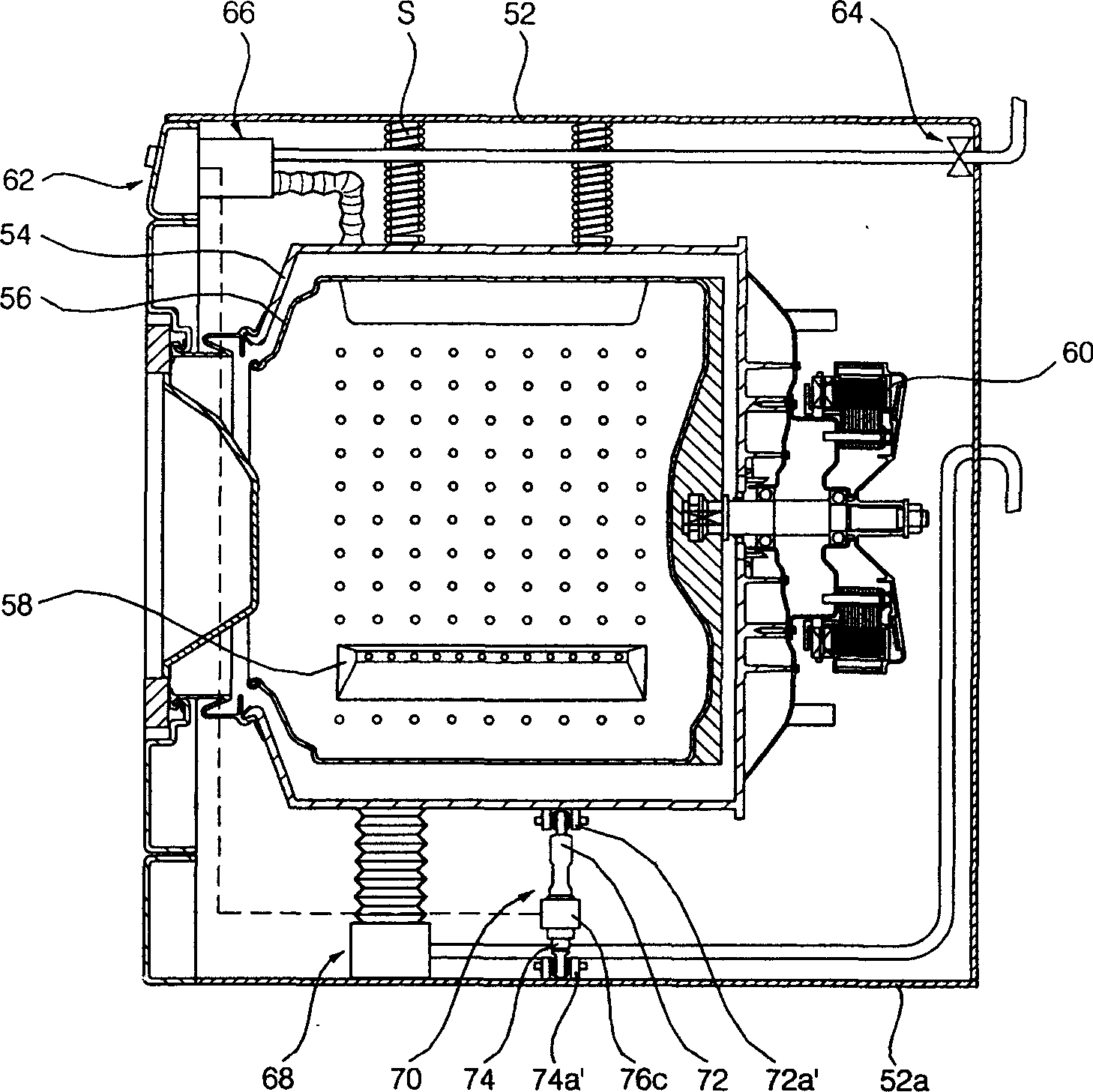

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail: image 3 It is a side sectional view of the drum washing machine of the present invention. Figure 4 It is a sectional view of the drum washing machine damper assembly of the present invention.

[0032] Such as image 3 As shown, the washing machine of the present invention includes: a washing tub 54 arranged inside the casing 52 and filled with washing water; Drum 56; protruding and forming at a certain interval on the inner wall surface of the drum 56, when the drum 56 rotates, the lifting member 58 that lifts the laundry; is connected to the drum 56 at the rear end of the washing bucket 54, and makes the drum 56 The rotating motor 60 is arranged on the inside of the front of the housing 52 to adjust the operation of the washing machine, especially the control unit 62 for adjusting the operation of the washing machine according to the eccentri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com