Steel reinforced concrete shear wall assembling type space modularized structure system and construction method

A shear wall and modular technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficult construction of joints, heavy workload of on-site hoisting, poor seismic performance, etc., to achieve easy construction and installation, improve The effect of hoisting efficiency and enhancing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

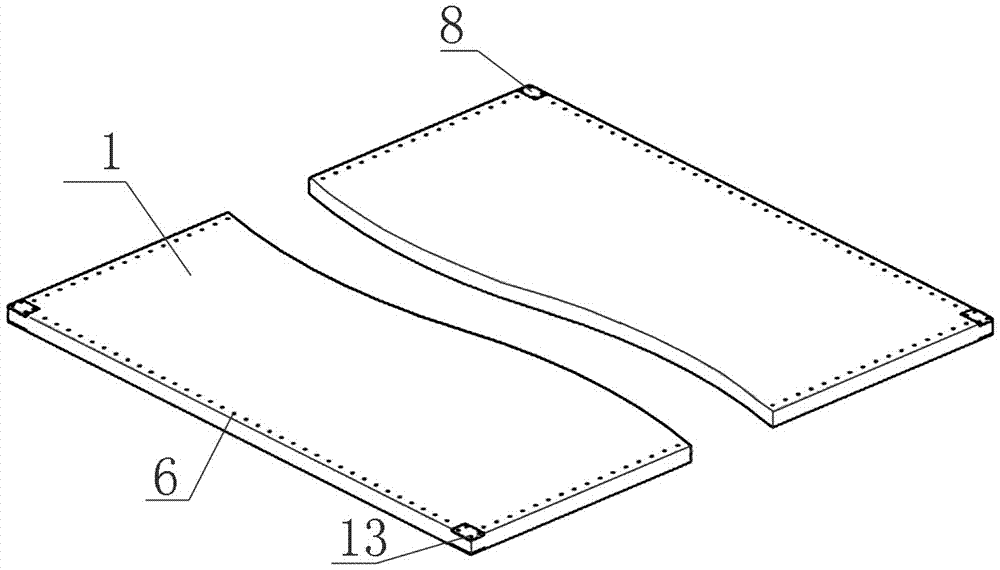

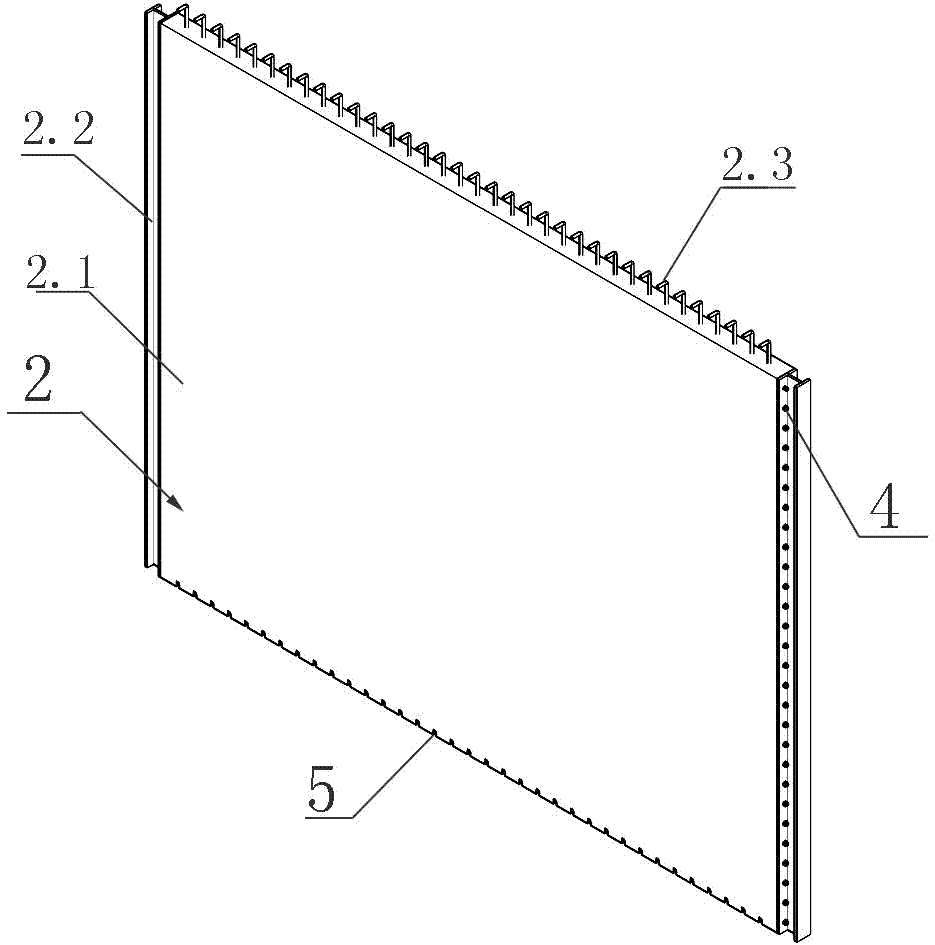

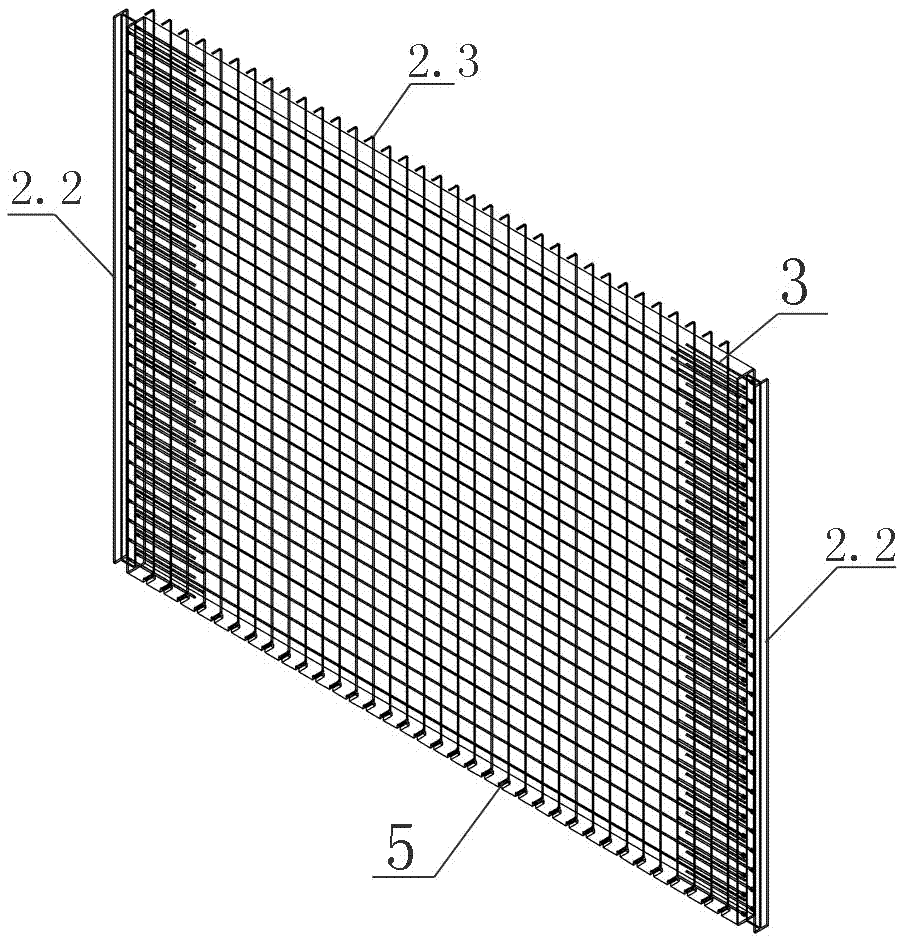

[0056] Such as Figure 1-10 , 15-17, this type of steel concrete shear wall assembled space modular structure system includes a first space module unit; the first space module unit includes a top floor 1 and four wall panels 2 A bell jar-shaped five-sided space module unit; the wall panel 2 is a prefabricated steel concrete shear wall panel, and the wall panel 2 includes a shear wall panel main body 2.1 and an I-shaped steel member 2.2; the shear wall panel On the vertical sides of the left and right ends of the main body 2.1, horizontal connecting bars 3 are pre-embedded along the vertical intervals, and one end of the connecting bars 3 is anchored in the concrete of the main body 2.1 of the shear wall panel, and meets the anchorage length requirements of relevant specifications. The other end of the tendon 3 exceeds the vertical side of the left end or the vertical side of the right end of the shear wall panel main body 2.1, and the excess part is provided with threads; the ...

Embodiment 2

[0069] Such as Figure 10-17 As shown, this type of steel concrete shear wall assembled space modular structure system includes a first space module unit; the first space module unit includes a bell jar consisting of a top floor 1 and four wall panels 2 Type five-sided space module unit; the wall panel 2 is a prefabricated steel concrete shear wall panel, and the wall panel 2 includes a shear wall panel main body 2.1 and an I-shaped steel member 2.2; the shear wall panel main body 2.1 has two left and right sides Horizontal connecting bars 3 are pre-embedded along the vertical intervals on the vertical side of the end. One end of the connecting bars 3 is anchored in the concrete of the main body 2.1 of the shear wall panel, and meets the anchorage length requirements of relevant specifications. The other end of the connecting bars 3 One end exceeds the vertical side of the left end or the vertical side of the right end of the shear wall panel main body 2.1, and the excess part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com