Tray type CD-ROM

A tray-type, optical drive technology, applied in the direction of recording information storage, instruments, etc., can solve the problems of restrained discs, broken fragments, user hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

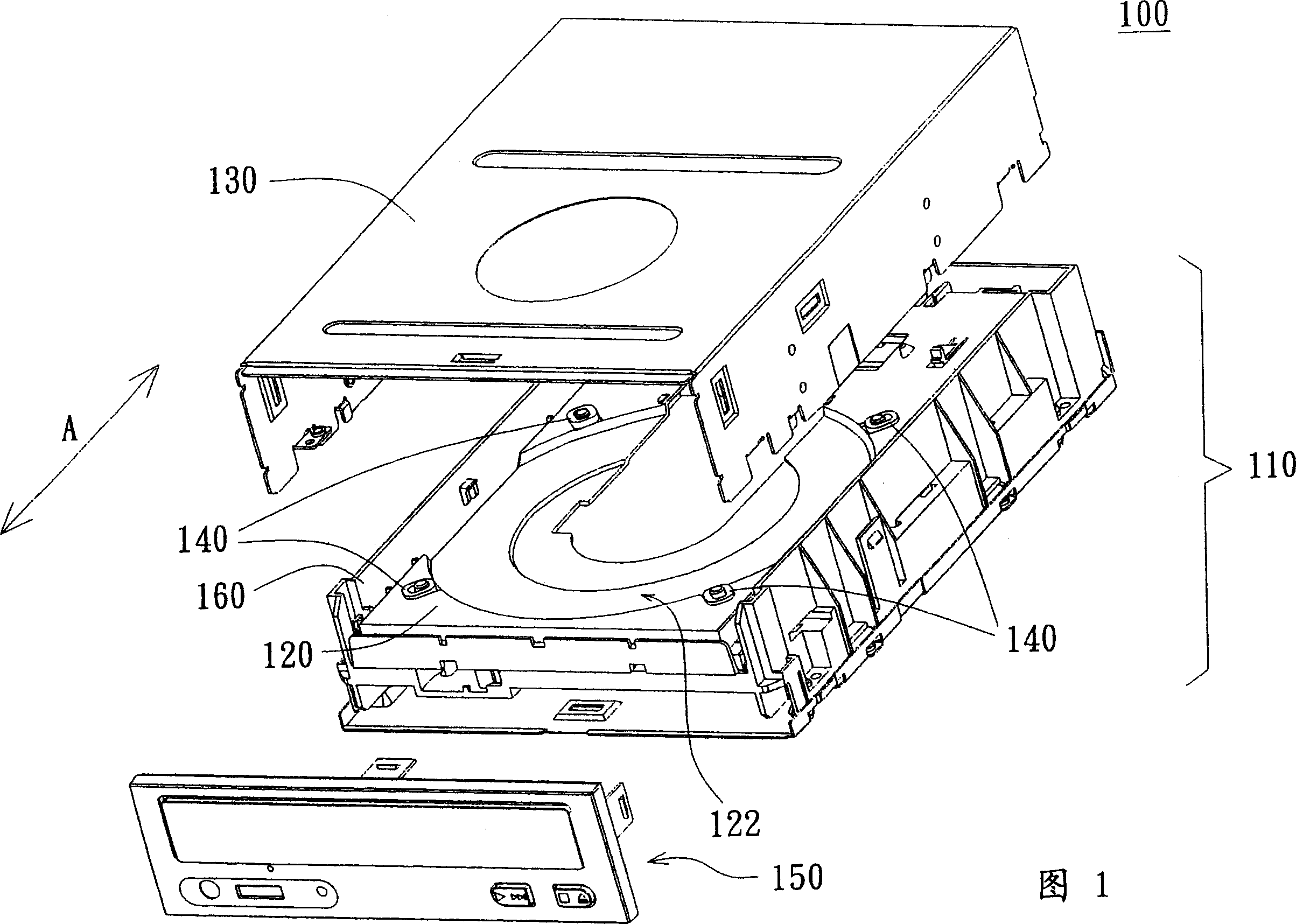

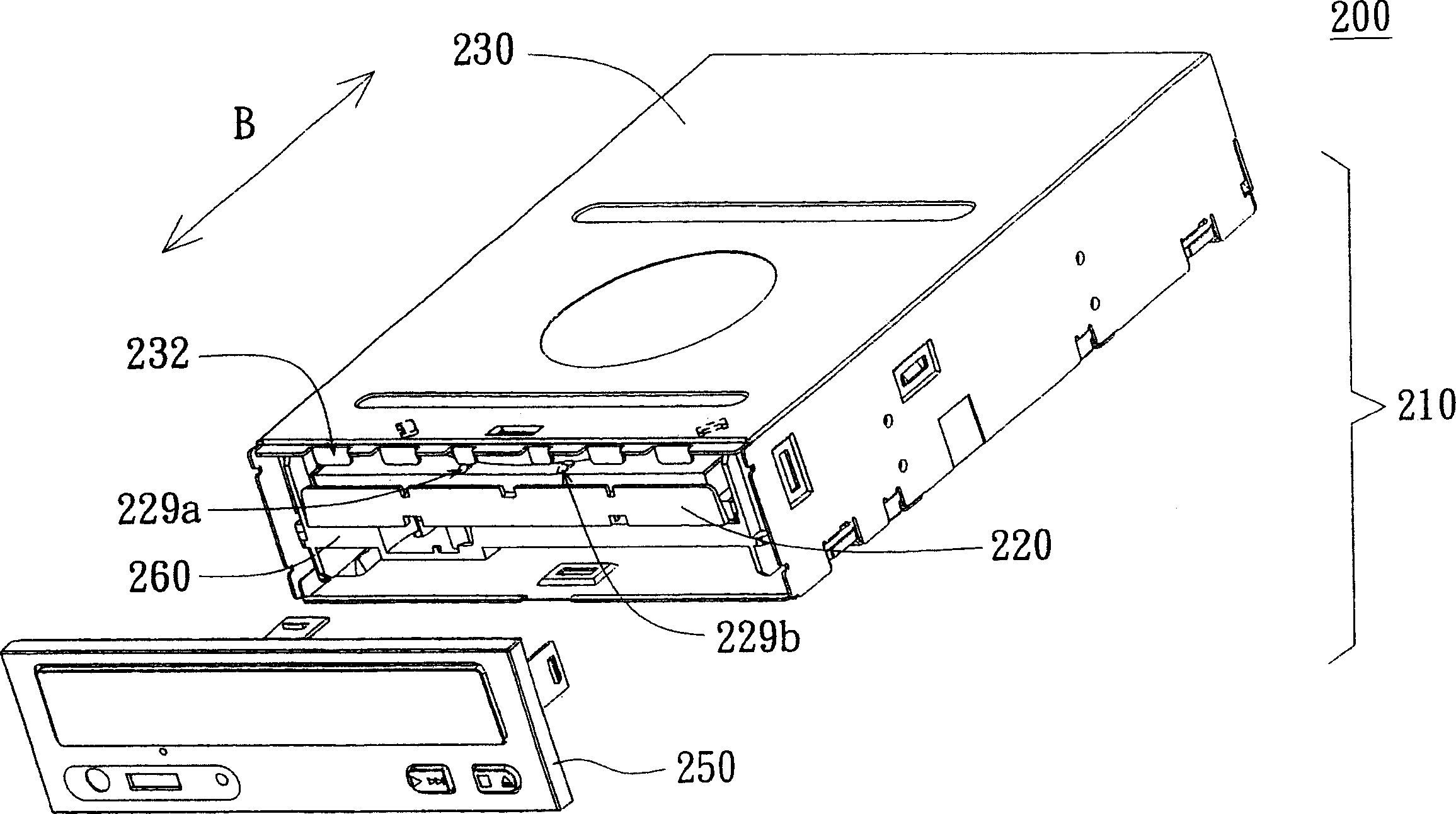

[0018] Please refer to figure 2 , which is a schematic diagram of a tray-type optical drive in a preferred embodiment of the present invention. The tray type optical drive 200 includes an optical drive body 210 , a tray 220 , an upper cover 230 , a panel 250 and a base 260 . The upper cover 230 is used to cover the optical drive body 210 , and the forming board 250 is disposed on the front side of the optical drive body 210 . The tray 220 is set on the optical drive body 210, and along the figure 2 In the way of moving in direction B shown in , the loaded disk enters the optical drive body 210 from the outside.

