Curve shaped bullet holder in autosegregation

A curved body shape, self-body technology, applied in the field of improvement of the structure of the bullet support, can solve the problems of increasing launch cost and unstable separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

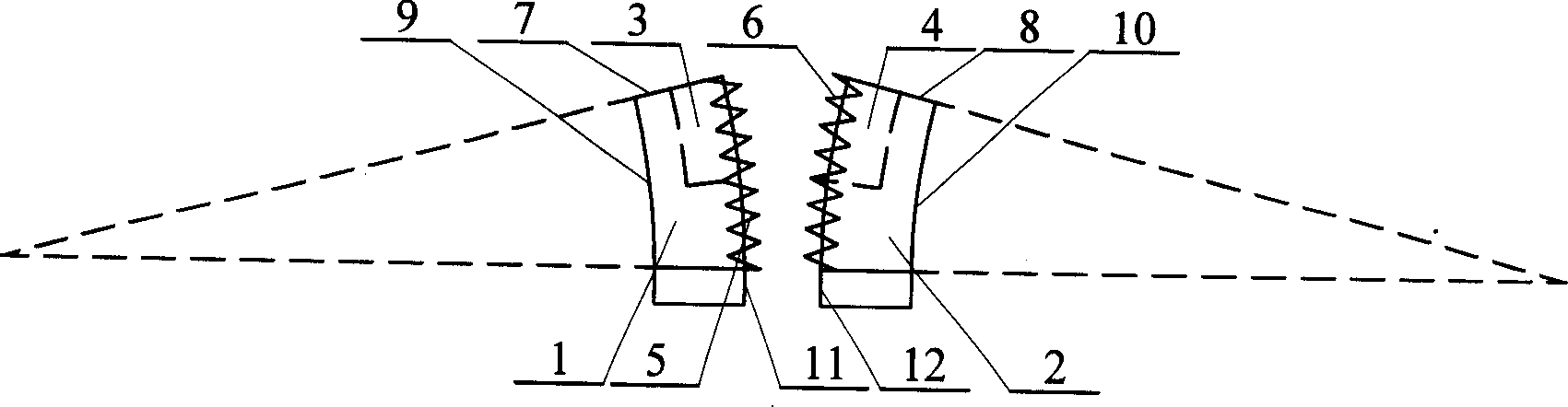

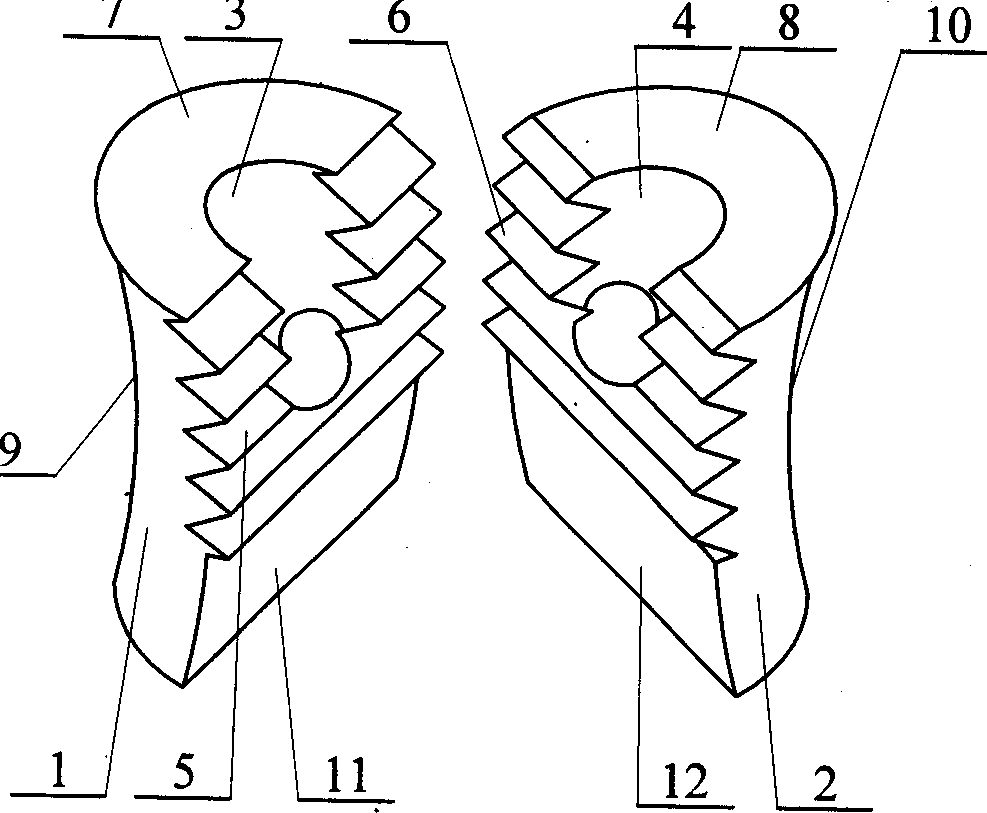

[0005] Specific implementation mode one: (see figure 1 , figure 2 ) The present embodiment is made up of left split 1 and right split 2; the horizontal section of left split 1 and right split 2 is two corresponding semicircles, and the upper part of the inner surface 11 side of left split 1 is opened Left half projectile hole 3 is arranged, and the inner surface 11 of left sub-lobe 1 is provided with left tooth-shaped body 5, and the upper part of the inner surface 12 side of right sub-lobe 2 has right half projectile hole 4, and the left half projectile on left sub-lobe 1 The hole 3 corresponds to the right half projectile hole 4 on the right split 2, and the inner surface 12 of the right split 2 is provided with a right toothed body 6 that is engaged with the left toothed body 5 on the left split 1, and the left split 1 It is a curved body shape 9, and the right split lobe 2 is a curved body shape 10 symmetrical to the left split flap 1. The material of the left split 1 a...

