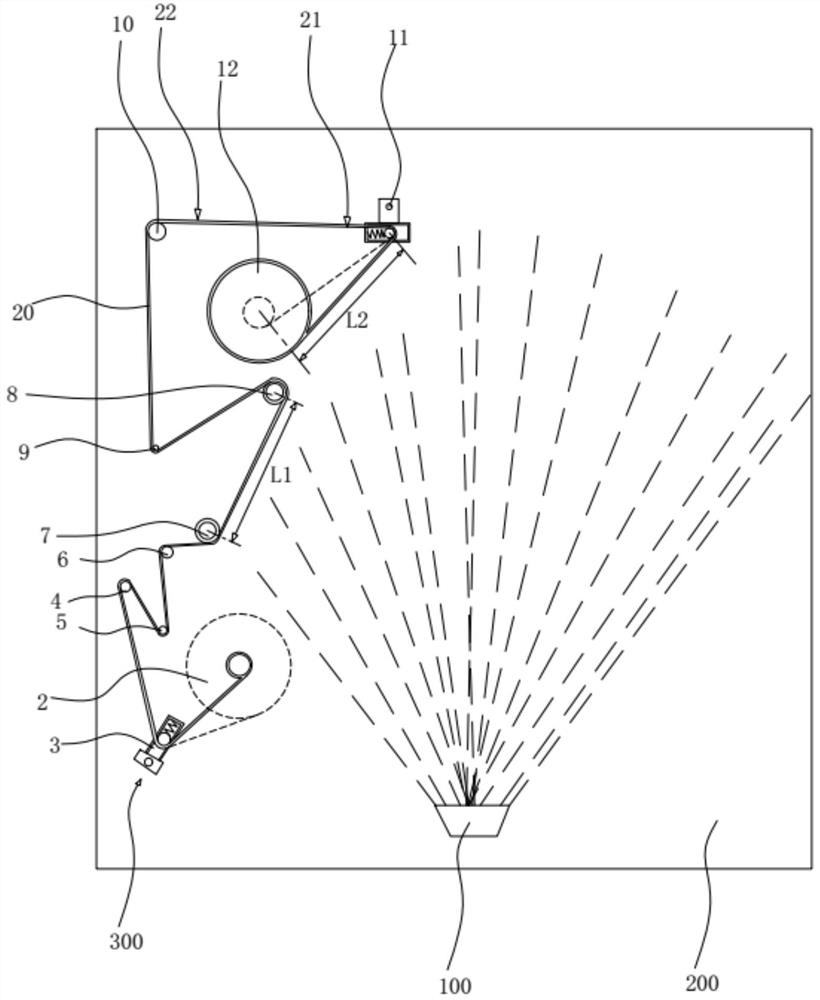

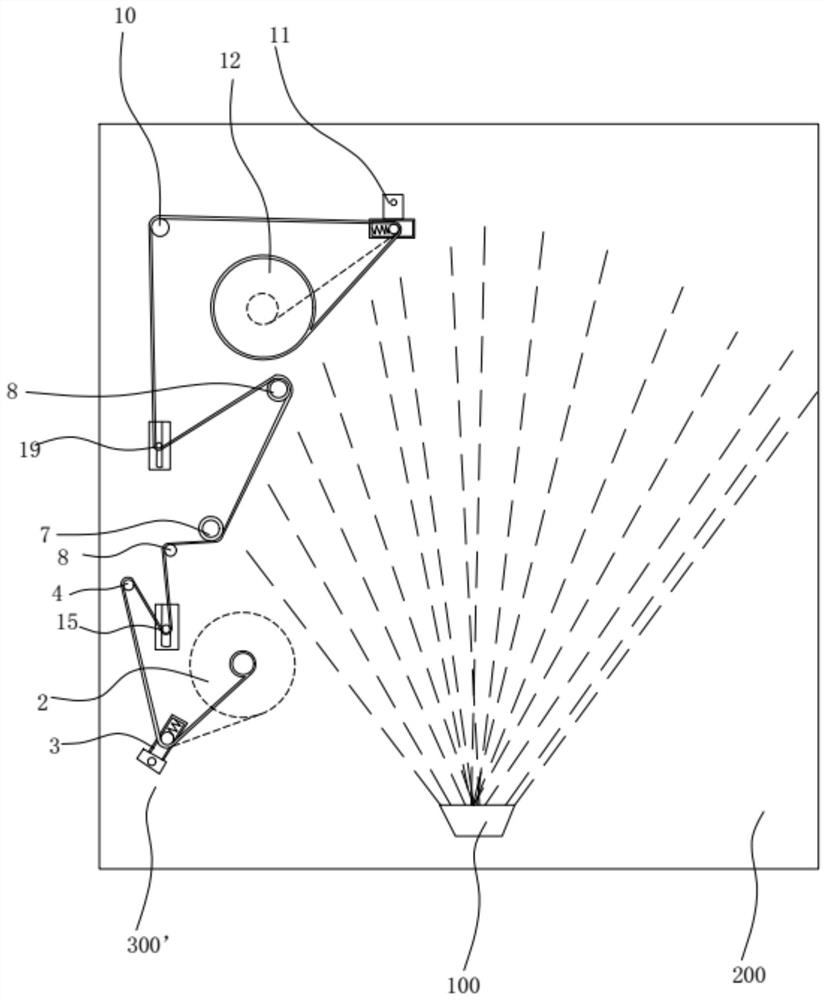

Double-sided reciprocating film coating device

A coating device and double-sided technology, applied in the field of double-sided reciprocating coating devices, can solve the problems of low utilization rate of effective space, high cost, low efficiency, etc., and achieve the effects of improving effective space utilization, reducing energy consumption and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Configure 2 sets of winding equipment of the present invention in the cylindrical vacuum chamber, and the winding width (transverse width) of the flexible strip is the same as that of the current single-sided winding equipment, so in a cylindrical vacuum chamber with the same size, The production efficiency of the winding equipment of this embodiment is 4 times of the present single-sided winding equipment production efficiency, and wherein, double-sided steaming (splashing) is 2 times, and 2 sets of winding equipments are 2 times again.

Embodiment 2

[0090] Configure 3 sets of winding equipment of the present invention in the cylindrical vacuum chamber, the winding width (transverse width) of the flexible strip is small with the current single-sided winding equipment (according to the vacuum chamber configuration of 1.6 meters in diameter, the width of the present embodiment Width size is the width of the single-sided winding equipment of 1.0 meters), so in a cylindrical vacuum chamber with the same size, the production efficiency of the winding equipment of this embodiment is the highest production efficiency of the current single-sided winding equipment. 5 times, of which, double-sided steaming (splashing) is 2 times, 3 sets of winding equipment is 3 times, the width is 1.0 meters, and the efficiency ratio=2*3*1.0 / 1.2=5.

Embodiment 3

[0092] Configure 4 sets of winding equipment of the present invention in the cylindrical vacuum chamber, and the winding width (transverse width) of the flexible strip is small with the current single-sided winding equipment (according to the vacuum chamber configuration of 1.6 meters in diameter, the width of the present embodiment Width size is 0.75 times the width of the single-sided winding equipment), so in a cylindrical vacuum chamber with the same size, the production efficiency of the winding equipment of this embodiment is the highest production efficiency of the current single-sided winding equipment. 6 times, of which, double-sided steaming (splashing) is 2 times, 4 sets of winding equipment is 4 times, the width is 0.83, and the efficiency ratio=2*4*0.83 / 1.2=5.53.

[0093] Table 1 The number of winding equipment configurations of the present invention and the productivity comparison table of single-sided winding equipment

[0094] Configuration sets Wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com