Oscillating shower transfer type substrate treatment device

A substrate processing device and spray-type technology, which are applied in the directions of optics, instruments, electrical components, etc., can solve the problems of inability to eliminate, remain, and poor wettability of the glass substrate 4, and achieve the effect of eliminating shortcomings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

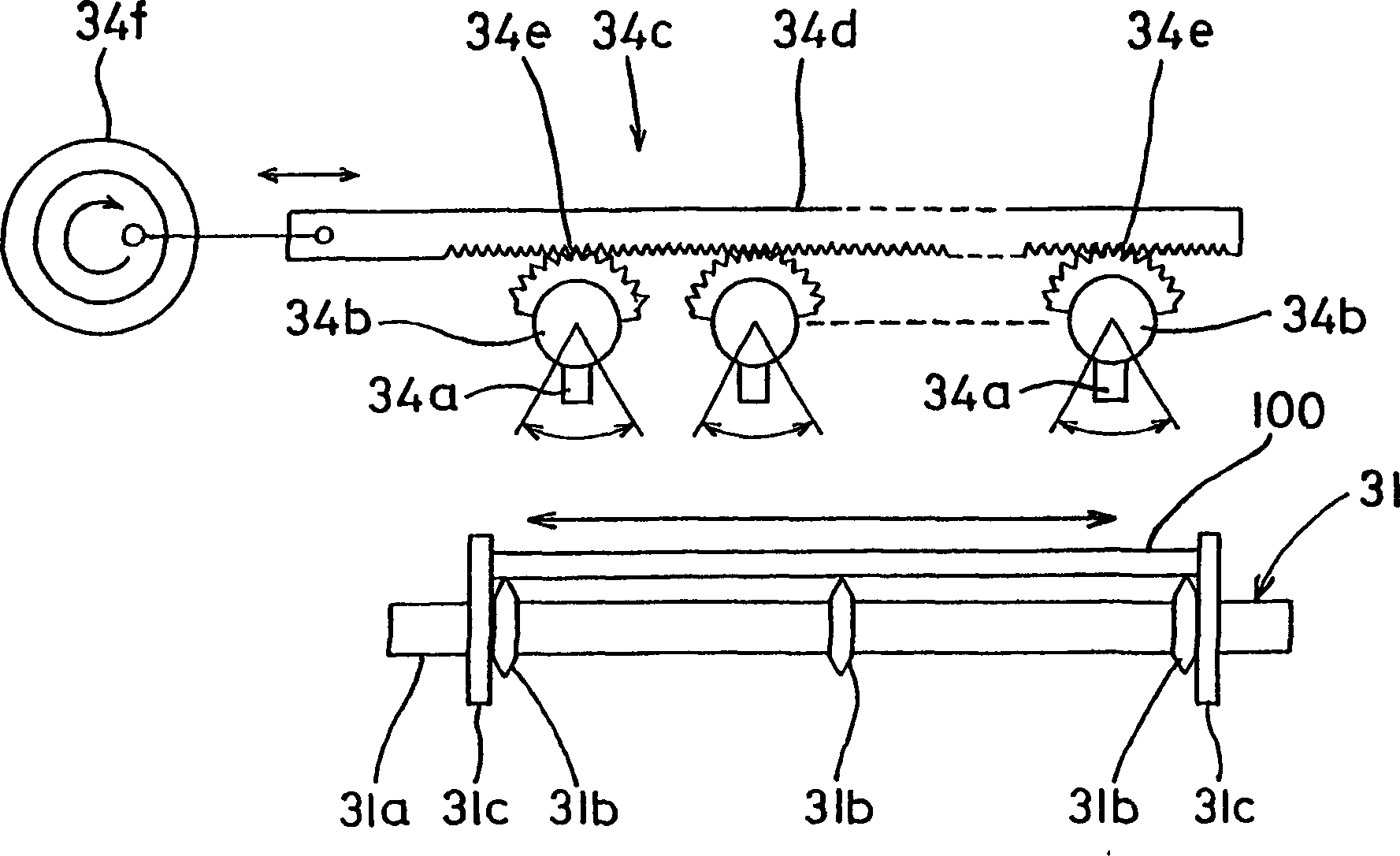

[0027] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