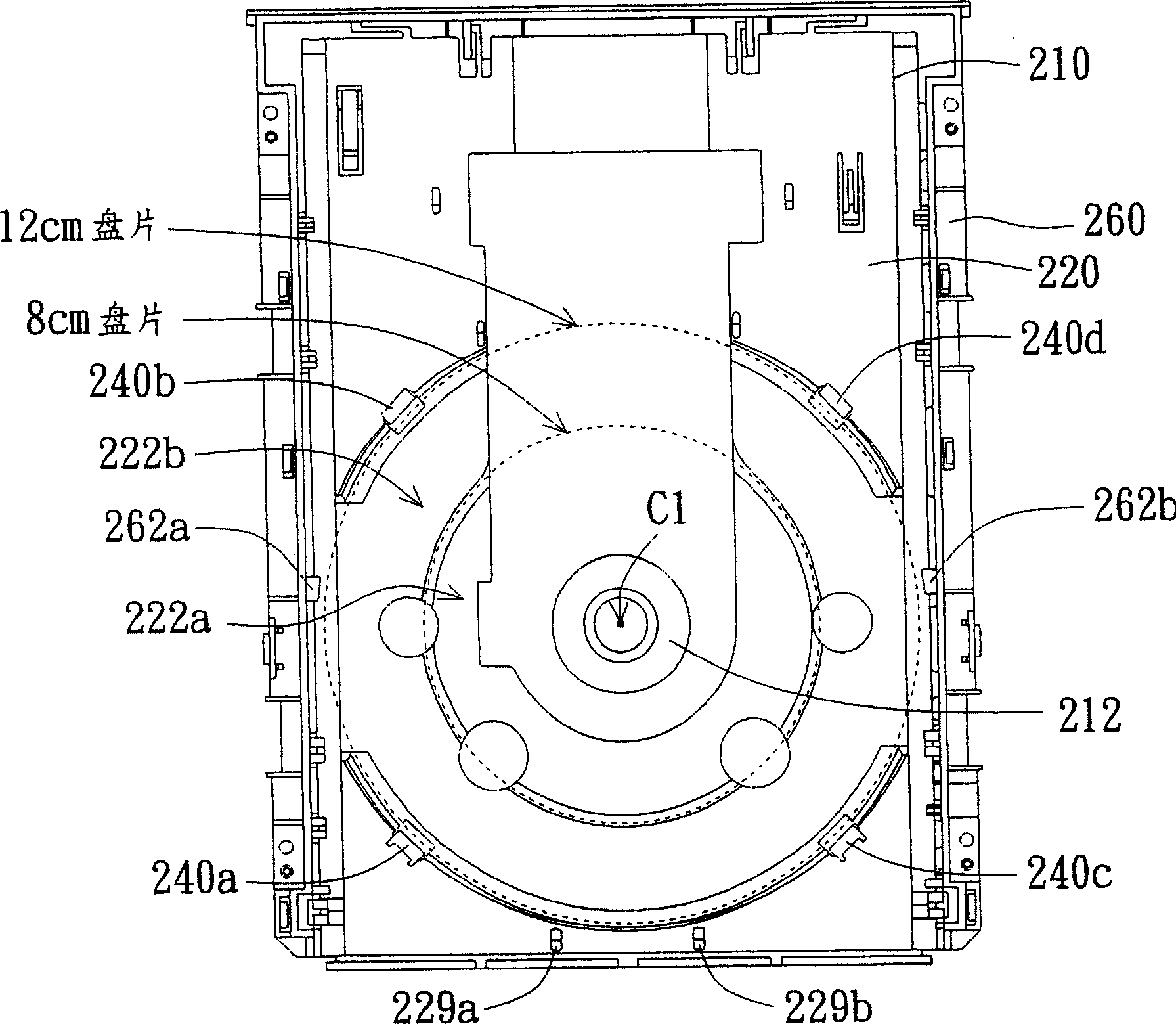

[0019] Please refer to Figure 3A , which shows a schematic view of the tray 220 , the optical drive body 210 and the base 260 . The optical drive body 210 is disposed in the base 260 , and in this figure, the tray 220 has been moved into the optical drive body 210 . Two sides of the base 260 are respectively provided with protrusions 262a, 262b. The tray 220 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com