specific Embodiment approach 2

[0006] Specific implementation mode two: (see figure 1 , figure 2 ) The difference between this embodiment and the first embodiment is that the upper end surface of the left split 1 is a plane 7, and the upper end of the right split 2 is a plane 8. Other compositions and connections are the same as in the first embodiment. Designing the upper end faces of the left split 1 and the right split 2 as a plane structure can increase the movement resistance of the bullet holder, so that it can be better separated from the projectile.

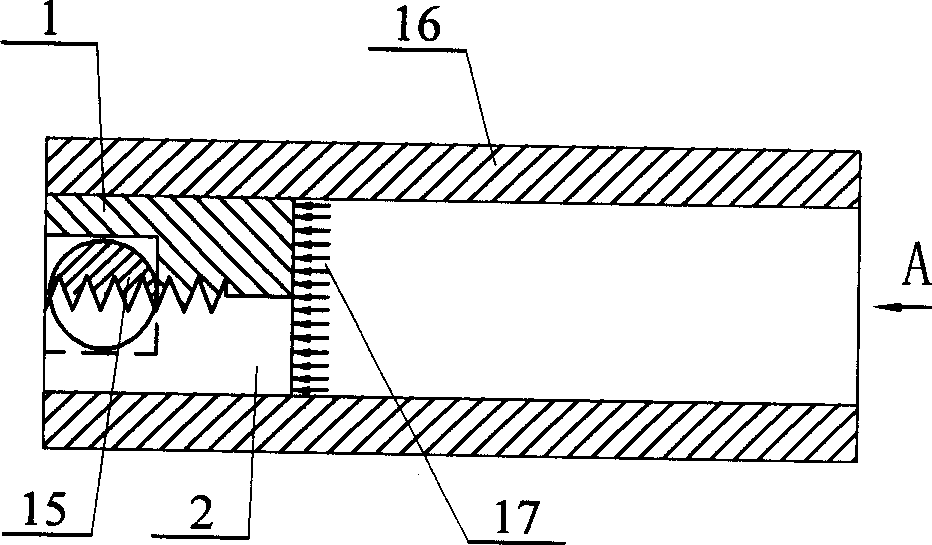

[0007] Working principle: When the bullet holder is loaded into the launch tube, the clamp can be used to make the bullet holder into a cylindrical shape, and then pushed into the launch tube, the bullet holder is affected by the high-pressure driving gas at the bottom, and driven by the high-pressure driving gas, the bullet holder carries the projectile in the launch tube exercise, such as image 3 shown. When the front end of the bullet holder e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com