Anode for liquid fuel cell, membrane electrode assembly for liquid fuel cell, and liquid fuel cell

A solid polymer and liquid fuel technology, applied in solid electrolyte fuel cells, fuel cell components, fuel cells, etc., can solve the problems of slow fuel diffusion, difficulty in application, and large fuel penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

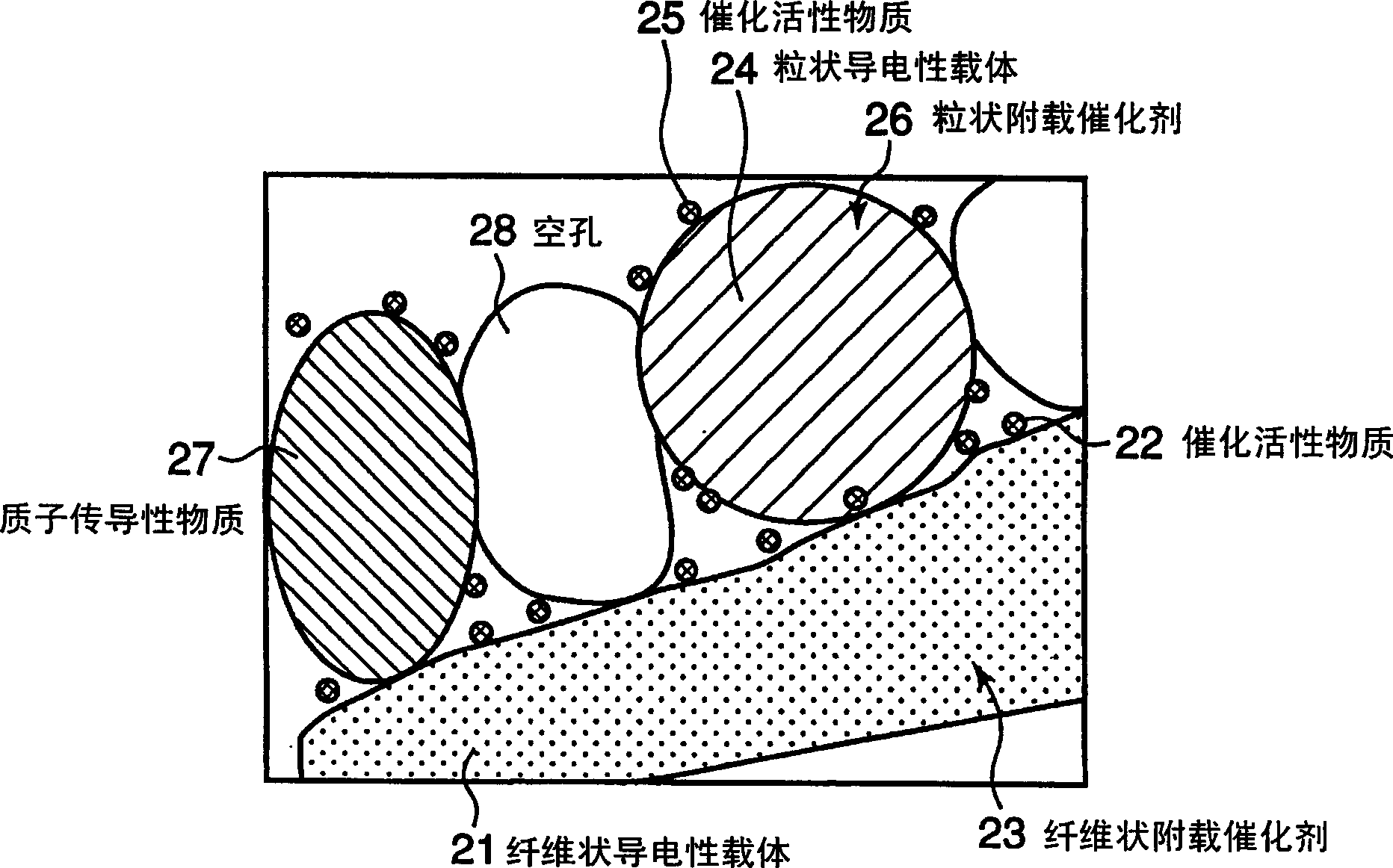

[0053] (anode)