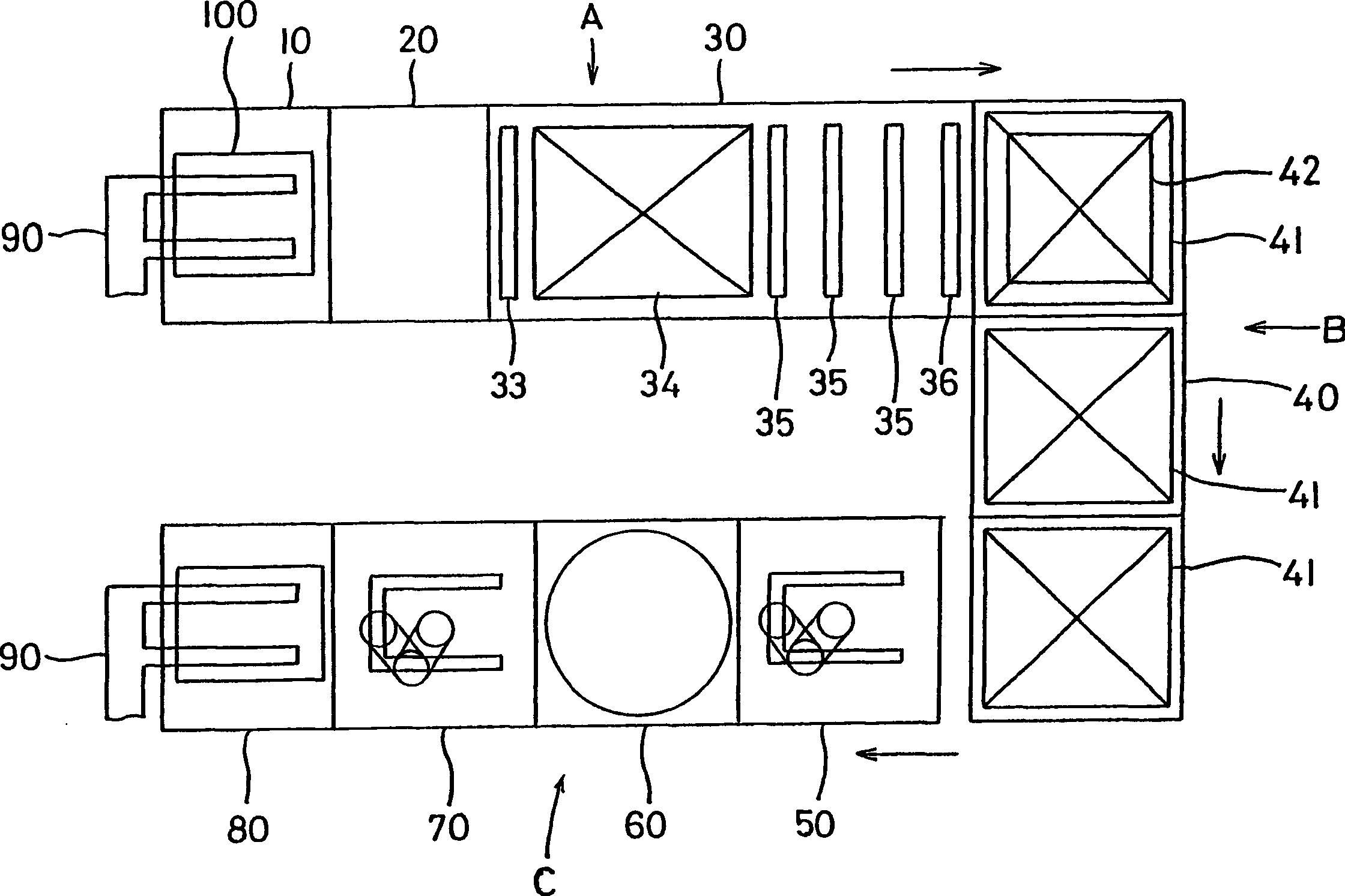

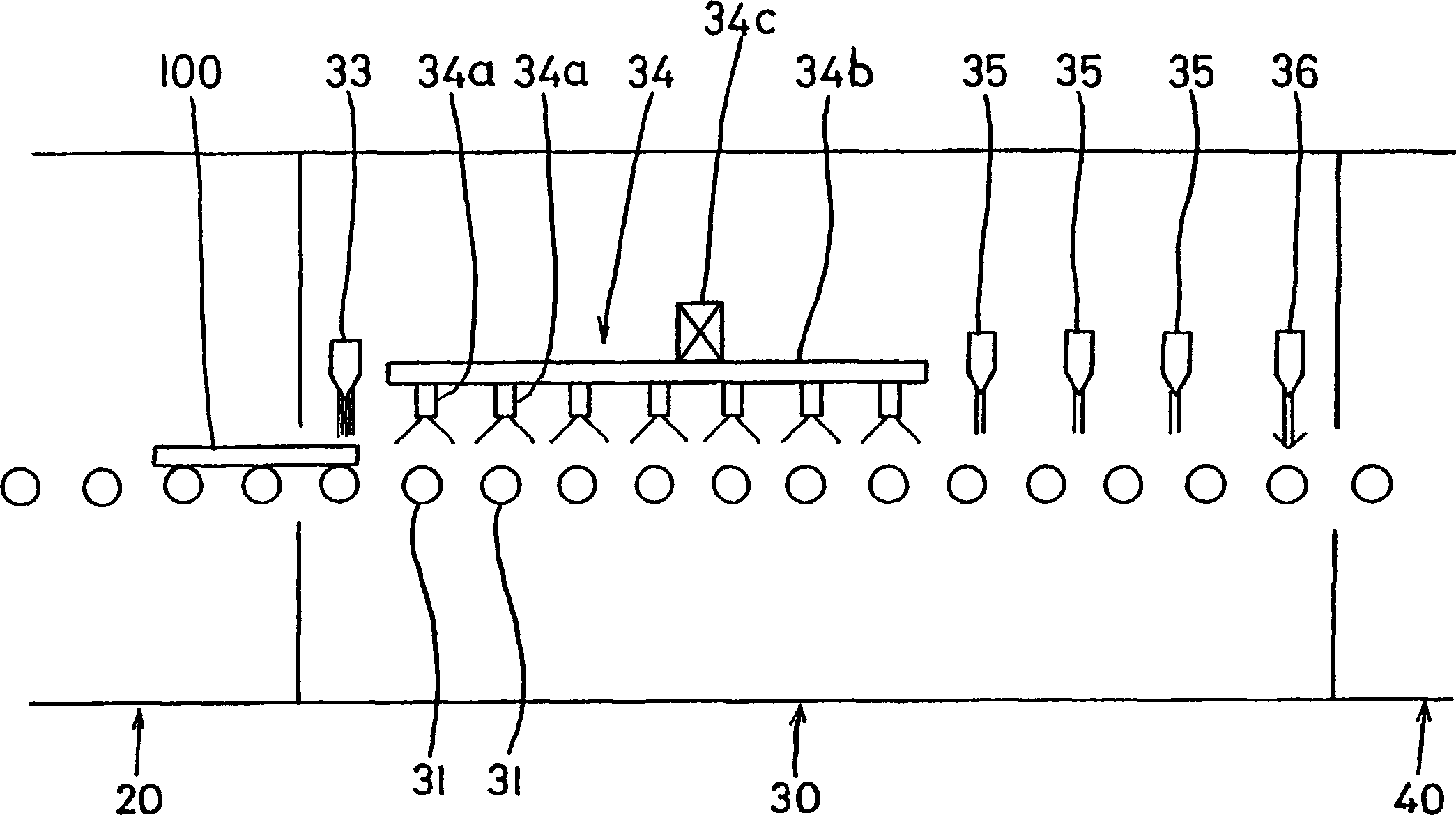

[0028] The swing-shower transfer type substrate processing apparatus of this embodiment is an apparatus for performing an Al etching process on a glass substrate 100 for a liquid crystal display device (hereinafter simply referred to as the substrate 100 ). Such as figure 1 As shown, the substrate processing apparatus adopts a linear first transfer line A, a second transfer line B connected to the first transfer line A at a right angle, and a second transfer line B connected to the second transfer line B at a right angle and parallel to the first transfer line A. The U-rotation layout formed by the combination of the third transmission line C.

[0029] The first transmission line A is configured by linearly connecting the receiving section 10 , the liquid blocking section 20 , and the corrosion section 30 . The second transfer line B is a water washing unit 40 and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com