Hot-air circulation type electric oven for shoe-making

A technology of hot air circulation and electric oven, which is applied in shoemaking machinery, applications, footwear, etc., can solve the problems of poor drying quality and waste of energy, and achieve the effects of reducing energy consumption, solving waste of energy, and effectively utilizing large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

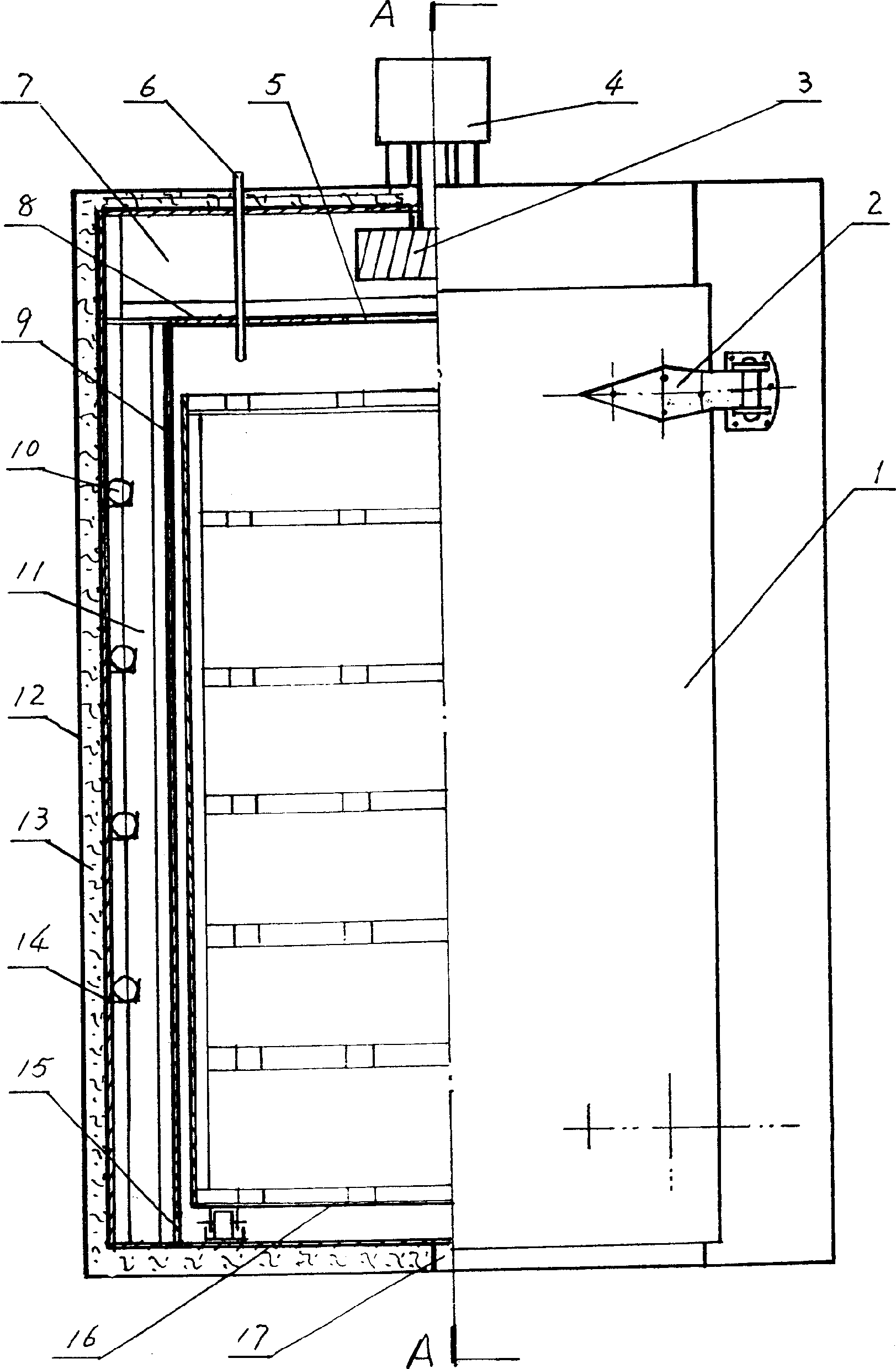

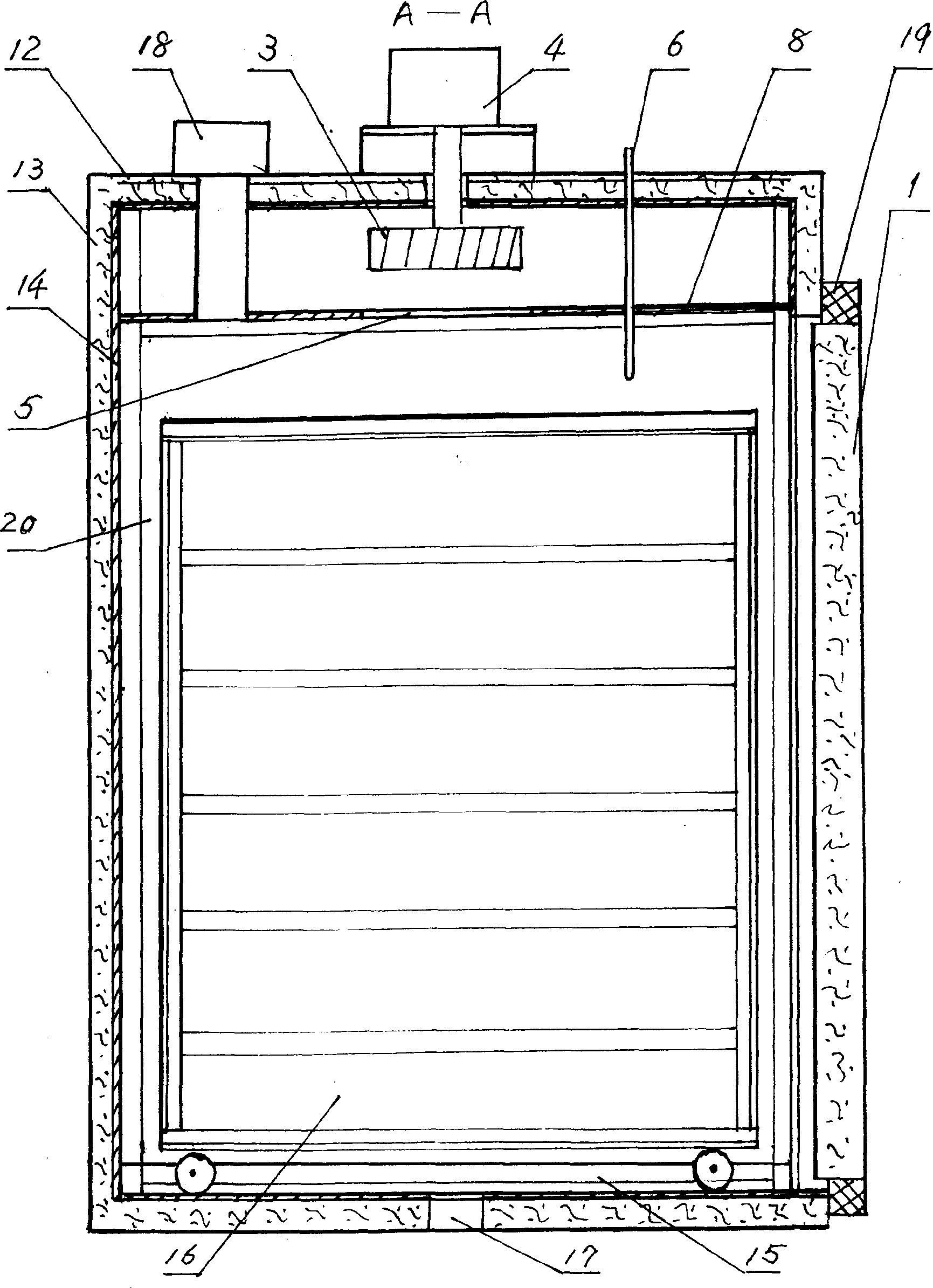

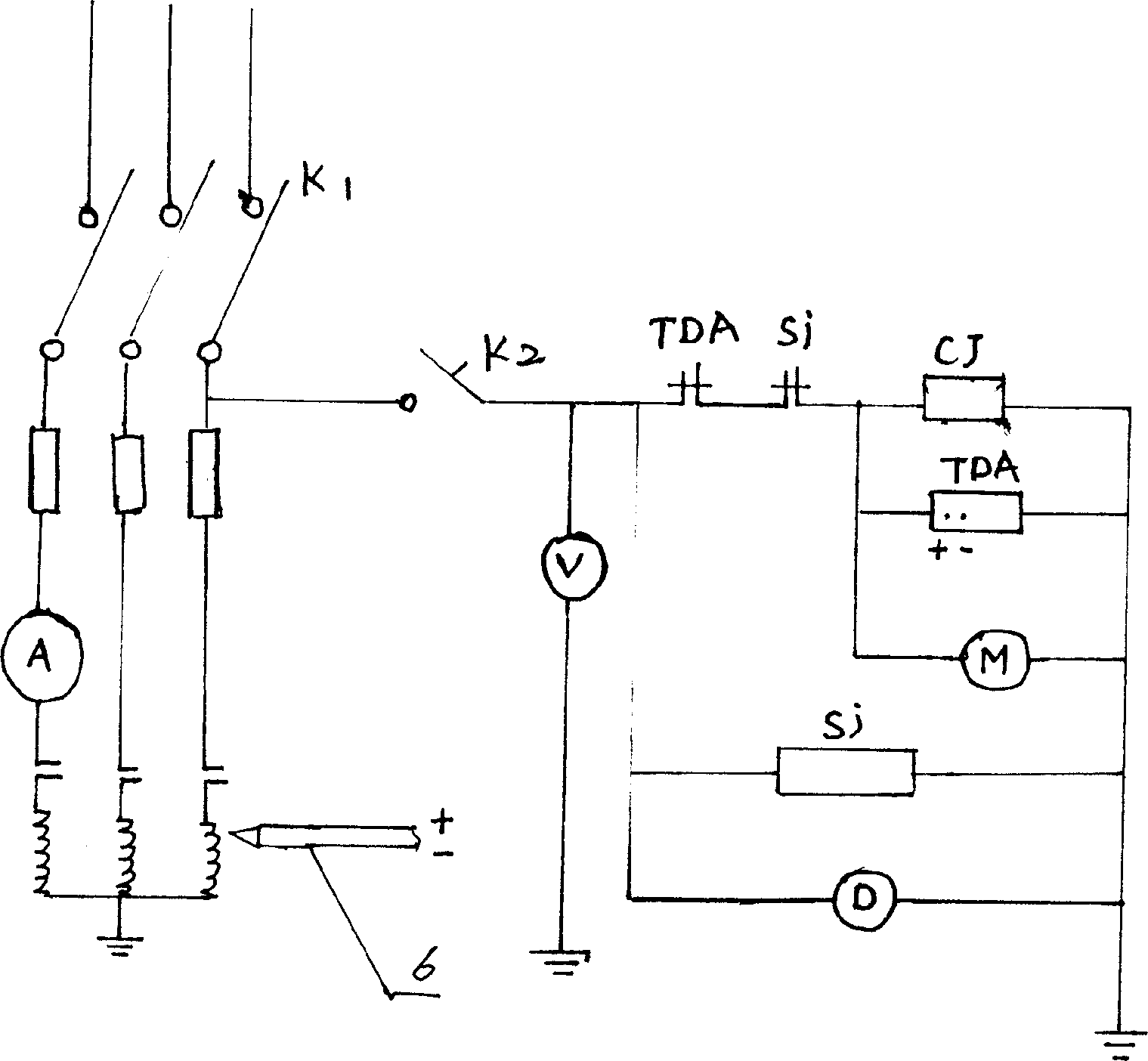

[0014] according to Figure 1-3 The specific structure of the present invention will be described in detail. The device comprises a casing with a casing door 1 and a temperature controller placed in the casing, a feeding cart 16, a centrifugal blower fan, a circulating air duct and the like. Wherein the box body and the box door 1 are assembled by an outer shell 12 made of profiles, an inner panel 14 and an insulating material 13, and its specifications and shapes should be determined according to specific use requirements. Left and right air ducts 11 are formed between the left and right inner panels 14 of the box body and the left and right air duct plates 9 . Electric heat pipes 10 are arranged in each side air duct 11, and the specification and quantity of electric heat pipes 10 are determined according to the quantity of shoes to be dried and the drying temperature. In the upper air channel 7 formed between the top of the box body and the upper air channel plate 8, a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com