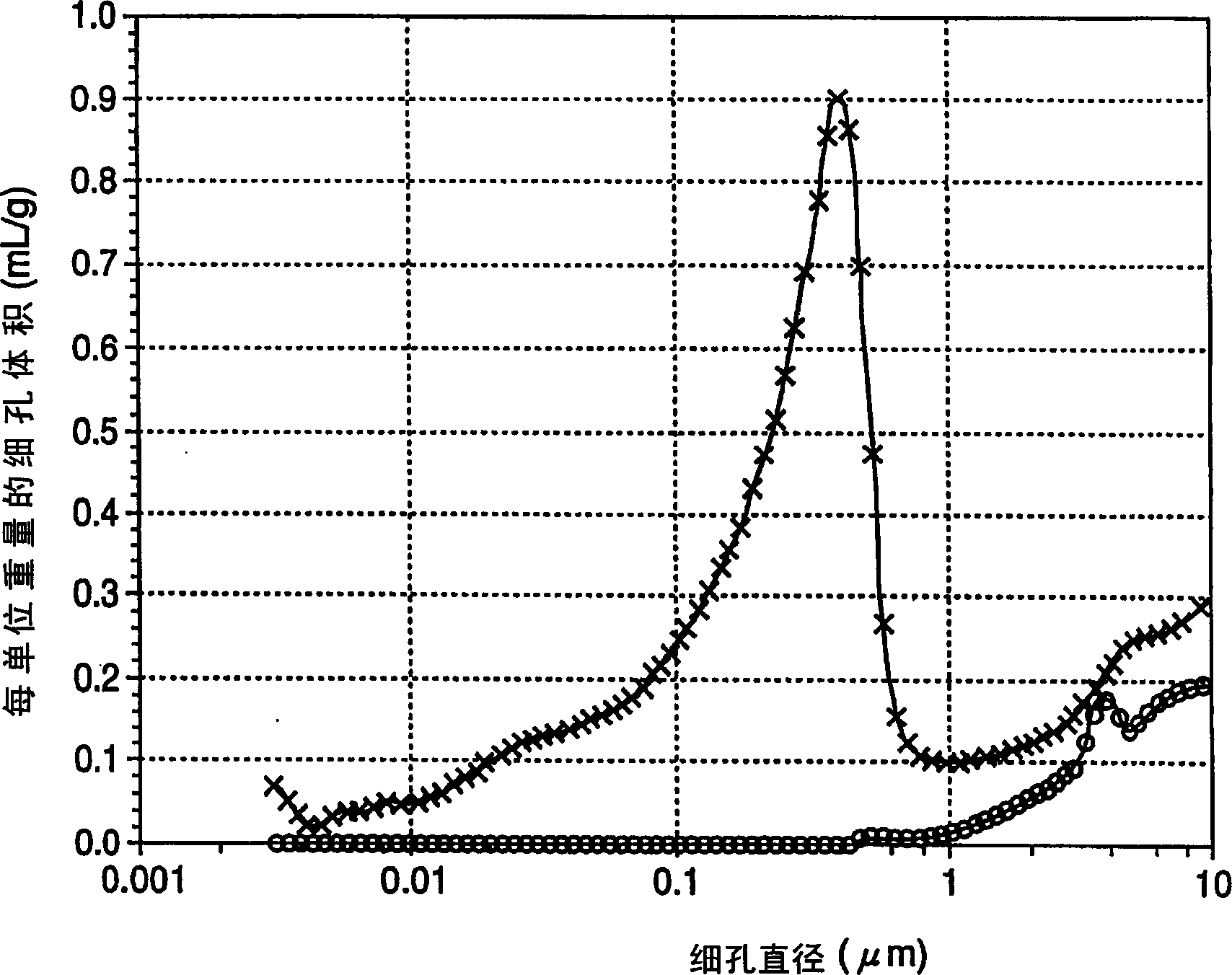

[0054] The anode is made by means of suction filtration. As a fibrous supported catalyst, the selected one has an average diameter of 250nm and a specific surface area of 300m 2 / g, the pore volume is 0.3cm 3 / g, with an average aspect ratio of 50 herringbone-shaped carbon nanofibers with 40% by weight of PtRu 1.5 Microparticles, and as a granular supported catalyst, the selected primary particle has an average diameter of 50nm and a specific surface area of 50m 2 / g, DBP oil absorption of 50ml / 100g carbon black with 40% PtRu 1.5 . First, 30 mg of fibrous supported catalyst and 45 mg of granular supported catalyst were weighed, 150 g of pure water was added, stirred sufficiently, dispersed and heated to obtain a mixed solution with a solid content of 0.05% by weight and a temperature of 85°C. 10cm through hydrophobic treatment 2 The obtained mixed liquid was suction-filtered with a porous carbon paper (350 μm, manufactured by Toray Industries Co., Lt...

Embodiment 2

[0064] The average diameter of carbon nanofibers is set to 200nm, and the specific surface area is set to 150m 2 / g, the average aspect ratio is set to 30, the average primary particle diameter of carbon black is set to 50nm, and the specific surface area is set to 150m 2 / g, DBP oil absorption are set to 100ml / 100g, the fibrous supported catalyst and the granular supported catalyst are respectively set to 45mg and 30mg, and the solid content of the mixture of the fibrous supported catalyst and the granular supported catalyst and water is set as The anode was fabricated as described in Example 1 above except that the temperature was set at 25° C. and the amount of the proton conductive material NAFION (manufactured by DuPont) deposited at 25 mg. From the obtained anodes, a DMFC was fabricated as described in Example 1 above, and the anodes were evaluated. The results are shown in Table 1 below.

Embodiment 3

[0066] Set the average diameter of carbon nanofibers to 150nm and the specific surface area to 400m 2 / g, the average aspect ratio is set to 80, the average primary particle diameter of carbon black is set to 30nm, and the specific surface area is set to 250m 2 / g, DBP oil absorption are set to 175ml / 100g, the fibrous supported catalyst and the granular supported catalyst are respectively set to 60mg and 25mg, and the solid content of the mixture of the fibrous supported catalyst and the granular supported catalyst and water is set as An anode was fabricated as described in Example 1 above except that the temperature was set at 90° C. and the deposition amount of the proton conductive material NAFION (manufactured by DuPont) was set at 20 mg. From the obtained anodes, a DMFC was fabricated as described in Example 1 above, and the anodes were evaluated. The results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com